HOW THE SIX-WHEELER IS PROGRESSING.

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

World-wide Activities. Outstanding Examples of British, American, French and German Design. Multi-wheeler Advantages.

MHROUGEOTJT the world the great est interest is being taken in the development of the rigid-framed vehicle with more than four wheels, and there has undoubtedly been considerable progress in many quarters. Whilst new types are being brought out in increasing numbers, some of those already existing have long passed the experimental stage, and have already proved their worth in actual service.

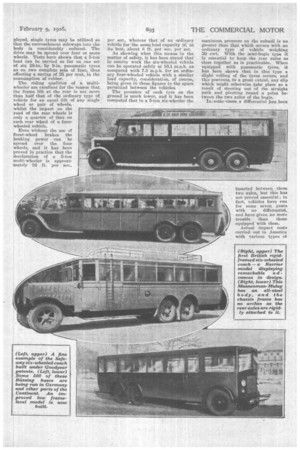

In the United States buses and coaches with six and even eight wheels are being used in large numbers, and with double-deck bodies the fact that the load, is distributed over four wheels at the rear renders the employment of pneumatic tyres a much safer proposition, as the rapid deflation of one tyre does not affect the relative position of the vehicle to other than an unappreciable extent. Amongst the vehicles which are proving popular are the Safeway, built under Goodyear patents ; the Versare, which has eight wheels and a Tietrol-electric transmission ; the Mack, which has two propeller shafts, each driven from the gearbox; and the Gotfredson, also built under Goodyear patents, and embodying such improve

meats as swivelling spring ends which relieve the springs of torsional stresses.

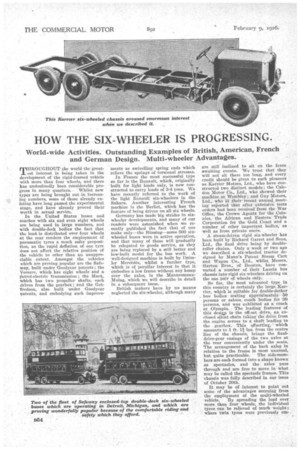

In France the most successful type so far is the Renault, which, originally built for light loads only, is now constructed to carry loads of 3-4 tons. We have recently referred to the work of the light Renault six-wheelers in the Sahara. Another interesting French machine is the Berliet, which has the feature of being driven on all six wheels.

Germany has made big strides in sixwheeler developments, and many of our readers were astonished when we recently pablished the fact that of one make only—the Bussing—some 500 sixwheeled buses were in active operation, and that many of these will gradually be relegated to goods service, as they are being replaced by a still better and low-built model for the bus work. A well-designed machine is built by Dalailer Merc6des, whilst a further type, which is of peculiar interest in that it embodies a low frame without any hump over the axles, is the MannesmannMulag, which we will describe in detail in a subsequent issue.

British makers have by no means neglected the six-wheeler, although many

are still inclined to sit on the fence awaiting events. We trust that they will not sit there too long, and every credit should be given ta such pioneers as Karrier Motors, Ltd. who have constructed two distinct models; the Caledon Motor Co., Ltd., who showed their machine at Wembley ; and Guy Motors, Ltd., who at their'recent annual meeting rePorted that after extensive tests orders had been received from the War Office, the Crown Agents for the Colonies, the African and Eastern Trade Corporation for the Gold Coast and a number of other important bodies, as well as from private users.

A steam-driven rigid six-wheeler has been built by Richard Garret and Sons, Ltd., file final drive being by doubleroller chains. Only a week or two ago we described a six-wheeled tractor designed by Mann's Patent Steam Cart

and Wagon td., whilst Messrs. Barton Bros., Co.,Of• Beeston, have converted a' number of their Lancia bus chassis into: rigid six-wheelers driving on the one pair of wheels only: So far, the most advanced type in this country is certainly the large.KarTier, which is suitable for double-deeker bus beaks seating approximately 50 persons or, saloon coach -bodies for 30 persons, arid was exhibited as a clinch at Olympia. The leading features of this design is the off-set •drive, an. enclosed silent chain taking the drive from the engine across to a shaft leading to the gearbox.. This offsetting, • which amounts to 1 ft. n ins, from the centre line of the chassis, brings the finaldrive-gear casings of the two axles at the rear conveniently under the seats. The arrangement of the back axles in relation to the frame is most unusual, but quite practicable. The side-members are each formed into a shape known as spectacles, and the axles pass through and are free to move in what may be called the spectacle frames. This chassis was fully described in our issue of October 20th.

