Bodging won't fo4 the DTp examine

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

...says Noel Villier, who has been to the Yeadi testing centre to see the men from the Minis checking public service vehicl

VEHICLE maintenance standards have improved since the advent of annual testing and are now generally good. Russell Gosling, station manager of the Department of Transport heavy goods vehicle testing station at Yeading, Middlesex, told me.

Most hgv operators generally prepare their vehicles well and maintain a high safety standard. Brake faults are, however, still among the commonest found at test stations. This is sometimes because roller test equipment at the station shows up the efficiency of each individual brake, whereas often the operator, who relies on a Tapley meter, is only able to check the overall efficiency.

Faults in brake pipes are common and fuel and oil leaks are found in many vehicles. Obvious faults such as cracked mirrors and faulty lights and legal plate details are now comparatively rare, Mr Gosling told me.

Serious exceptions are sometimes seen at the station. Our examiner showed me the head of a nut that once secured part of the steering box on a Ford Transit. The nut had obviously been overtightened and had snapped off. The vehicle owner had replaced it by sticking it on with an adhesive such as Araldite. His deception did not, however, fool the sharp-eyed vehicle examiner.

Ice-cream vans often are over 30cwt unladen and must have an annual test at hgv testing stations. Many of these vehicles' owners seem not to be as aware of their vehicle's maintenance needs as they might be and often have to bring their vehicles back for a retest. Steering and suspension faults are particularly common on icecream vans with independent front suspension. One of the vehicle examiners told me that he felt that these vans were often overbodied and were just not up to the job.

Most vehicles presented at the station were generally in a clean condition underneath, which is very important and helps the examiner in his task. The examiners do, however, exercise a great deal of discretion when weather conditions are bad, when high-pressure steam cleaning equipment is likely to be frozen up.

Large operators and many bigger own-account operators have excellent maintenance systems and facilities but often are only as good as their staff. On most occasions they leave little .room for criticism but

occasionally the good name of their employers is let down.

The small operator who does his own maintenance too generally does a good job.

Those that rely on outside garages and main dealers often face high repair bills when their vehicles are prepared for tests. On many occasions, I was told, examiners are surprised by the number of parts that are brandnew on privately owned vehicles.

Examiners often suspect that items have been replaced unnecessarily. If this is not the case, the vehicle's condition before it was made ready does not bear thinking about.

One worrying factor reported by the examiners is drivers often do not know of all the controls on their vehicles. Often they receive blank looks when they ask drivers to apply the secondary brake and other safety devices, One examiner I spoke to at Yeading told me that they still, despite ample publicity, find vehicles with mixed radial and cross-ply tyres on the same axle, which is particularly worrying.

Psv vehicles often visit the test centre for re-certification and annual inspection and I am glad to report that Mr Gosling told me that they are generally prepared to a high standard. A little better, if anything, than road haulage vehicles.

Royalty are not exempt from vehicle test requirements and their horse-boxes have to make an annual visit to Yeading. Their maintenance predictably is to a high standard.

In general, the picture this year seems favourable. The annual testing of heavy goods vehicles which began in 1968 has undoubtedly raised the standards of the British road transport industry — yet figures published by the Department of Transport show that in the 11 traffic areas of England. Scotland and Wales, 20 per ce—nt.Of vehicles stopped in random spot checks in 1977 received either immediate or delayed prohibition notices.

Of vehicles inspected at operators' premises, predictably only 6 per cent received prohibition notices, and of vehicles inspected at test stations, 15 per cent were prohibited.

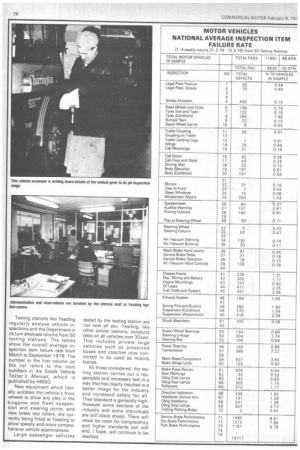

The somewhat lower figure for vehicles inspected at opera tors' premises shows that if the premises are suitable for inspections, it is likely that the particular operator has above average maintenance facilities. Testing stations like Yeading regularly analyse vehicle inspections and the Department in its turn analyses returns from 50 testing stations. The tables show the overall average inspection item failure rate from March to September 1978. The number in the first column on the list refers to the item numbers in the Goods Vehicle Tester's Manual, which is published by HMSO.

New equipment which literally wobbles the vehicle's front wheels to show any play in the kingpins and front suspension and steering joints, and new brake test rollers, are currently being fitted at Yeading to allow speedy and more comprehensive vehicle examinations.

Large passenger vehicles tested by the testing station are not now all psv. Yeading, like other similar stations, conducts tests on all vehicles over 30cwt. This includes private large vehicles such as preserved buses and coaches now converted to be used as mobile homes.

All those considered, the testing station carries out a. responsible and necessary test in a way that has clearly resulted in a better image for the industry and increased safety for all. Their standard is generally high. However some sections of the industry and some individuals are still black sheep. There will never be room for complacency and higher standards can still and, I hope, will continue to be reached.