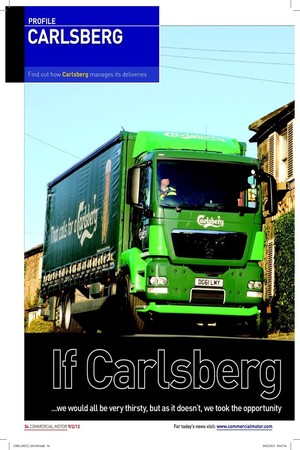

CARLSBERG

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

Find out how Carlsberg manages its deliveries

...we would all be very thirsty, but as it doesn’t, we took the opportunity

to talk to national fleet engineer Andrew Davis and his team Words: Will Shiers With a 25% growth in its drinks logistics operations over the past year, several new contracts to service and a leet in excess of 320 vehicles, national leet engineer Andrew Davis and the rest of the 10-strong senior logistics team at Carlsberg UK face plenty of challenges.

Perhaps the greatest of these is to ensure that it speciies exactly the right vehicles for the right jobs, which is something that they take incredibly seriously. So much so that some of the latest batch of 55 new MANs to join the leet have been custom-built in Munich speciically to Carlsberg’s exact speciications.

“We are the last major brewer in the country to manage the distribution of our own brand, so getting the right vehicles, and the right mix of vehicles, is very important to us,” explains Carlsberg UK logistics director Mark Groves.

City drays

The lightest vehicles on Carlsberg UK’s leet are 15 Isuzu NQR 7.5-tonners, all itted with Lawrence David specialist curtainsider bodywork.

These city drays (as the company refers to them) are perfectly suited to delivering to pubs, clubs and hotels in congested urban areas, and are vastly more suitable than the 3.5-tonne Mercedes-Benz Sprinter vans they replaced. “Although they have the same footprint as a van, the payload is 3,600kg compared with 1,200kg,” explains Davis. Also, thanks to their purpose-built dray bodywork, they can cope with heavy barrels being dropped from loading bays. This is something that, with time, totally destroys the cargo loor of a panel van. Fraikin supplied the Isuzus, and Carlsberg’s existing contractors maintain them on-site. They will remain on the leet for ive years.

Urban Artics

Moving up in size, urban artics play a key role in the leet, with 143 of them spread across the brewer’s four UK RDCs and 11 smaller depots.

Carlsberg’s irst urban artics were MAN TGLs. They started out as rigids, but were converted to tractor units in the UK by Wheelbase Engineering. However, the latest batch of 14 TGMs were purpose-built in Germany to Carlsberg’s exact speciications. The 290hp tractors feature a deep day cab (giving the crew room to store their wet gear) and TipMatic automated manual transmissions. The ride height is 1160mm, but this can be lowered to 1030mm for deliveries. They are plated at 26 tonnes, giving a potential payload of 10,500kg. More payload can be carried if palletised but 80% of deliveries are shop-loaded, which takes up more deck space, explains Davis.

Although Davis has calculated that urban artics are 8.7% more costly to buy and operate than rigids, he says that for some urban environments (like London) they are “the only viable option” . He explains that their manoeuvrability means drivers can often re-route in order to avoid congestion, helping Carlsberg maintain its 98% on-time/in-full delivery performance. They were supplied by the MAN dealership in Northampton, and are maintained on-site by the manufacturer’s dealers.

Rigids

But Davis describes its rigid drays as the “workhorse” of the leet, and says their numbers will increase as they replace some of the older urban artics. “In fact, we only really stray away from these when there are operational requirements that they cannot meet,” he says. Their main advantage is low running costs; at least less than the urban artics anyway. He explains that they have improved residual values, lower R&Ms and are better on fuel economy too. It has recently added 34 new 320hp MAN TGS 26-tonners with Palletliner curtainsider bodies to service new contract wins. They have been acquired through MAN Financial Services on a ive-year operating lease package with full R&M.

Drawbars

Carlsberg’s leet of drawbars consists of three-axle MAN TGS prime movers and purpose-built compact 5m trailers. Flexibility and payload are key to their use, and the combination is capable of carrying up to 15-tonne loads on long-haul delivery routes where a return to base for a second delivery simply isn’t possible.

The loads on these vehicles are non-palletised, covering the more tailored consignments of individual barrels, cases of drinks and so on. These are all hand-loaded through the rear of the vehicle, before being ofloaded through the curtain-sides at the inal point of delivery by the two-man teams. As Davis explains: “If we tried to palletise these deliveries, we would simply lose too much space on the truck. We are dealing with around 2,000 different SKUs [stock keeper units] and an average of up to 18 drops a day for each truck.” On certain routes, where the return follows the outbound journey, the trailers, once empty, are often left in a customer’s car park for later collection, further improving economy and manoeuvrability. If needed, they can also work with standard length drawbar trailers without loss of performance.