It may he of interest to point out someof the advantages accruing from the empleyment of the multi-wheeled

vehicle. By spreading the load over more than four wheels, the individual tyres. can be relieved of much weight ; where twin tyres were previously em ployed, single tyres may be utilized so that the encroachment sideways into the body is considerably reduced. The drive may be spread over four or more wheels. Tests have shown that a 5-ton load can be carried as far on one set of six 38-in. by 9-in, pneumatic tyres as on two complete sets of four, thus effecting a saying of 25 per cent. in the consumption of rubber.

The riding qualities of a multiwheeler are excellent for the reaton that the frame lift at the rear is not more than half that of the ordinary type of vehicle for an equal lift of any single wheel or pair of wheels, whilst the impact on the road of the rear wheels is only a quarter of that on each rear wheel of a fourwheeled vehicle.

Even without the use of front-wheel brakes the braking power can be spread over the four wheels, and it has been proved in practice that the deceleration of a 5-ton multi-wheeler is approxi-mately 16 ft. per sec.. per sec., whereas that of an ordinary Vehicle for the same4load capacity ig; at its best, about S ft. per sec. per sec.

As showing what this means in the matter of safety, it has been stated that in convoy work the six-wheeled vehicle can be operated safely at 16.1 m.p.h. as compared with 7.3 m.p.h. for an ordinary four-wheeled vehicle with a similar load capacity, consideration, of course, being given in these figures to the space permitted between the vehicles.

The pressure of each tyre on the ground is much lower, and it has been computed that in a 5-ton six-wheeler the maximum pressure on the subsoil is no greater than that which occurs with an ordinary type of vehicle weighing 30 cwt. With the semi-bogie type it is essential to keep the rear axles as close together as is practicable. When equipped with pneumatic tyres, it has been shown that in this type a slight rolling of the tyres occurs, and this prevents, to a great extent, any slip which might otherwise take place as a result of steering out of the straight path and pivoting round a point between the two axles of the bogie.

In,sonie,cases.a differential has _been

inserted between these two axles, but this has not proved essential; in fact, vehicles have run for some seven years with no differential, and have given no more trouble than those equipped with them. Actual impact tests carried out in America with various types of vehicle have shown that the impact between wheel and road on a 5-ton sixwheeler is slightly under that of an ordinary pattern 2-tonner equipped with pneumatic tyres. The figure at an average speed of 174m.p.h. proved to be 7,000 lb. for the six-wheeler and 11,500 lb. for a, 5-tonner on pneumatics, or 29,000 lb. for a vehicle of similar capacity on solid tyres. The impact value may be as high as seven .times the_ static load on a wheel fitted with a solid, tyre when striking a projection only 1 in. high, and approximately double the static load where pneumatic tyres are employed.

' It is an undoubted fact that one of the greatest causes of tyre wear, whether the equipment be solid or pneumatic, is wheelspin, which occurs through the wheels lifting clear of the :-Vsad surface, and being suddenly braked and consequently abraded by the road when they again come into centact with it. This spin is practically eliminated

in the case of a multi-wheeler driving on the four rear wheels, for it is almost inconceivable that two wheels at one side could be off the ground at the same time. This is prevented by the interconnection of the rear springs in some models or the use of single semi-elliptic springs, fulcrumed at their centres, in others. In either design the lifting of one wheel puts increased pressure through the. spring., on the . correspond-. jug wheel of the other axle, thus tending to Mid it down to the road surface.' -.^There have been criticisms of the semi-bogie type of vehicle, some of the critics arguing that, owing to the twist.; ing action of the bogie under load, it is possible that one pair of wheels may take all the drive ; but, in practice, such effect has proved to be unimportant.

It may be that for extremely rough cross-country work it will be preferable to take the thrust from each axle independently, and the British War Department has recently issued specifications of two such chassis for moderately light loads. The types recommended each embody a serai-bogie, but additional rods for taking the torque reaction are mounted between each worm casing and the cross-member which forms a fulcrum for the semi-elliptic springs. Both the torque rods and the springs are specially mounted, so that no twist occurs on them when one axle is in a different plane from the other, this beingeffected by the provision of ball joints in the case of the rods, and spherical seatings for the springs. In some other chassis, such, for instance, as the Biissing, each axle has a torque tube ending in a spherical mounting on the frame, so that the torque and the push of the drive are taken independently to the frame. However, the proof of the pudding is in the eating thereof, and we have personally tested a Kanier sixwheeler over the roughest possible ground without any difficulties being experienced.