High.' Safety - . Factor in

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

NEW METAI ,IC TYRES

THIS week "The Commercial Motor" is able exclu-iively to describe a new tyre if( which steel is used to replace the fabric cords, and the quantity of rubber required for each tyre is reduced by amounts up to 20 per cent. The Michelin Tyre Co., Ltd., Stoke-on-Trent, is responsible for this development, which represents probably the greatest advance ever made in the construction of pneumatic tyres.

Known as the4lichelin Metallic tyre, it has many advantages which w0 api4 to all operators of commercial vehicles. It eliminates—premature failure caused by heat generation and high tyre temperature, and does not suffer from ply separation; 'tread detachment or heat bursts.

The Metallic tytes are being manufactured to fit existing, wheels, without Causing clearance difficulties, and they may be retreaded in the same manner as ordinary tyres.. The steel cord, which does not suffer harmful effects because of temperature rise, opens possibiLities for the use of smallerdiameter rims, with advantage's of a smaller rotating mass, lighter and .cheaper tyre and wheel assemblies, a better choice of gearratios, and a lower centre of gravity and loading line.Further, because of their higher load capacities for given sectional widths, -Metallic tyres assist in solving the problem of accommodating adequate tyres

within, the limits of restricted overall width. '

In 1929 the Michelin concern, by 'arrangement with M. Dautry, chief engineer of one of the French railways, under

took to study the design of a railcar which would run on pneumatic tyres. One of the conditions specified was that the stipulated tyre load should not be exceeded. This, of course, supposed that the number of passengers would be limited to the designed seating capacity of the railcar. On local service these cars became grossly overloaded, and under such conditions there was no cotton or rayon tyre which could stand up to the work. Metallic railway tyres solved the problern, and this wai the first application of the new method of construction.

The first large-scale research began in 1932. One of the primary difficulties was that of bonding rubber to steel.' As an initial measure, tyres were made with steel cords wound with cotton, to which the rubber adhered. This was done in order to obtain data on the main problems of building up the steel cords and the quality of the steel to be used.

A year later a satisfactory method of bonding steel to rubber was evolved, and with the perfected method the bond was found to be far superior to the best-known bond of rubber to cotton or rayon. Prototypes met with a number of teething troubles, which took some years to overcome.

Production of the new tyre was started in 1936, and by the following year several hundred large-section Metallic • giants were fitted to vehicles engaged on longdistance haulage. The tyres were purposely put into service where the most arduous conditions might be expected, and the test proved an.outstanding success, results far exceeding expectations.

Demand immediately exceeded the manufacturing possibilities, and even to-day supply has not caught up with it, production having been handicapped by the destruction during the war of the factory Which proauced the steel cords. Many Metallics were shipped to America in 1939,. and by 1940, when the imiasion of France stopped further exports, several thousands were fitted to American vehicles.

The advantages arising from the manufacture and use of the Metallic tyre not only affect the individual user, but also benefit national economy. Less rubber is 'used, with a corresponding reduction in the . A34 quantity of carbon black and other imported onstituents Of the rubber mixture.

Steel, which is domestically produced, is :employed in the place of imported cotton. Furthermore, the Metallic can be advantageously exported to countries where high atmospheric temperatures aggravate the effects on textile casings of overloading and high speeds over long distances.

The generation of heat and the development of high temperatures in tyres, more particularly in high-pressure

giants, are the basic problems of tyre design. In the larger commercial-vehicle tyres there are as many as 12, 14 or 16 plies, which move slightly one Over the other on every turn of the wheel. Although the movement is relatively small, it is sufficient to generateheat, which soon causes a marked increase in temperature. In' some of the larger tyres, temperatures of 190 to 250 degrees F. are often attained, and in the case of synthetic rubber, the temperature, may rise even higher.

It, is obvious that the greater the load, the' greater the generation of heat, as the amount of tyre ,flexion is higher. Similarly, high speeds cause more rapid generationof heat, as the frequency of the flexion • is increased and the tyre 'cannot dissipate the heat quickly enough.

• With. cotton casings, this increase in tyre temperature is most undesirable, because cotton, at 250 degrees F., loses almost half its tensile strength. Again, high internal ternperature affects the adhesion of the plies one to the other and weakens the bond between the tread and casing.

ln 1908, when it was impossible to make big single pneumatic tyres to stand up to heavy loads, the Michelin Company produced twin equipment. In place of a big single tyre, with many plies having a high equilibrium temperature, use was made of two smaller tyres, adequate for the load, but each having a smaller number of plies, and, therefore, a lower equilibrium temperature.

