1 :entrax-built US Stopmaster

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

'rakes will have high safety factor

J. P. Wilding, AM1MeehE. M1RTE, sts Rockwell-Standard system th novel actuation.

I-HEEL-BRAKE units to the design of V Rockwell-Standard, of America, are n to be put into production by Centrax trs Ltd., of Newton Abbot, Devon, who !ady make Rockwell-Standard axles ler licence. The brake units are called pmaster and will be offered for use in airke systems, although in America types hydraulic actuation are also available. Stopmaster design has been in existence over three years, during which time it is I that numerous improvements have been le.

Che most interesting feature of the Stott ;ter is that pressure is applied to both s of each brake shoe by dual wedge .iators, giving a two-leading-shoe action. :It actuator is operated by its own diaagm-type brake chamber which means I the main and secondary system requireits which are to be obligatory on British icles now can be met in a straightforward T. On a vehicle fitted with Stopmaster kes the diaphragms at the wheels can be independent circuits operated through a .1 foot-valve so that if there is a failure Ii brake will still be operating as leadingI-trailing units with half the brake effort. : is planned to offer four sizes of brake unit— n. by 4 in., 15 in. by 5 in., 15 in. by 6 in. and n. by 7 in. Brake lining areas are 126, 157, and 220 sq. in, respectively, and the distance

the centreline of the shoes to the mounting e location face can be one of six specified ensions. There are also alternative brake-nber sizes-9 sq. in. or 12 sq. in.—and the ge angle can be 10°. 12° or 14°.

'he brakes incorporate an automatic adjustit system and, if required. spring-brake iators can be supplied. On all the types offered red liners are fitted-0.75 in. thick at the re—which is a common American practice allows the liner to wear to an even thickness ire relining.

,utomatic adjustment of the brake shoes is )mplished by the use of a sleeve at the upper of one of the wedge plungers in each actuator these are connected to the plungers through fast helixes. The sleeves have ratchet teeth on their circumference which locate with plungers in the wedge-unit bodies. As the brake shoes are applied the sleeves on each side rotate and are held at the point giving correct lining-to-drum clearance.

While the main advantages with the Stopmaster design are compactness and the fact that the linings arc applied with an even pressure to the drums, there is also the important advantage when they are used to meet main and secondary system requirements that, in the event of a single failure, there is still braking at all wheels.

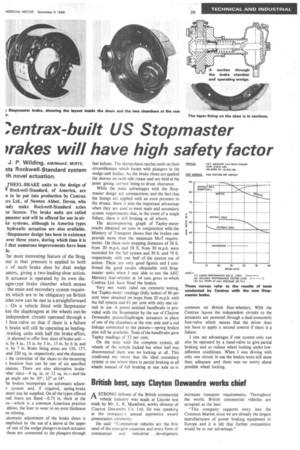

The accompanying graph of Tapley-meter results obtained on tests in conjunction with the Ministry of Transport shows that the brakes can provide more than the minimum MoT requirements. On these tests stopping distances of 26 ft. from 20 m.p.h. and 58 ft. from 30 m.p.h. were recorded for the full system and 30 ft. and 79 ft. respectively with one half of the system out of action. These are very good figures and I confirmed the good results obtainable with Stopmaster units when 1 was able to test the AEC Mercury four-wheeler at 14 tons gross to which Centrax Ltd. have fitted the brakes.

Very wet roads ruled out extensive testing, but Tapley-meter readings (fully laden) of 86 per cent were obtained on stops from 20 m.p.h. with the full system and 61 per cent with only one circuit in use. A power assisted handbrake is provided with the Stopmaster by the use of Clayton Dewandre piston/diaphragm actuators in place of one of the chambers at the rear axle and a rod linkage connected to the pistons—spring brakes also will be available. Tests of the handbrake gave Tapley readings of 32 per cent.

On the tests with the complete system, all wheels of the vehicle locked but when half was disconnected there was no locking at all. This confirmed my views that the ideal secondary system is one where there is partial braking at all wheels instead of full braking at one axle as is common on British four-wheelers. With the Centrax layout the independent circuits to the actuators are powered through a dual-concentric foot-valve which means that the driver does not have to apply a second control if there is a failure.

I can see advantages if one system only can also be operated by a hand-valve to give partial braking and so reduce wheel locking under !ow adhesion conditions. When I was driving with only one circuit in use the brakes were still more than adequate and there was no worry about possible wheel locking.