Metroliner

Perhaps the most unusual truck on the leet is the MetroLiner, which is the name Carlsberg has devised for a regular 6x2 tractor (which is used for trunking at night) coupled to an urban artic trailer (for dray operations in the day). While it’s not as manoeuvrable as an urban artic, Davis says it will go everywhere a 26-tonne rigid will go, and not surprisingly, with 430hp on-tap, “the drivers love it”.

The ifth wheel has been lowered and a slimline neck on the trailer means it rides at 90mm instead of 120mm – giving it the same deck height as a rigid.

Davis estimates that this combination could eventually be used on 10% of Carlsberg’s routes, saving £30,000 for every urban artic it replaces.

PROJECT TORCH

Carlsberg is working on its Olympics strategy (Project Torch), and is evaluating whether night-time deliveries will be necessary. If it does go down this route, then rubber mats will be a necessity. “We already specify the quietest electric motors on taillifts anyway,” says Davis.

While Carlsberg doesn’t envision the Olympic routes being a problem, its main concern is how strict the London boroughs’ parking restrictions will be. For more information on the Olympics, go to summerfreightplanning.co.uk

Back to back

For a truck maker to have any chance of selling into the Carlsberg leet, it must embrace the irm’s in-house maintenance programme – in other words, it must be willing to use the independent contractors Carlsberg retains in its own depots for repair and routine maintenance, but still take care of parts supply and all warranty and driveline work. “It’s what I call a ‘back-toback’ system,” explains Davis. “Ourselves, our contractors and our local dealer work in a common direction at each of our depots. It means we have lexibility to deliver speed of repair when needed, but retain the all-important backing of the manufacturer on other key elements.” Davis says MAN has already impressed in this area, and that this played a key role in the company’s recent decision to invest £4.5m in a leet extension with the marque. He gives the example of Aquila Trucks, which runs the workshop at its Gravelly Hill, Birmingham depot, where 63 trucks are currently based. It’s open from 6am to 10pm every day, and MAN Mobile 24 is called on for out-of-hours work.

Although all minor maintenance, servicing and accident repairs are done on-site (where there is a good stock of fast-moving spare parts), larger jobs and major accident repairs are carried out at Aquila Trucks’ own workshop.

Aquila even ensures that the AdBlue tanks are topped-up since Carlsberg insisted that it was incorporated into the R&M package.

Davis praises workshop manager Andy Iredale from Aquila Trucks, who he says acts more like the Carlsberg depot leet engineer, and knows the operations requirements very well. “We value the people who support our logistics operations more than the badge on the front of the trucks,” he adds.

A long life

While Carlsberg has taken the latest batch of MANs on ive-year contracts, Davis says they plan to run them for eight years. “After ive years, the dealer will buy them back off the lease company and we will buy them off the dealer,” he explains, “I call it smoke and mirrors.” But although the company always runs its trucks for eight years (city drays being the only exception), they do get a mid-life makeover.

Trailers are kept for longer, and are refurbished at eight years. Don-Bur, which carries out the work, makes numerous improvements, including shot blasting the chassis, retroitting Knorr Bremse EBS, replacing the curtains and itting new marker lights. It also adds conspicuity markings, despite not legally having to.

Driver training

In addition to vehicle selection, another thing Carlsberg takes incredibly seriously is training. All drivers have undergone SAFED training, which counts as one of their ive Driver CPC modules.

Rather than run the risk of these newly learned skills being forgotten, Carlsberg drivers are continually monitored through Microlise telematics (which has been itted to the entire leet). It records data on numerous aspects of driver behaviour, including idling, gear changes, harsh braking, over-revving, speeding and driving in the green band. Drivers receive an A to G rating, and the names of the ive best and worst performers are seen by the Carlsberg transport manager each week.

It holds a driver of the year competition, with the

THE OPERATION

Alongside its own brand beers, including Carlsberg, Carlsberg Export, Tuborg, Tetley’s, San Miguel, and Staropramen, Carlsberg UK also sources, stocks, picks and delivers a massive selection of wines, spirits, beers and other products for customers. It is a huge wholesaling activity, and between 50% to 60% of what it carries are other peoples’ brands.

This highly sophisticated operation is directed only to on-trade customers, namely pubs, clubs, restaurants and hotels. Off-trade customers such as supermarkets, shops and off-licences are managed separately.

It has distribution contracts for pub groups – like Greene King, Admiral and JD Wetherspoon’s – and its main logistics competitors are Tradeteam and K&N Drinks Logistics.

winner receiving a cash prize and trophy.

Davis says the scheme has been a complete success, and as well as reducing accident rates, Carlsberg’s fuel bill has been slashed. In a single four-week period, 45,251 litres of fuel were saved, representing a saving of £50,000 (and 122.61 tonnes of CO2).

“SAFED gets them to the desired standard, and Microlise keeps them at it,” says Davis. “And the best bit is that I know there is still room for improvement.” ■