TENDENCIES IN PAS ER CHASSIS DESIGN.

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

The Influence of the Ministry of Trans' Goods Chassis. High-efficiency Power wheel Brakes and Low-frarr•

mimendations. The Divergence from the ilent and Accessible Back Axles, Four; the Leading Characteristics:

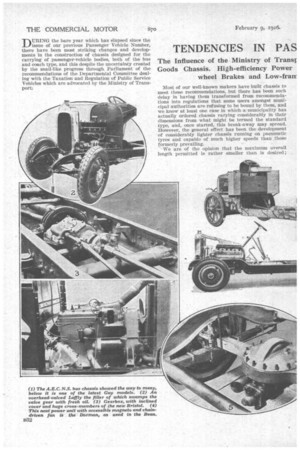

DRING the bare year which has elapsed since the issue of our previous Passenger Vehicle Number, there have been most striking changes and developments in the construction of chassis designed for the carrying of passenger-vehicle bodies, both of the bus and coach type, and this despite the uncertainty created by the snail-like progress through Parliament of the recommendations of the Departmental Committee dealing with the Taxation and Regulation of Public Service Vehicles which are advocated by the Ministry of Transport

Most of our well-known makers have built chassis to meet these recommendations, but there has been such delay in having them transformed from recommendations into regulations that some users amongst municipal authorities are refusing to be bound by them, and we know at least one case in which a municipality has actually ordered chassis varying considerably in their dimensions from what might be termed the standard type, and, once started, this break-away may spread. However, the general effect has been the development of considerably lighter chassis running on pneumatic tyres and capable of much higher speeds than those formerly prevailing.

We are of the opinion that the maximum overall length permitted is rather smaller than is desired; another 18 ins, would make a big difference from many points of view.

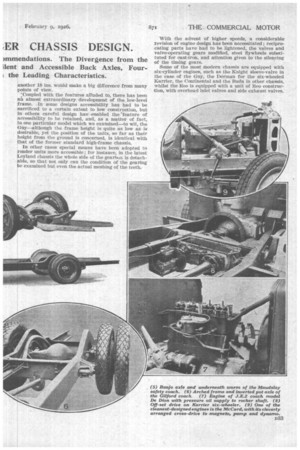

'Coupled with the features alluded to, there has been an almost extraordinary development of the low-level frame. In some designs accessibility has had to be sacrificed to a certain extent to low construction, but in others careful design has enabled the 'feature of accessibility to be retained, and, as a matter of fact, in one particular model which we examined—to wit, the Guy—although the frame height is quite as low as is desirable, yet the position of the units, so far as their height from the ground is concerned, is identical with that of the former standard high-frame chassis.

In other cases special means have been adopted to render units more accessible; for instance, in the latest Leyland chassis the whole side of the gearbox is detachable, so that not only can the condition of the gearing be examined but even the actual meshing of the teeth. With the advent of higher speeds, a considerable revision of engine design has been necessitated ; reciprocating parts have had to be lightened, the valves and valve-operating gears modified, steel flywheels substituted for cast-iron, and attention given to the silencing of the timing gears.

Some of the most modern chassis are equipped with six-cylinder engines, such as the Knight sleeve-valve in the case of the Guy, the Dorman for the six-wheeled Karrier, the Continental and the Buda in other chassis, whilst the Reo is equipped with a unit of Reo construction, with overhead inlet valves and side exhaust valves. The remarkable Vulcan safety coach, one of the Fiats, and, of course, the Halley, are also in the six-cylinder class.

Overhead valves are becoming increasingly popular.

• An excellent example is the latest Leyland power unit, which ticks over without the slightest vibration or noise. Other examples are to be found in the Saurer and Berliet. The overhead camshaft is, of course, retained In the Maudslay safety coach, and this situation is also employed for the camshaft on the M. and D. Somewhat unusual construction of the valve-operating gear is to be found in one of the new Halley chassis, as the camshaftis carried in an oilbath behind the tappet

• cover, where it is immediately accessible.

