Distinctive Designs of Six-wheeler Conversion

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

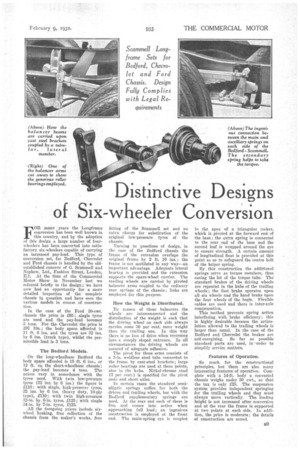

FOR ,many years the Longframe conversion has been well known in this country, and by the adoption of this design a large number of fourwheelers has been converted into satisfactory six-wheelers capable of carrying an increased pay-load. This type of conversion set, for Bedford, Chevrolet and Ford chassis is handled by the oldestablished concern of G. Scarainell and Nephew, Ltd., Fashion Street, London, E.1. At the time of the Commercial Motor Show in November last we referred briefly to the design; we have now had an opportunity for a more detailed inspection of the complete chassis in question and have seen the various models in course of construction.

In the case of the Ford 30-cwt. chassis the price is £95; single tyres are used and the pay-load becomes 3 tons. For the Chevrolet the price is 197 10s.; the body space afforded is 31 ft. 6 ins, and the tyres are 32 ins. by 6 ins. (truck type), whilst the permissible load is 3 tons.

The Bedford Models.

On the long-wheelbase Bedford the body space afforded is 15 ft. 6 ins., or 12 ft. on the short-wheelbase chassis; the pay-load becomes 4 tons. The Prices vary in accordance with the tyres used. With twin low-pressure tyres (32 ins, by 6 ins.) the figure is 1110; with single, high-pressure tyres,

32 ins. by 6 ins. (heavy duty, 10-ply type), £110; with twin high-pressure 82-in. by. 6-in. tyros, £125; with single 34-in. by 7-in. tyres, 1125.

All the foregoing prices include sixwheel braking, free collection of the chassis from the maker's works, free fitting of the Scammell set and no extra charge for substitution of the original low-pressure tyres of the chassis.

Turning to questions of design, in the case of the Bedford chassis the frame of the extension overlaps the original frame by 2 ft. 10 ins.; the frame is not mutilated in any way—an important advantage. Adequate lateral bracing is provided and the extension supports the spare-wheel carrier. The trailing wheels are carried by pivoted balancer arms coupled to the ordinary rear springs of the chassis; links are employed for this purpose.

How the Weight is Distributed.

By reason of these balancers the wheels are interconnected and the distribution of the weight is such that the driving wheel on each side always carries some 30 per cent, more weight than the trailing one. In this way there is no loss of drive when reversing into a steeply sloped entrance. In all circumstances the. driving wheels are assured of adequate adhesion.

The pivot for these arms consists of a 3-in. weldless steel tube connected to the frame by cast-steel brackets; large roller bearings are used at these points, also in the hubs. Nickel-chrome steel (3 per cent.) is specified for the pivot ends and short axles.

In certain cases the standard semielliptic springs suffice for both the driven and trailing wheels, but with the Bedford supplementary springs are used. At the rear end each of these is free and comes into action when approaching full load ; an ingenious construction is employed at the front end. The main-spring eye is coupled to the apex of a triangular rocker, which is pivoted It the forward end of the base; the extra spring is connected to the rear end of the base and the second leaf is wrapped around the eye to ensure strength. A certain amount of longitudinal float is provided at this point so as to safeguard the centre bolt of the helper spring.

By this construction the additional springs serve as torque members,. thus easing the lot of the torque tube. The standard brakes of the driving wheels are repeated in the hubs of the trailing wheels ; the foot brake operates upon all six wheels and the hand brake upon the four wheels of the bogie. Flexible cables are used and there is inter-axle compensation.

This method prevents spring action interfering with brake efficiency ; this is highly desirable .because the articulation allowed to the trailing wheels is larger than usual. In the case of the Bedford and Chevrolet the brakes are self-energizing. So far as possible standard parts are used, in order to simplify service matters.

Features of Operation.

So much for the constructional principles, but there are also many interesting features of operation. Complete with a 14-ft. bodY a converted chassis weighs under 50 cwt., so that the tax is only 125. The suspension system provides independent springing for the trailing wheels and they must always move vertically. The loading height is not increased after conversion and at the rear the frame is supported at two paints at each side. In addition, the price is moderate; the details of construction are sound.