HINTS ON MAINTENANCE.

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

316.—Improving Fan Bracket on Dennis Coach Chassis.

The fan spigot bracket on the 1920 Dennis coach chassis consists of a vertical pillar adjustable for height and supported at its base only. The result of the considerable stress on the base portion sometimes causes this to break off across the bolt holes. This:, can, however, be obviated by fitting a strap stretching from the top of the pillar to the stud at the top of the water-jacket.

Tolieffect the improvement the fan pillar should he drilled and•tapped with a n-in. thread for a setscrew. The' strap should be made of 3-in, by *-in. flat iron or steel and must be set to clear the water-pipe elbow.

317.—Lubricating the F2-type Fiat.

In the case of the .clutch a mixture of one-quarter thin oil and three-quarters paraffin should be inserted about every 200 miles; every 600 miles wash out the whole clutch with paraffin and again fill with the lubricating mixture. This should also be done when the clutch does not declutch completely, because, in this case,ithe discs have become covered with a sticky coating which prevents them coming apart.

The cardan joint is protected by a bronze easing provided with in suitable hole for the insertion of the lubricant. This should be oil of an extra-heavy quality, and before insertion it should be warmed so that it should flow more easily. The casing should be about half full, and fresh oil should he added every 200 miles.

318.—Maintaining Engine Efficiency on Undertype Steam Wagons.

A frequent cause of loss of power in the engines of steam wagons is a choked; or partially choked, ekhaust pipe. This can he detected by opening the drain cocks while the engine is puffing hard. If the cause of the trouble is a choked exhaust, an improvement in the pulling power will immediately be

a44 noticed, as the back pressure is then relieved, and it only remains to remove the deposit. It is useless looking down the chimney to see if the blast nozzle is choked, as, unfortunately, the choking usually takes place in the bend and the material causing it is carbonized oil, which, owing to its inaccessible position, is extremely difficult to remove. One very good way of doing this is to put the pipe in the forge and to heat it to a dull red. This will burn, out some of the deposit. After combustion has ceased and the pipe is still at a dull red heat, plunge it into cold water, and, When cold, tap lightly with a. hammer around the bend. This process may have to be repeated two or three time's. The pipe can be tested by drawing through it a nut of suitable size attached to a piece of string or wire.

A choked exhaust may give exceedingly good steaming, as the velocity of the steam is increased by the restricted passage formed by the carbon deposit.

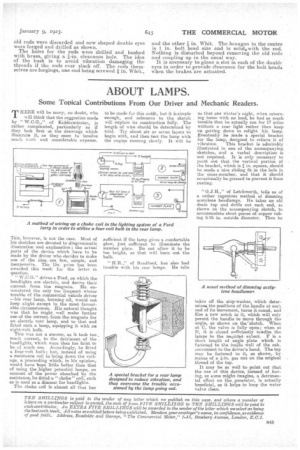

3I9.—Improved Brake-adjusting Rods for

• A.E.C. Chassis.

• One of our contributors had considerable trouble with the brake-adjusting rods on a number of A.E.C. chassis, and to overcome this he devised the type of rod and connections which we illustrate.. The trouble with the old rods was that the threads rusted into. the double eyes, and also when they were free it took a long time to adjust the brakes, and it was necessary to jack up the wheels.

By utilizing the new rods, it is possible to adjust the brakes by means of the back rods without getting under the chassis. All that it is necessary to do is to loosen the front two nuts, then, if it be necessary to slack off the. shoes slightly, turn these nuts forward and tighten up those at the back of the new double eyes. The reverse holds. 'good for tightening the brake shoes on to the drums.

The brakes can also be adjusted in the way common to A.E.O. vehicles, i.e. by slacking back the nuts and turning the centre hexagon to the right or to-the left according to requirements. The long double eyes were drilled out and tapped . in. Whit. thread, whilst the front double eyes and old rods were discarded and new shaped double eyes were forged and drilled as shown. The holes for the rods were drilled and bushed with brass, giving a fin, clearance hole. The idea of the bush is to avoid vibration damaging the threads if the rods ever slack off. The rods themselves areforgings, one end being screwed in. "Whit.,

and the other in. Whit.. The hexagon in the centre is I in. bolt head size and is solid•with the rod. Nothing is disturbed beyond removing the old rods and coupling up in the usual way.

It is necessary to plane a slot in each of the double eyes in order to provide clearance for the bolt heads when the brakes are actuated.