A recent addition to the cooling system of several engittes is the thermostat, and, in our opinion, the fitting of a reliable instrument of this type is a real improvement.

Radiators are mainly of the built-up type, but in order to improve their appearance several are equipped with one-piece outer shells.

Increased speed has necessitated the overhauling of many systems of lubrication, and there has been. a general increase in the size and accessibility of the filters. External and internal piping has been dispensed with so far as possible, channels being provided in the crankcase. Complete pressure feed or pressure feed combined with troughs is usually found. Not very long ago timing gears and chains received their lubricant more by luck than judgment, but now an ample • supply is assured, in inost cases the oil flowing over the timing mechanism from the top. In the new McCurd oil is always retained by special reservoirs, so that immediately the engine starts oil flows over the timing gears.

Clutch design is still in, a state of fluidity. There is a tendency towards the single plate, consisting either of fabric friction rings secured to the flywheel and a pressure plate and acting on a steel disc, as in the Bristol and several other chassis, or friction rings secured to the steel disc and pressed into contact between the flywheel and a pressure plate, as in the Leyland. We must not forget that the' Albion Company were pioneers in this connection, and such clutches have for long been employed on the Halley • they are also being used on several of the Guy Models, the W. and G., M. and D., Gotfredson, etc. Provision is made, in some eases, for adjusting the clutch springs, but, in the opinion of certain designers, such adjustment is unnecessary, and has, therefore, not been adopted.

Unit construction of engine and gearbox, except for the lighter models, does not appear to be so popular as formerly. The trend is towards mounting the engine and gearbox either separately, each being three-pointsuspended, or together on a three-point-suspended subframe. The latter method appears to afford the minimum risk of distortion.

Much use is being made of fahric joints on the clutch shaft, for they not only permit a certain amount of

movement endwise, but, being seldom out of alignment to any more than a very slight degree. have an exceed, ingly long life. There is another point also, which is not alwaysrealized, and that is that they absorb minor engine vibrations.

Higher transmission speeds and considerable space between gearbox and rear axle, as found in many passenger models, have necessitated the employment of two and even three-piece propeller shafts provided with a centre bearing and three universal joints. The shafts consist usually of large-diameter tubes. In one chassis, the latest passenger Lancia, the shaft consists of several sections bolted together, each section being a forging accurately bored and balanced. In the Garner chassis, the propeller shaft is in three sections, the centre one of which can slide in its bearings.

Where fabric joints are employed in the propeller shaft it has proved advisable to centre these to relieve the fabric from shaft weight and centrifugal stresses. . This is done, for instance, in the Halley and the Vulcan. In any case, every endeavour is being made to obtain as straight a drive from engine to axle as is possible and, where the design prevents this, mechanical joints of large size and well lubricated are employed. The questions on which type of axle is the best and how the final drive should be effected are somewhat difficult to answer. The worm in the Pot casing, and either mounted above or below the axle, still appears to be the most popular. In some cases the pot is replaced by a horizontal banjo, and this certainly provides an excellent measure of accessibility both above and below the casing. For heavy loads and where much hill-climbing may have to be done at comparatively low speeds, the double-reduction axle is perhaps better than the worm, and we have been assured by one manufacturer who uses both types that. in such circumstances, the double-reduction is almost a gear better, whereas there is practically no difference at higher speeds and on the level. A most advanced type of double-reduction axle is that used on the Leyland ; this has a spiral-bevel first reduction and a doublehelical second reduction. In the Saurer a single-reduction straight bevel gear giving a large ratio is employed and careful design and manufacture have rendered this most efficient.

Brakes are, of course, a subject of vital importance. We are of the opinion that the majority of passenger chassis should have brakes acting on all four wheels, and for anything over 2-ton load capacity a servo device should be • incorporated. In the Mauclslay the

front-wheel brakes are operated by the rocking of the transmission brake-shoe fulcrum, and a similar method is employed in the Leyland, whilst the Guy has PerrotBendix three-shoe front brakes, in which one shoe provides a servo effect.