Subsequently, developments in America replaced the crossed-thread warp and weft fabric by a fabric with parallel cords. This not only eliminated the wear of the crossed threads, but, more important, greatly reduced the rubbing between the threads—the principal cause of heat generation.

With the advent of long-distance road haulage, soon after the first world war, it was apparent that the tyres of that period, although satisfactory for short hauls, could not withstand high speeds over long distances because of the great temperatures Which were reached.

Research was directed to making tyres with fewer plies, because it was the friction between the plies, added to the accumulation of heat by the thickness of the many-plied casing, which caused the harmful high temperature. Reduction of the number of plies led automatically to largersection. tyres and lower pressures for the same loads. The increased surface area thus afforded facilitated the radiation of internally generated heat.

There is an obvious limit to this increase of tyre section. It is relatively easy to replace 36-in. by 8-in. twins by 10.00-in. by 20-in, lowpressure equipment, but to replace the latter size by tyres of even lower pressure and bigger section would leave insufficient space for the chassis within the legal limits of overall width.

The next move on the part of the technicians was to search for new and better, materials for casing construe lion. Rayon proved interesting because it had the big advantage of losing only 15 per cent, of its tensile strength at the high temperatures generated in the larger tyres, against 45 per cent, in the case of cotton at a temperature of 248 degrees F. At normal atmospheric temperature its intrinsic strength was similar to that of cotton, so no big reduction could be made in the number of plies.

Michelin technicians made a bold move and attacked the problem by using steel cord, because steel is as strong at the highest. temperature generated within a tyre as it is at a low, temperature. Its strength permits the use of only two to four plies, thus overComing both the cause of heat generation and its harmful effects.

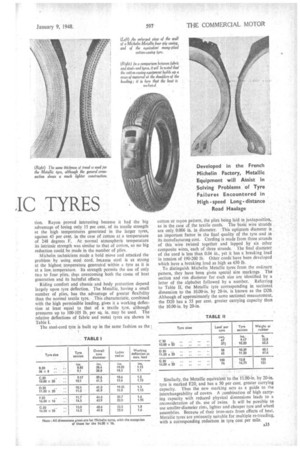

Riding comfort and chassis and body protection depend largely upon tyre deflection. The Metallic, having a small number of plies, has the advantage of greater flexibility than the normal textile tyre. This characteristic, combined with the high permissible loading, gives it a working deflection at least equal to that of a textile tyre, although pressures up to 100-105 lb. per sq. in. may be used, The relative deflections of fabric and metal tyres are shown in Table I.

The steel-cord tyre is built up in the same fashion as the

cotton or rayon pattern, the plies being laid in juxtaposition, as in the case of the textile cords. The basic wire Strands are only, 0.006 in. in diameter. This optimum diameter is an important factor in the final quality of the, tyre and in its manufacturing cost.. Cording is made from three strands of this wire twisted together and lapped by six other composite wires, each of three strands. The final diameter of the cord is less than 0.04 in., yet it has a breaking load in tension of 190-200 lb. Other cords have been developed which have a breaking load as high as 650 lb. . To distinguish Michelin Metallic tyres from the ordinary pattern, they have been given special size markings. The section and rim diameter for each size are identified by a letter of the alphabet followed by a number. Referring to Table II, the Metallic tyre corresponding in sectional dimension to the 10.00-in, by 20-in, is known as the D20. Although of approximately the same sectional measurement. the 1)20 has a 55 per cent. greater carrying capacity than the 10.00-in. by 20-in.

Similarly, the Metallic equivalent to the 11.00-in. by 20-in. tyre is marked E20, and has a 50 per cent, greater carrying capacity. Thus the new marking acts as a guide to the interchangeability of covers A combination of high carrying capacity with reduced physical dimensions leads to a reconsideration of thi. use of twins. It will be possible to use smaller-diameter rims, lightei and cheaper tyre and wheel assemblies. Because of their imrminitv from effects of heat, Metallic tyres are eminently suitable for multiple re-treading, with a corresponding reduction in tyre cost per mile.