With the advent of four-wheel brakes there has been an increase in the number of brakes acting direct on

the transmission, but some makers give optional equipment of two brakes on the rear wheels, or one brake on the rear wheels and one on the transmission. One of the servo devices whieh has been found most efficient is the Dewandre, as used On the Guy and Vulcan. This has the advantage that in the unlikely event of the vacuum failing for any reason, the driver can still apply the brakes by manual effort. Attention has also been given to the Rubury-Alford and Alder pattern, which presents the advantage of a positive release of the outer wheel when cornering, and, in its latest form, also releases the corresponding rear wheel. The Siturer engine brake is an excellent example of an uncommon type which gives adequate braking power for long, easy gradients, with no expenditure on friction materials.

Frames have, of course, altered greatly. At one time a straight frame was considered to be the ideal, but with the decrease in the frame height it is necessary, in the majority of cases, to drop the frame in the region of the dash and to hump it over the rear axle, dropping it again," sometimes to a still lower level, behind' the axle. Careful proportioning of the size of the side " members according to the stresses involved, ample crossstaying, and the employment of particularly strong cross-members have resulted in frames quite stiff, enough to prevent undue racking of the bodies.

Many of the low-frame chassis have underslung rear Springs. These present the advantage that the fore

and-aft movement of the axle resulting from spring deflection is not nearly so great as when the springs are mounted above it. Most chassis are also designed to maintain springs practically flat under load, and the average frame height with the vehicle loaded is in the neighbourhood of 2 ft.

There have not been very many developments in connection with wheels. These are usually of the caststeel spoked or the steel-disc variety. Taper-roller wheel bearings are being more generally used, but some makers find that with more careful lubrication there is little to choose between floating bushes and ball or roller bearings once a vehicle has got into motion.

Ease of maintenance is a subject which is receiving far more attention than formerly, but there is still much to be done before the maintenance engineer will be fully satisfied. It should not be necessary to disturb major units to obtain access to the clutch or to move the gearbox to drop the propeller shaft.

The general lubrication of the chassis has been greatly improved by the adoption of the greaSe-gun equipment. In seine chassis, such as the Guy, even more than this is done, oil reservoirs of ample capacity greatly simplifying the task of lubrication.

In connection with the development of the low-level frame every credit should be given to the Associated Equipment Co., Ltd., for their development of the N.S.-type bus chassis, with its interesting form of axle having underneath worm drive and final drive by spur pinions and gear rings. This chassis has certainly set the example to many.

Reverting to brake gear, one of the most interesting servo mechanisms for their operation Is that embodied in the low load-line Dennis. It consists of a clutch with two asbestos fabric facings, which is normally free and is constantly driven from the gearshaft. When the brake pedal is depressed themotion is communicated to a lever on the servo-motor spindle, beside which is a second lever with a rod running rearwards and operating tile rear-wheel brakes. The adjacent faces of the bosses of these two levers have inclined serrations which fit together; consequently, the first result of brake application is to carry both levers forward until the brake is on slightly, then the pedal lever overruns the other and, owing to the cam action of the serrations, operates the clutch. This drags round the servo-motor casing and results in applying thefront-wheel brakes, as well as increasing the power on those at tile rear.

One of the main features-of the servo device embodied in the Renault chassis is that the clutch-of the servo motor, which, incidentally, is driven from the gearbox, communicates with the operating gear through a short length of chain attached in such a manner that the servo effect is afforded whether the vehicle he running forward or backwards.

The Tilling-Stevens chassis, with its petrol-electric transmission, is particularly popular for use in hilly country, where constant gear-changing would have to be done with the ordinary gearbox; but, apart from this type, the makers have a new model known as the Express, which embodies an epicyclic gearbox.