A Maintenance Scheme for Non-stop Transport

Page 56

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

A System Evolved for the Benefit of Agricultural Hauliers and Designed to Cut Vehicle Standing Time on Overhauls and Obviate Breakdowns

REGULAR readers of these articles will recall the name of Mr. F. T. Hosking, for I have on more than one occasion referred to correspondence and conversations I have had with him. Sometimes we have discussed the haulage of agricultural products, more often the subject has been maintenance of the ,vehicles engaged in such work.

Mr. Hosking, as may be gathered-from the foregoing, is a director of a company specializing in the merchandizing of agricultural products. He is also a member of the National Association of Corn and Agricultural Merchants. At the request of his Association, Mr. Hosking produced a booklet in whic4 his method of maintenance was fully described.

In an introduction to the booklet we are reminded of the Task System put into operation by the Army during the war, the purpose of which was the same as this maintenance scheme, namely, the prevention of breakdowns on the road.

This scheme is better adapted to the conditions of commercial operation. It is, moreover, tried and proved. Mr. Hosking; who runs 17 vehicles, has found that with little expense he can run his transport efficiently.

, The scheme needs reasonable workshop facilities, although It is suggested that simple routine washing and greasing of lorries should be done by drivers. It covers the full servicing of principals' and representatives' cars where all work is.done in the Workshop. In the particular scheme detailed in the booklet, full workshop facilities are available in a department of the business carrying out installation and maintenance of farm machinery and tractors. To deal with the number of vehicles concerned, it has been found in practice that onemechanic is fully employed when all the vehicles arc in good running order.

Methodical Inspection

The scheme can best be described as being a preventive maintenance system and entails the methodical inspection and repair of vehicles called in according to the rules in the vehicle 'instruction books. As the various services are carried out, the mechanic cannot help discovering those parts of the vehicle which show signs of wear and need to be replaced. By means of record sheets, transport managers can immediately set about obtaining replacement parts for fitting next time the vehicle comes in for service.

The aim of all maintenance work is to ensure that the vehicle concerned is off the road as little as possible for workshop attention. It is necessary to keep the work coming to the workshop in a steady flow each week. This is achieved by drawing up a list of vehicles and numbering each vehicle on the key. The key also indicates the registration number, whether the vehicle is private or Commercial, and whether the A service (see accompanying chart) is done by the driver or garage staff, and the average weekly mileage.

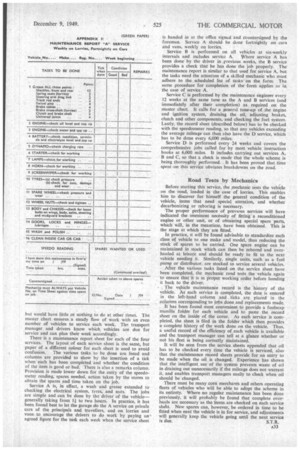

There are four types of service carried out at intervals of two weeks, six weeks, 12 weeks and 24 weeks. Allowing for four short weeks in the year, because of statutory holidays, there are two complete 24-week cycles, plus four slack weeks to catch up any arrears, making up the full 52 weeks in the year.

These services are described as A, B, C and D. and are described here. The master service chart can therefore he drawn up on a basis of 52 weeks. Taking vehicle No. 1 as an example, this comes in on week I for A, B. C and D services. In weeks 3 and 5 there is only the A service on this car, but in week 7 it has A and B services.

1322

it is easy to work out on the chart that not more than one vehicle has the D service each week, which is done to maintain a steady flow of work, as this service is comprehensive and takes time, Larger fleets of vehicles will, of course, need more mechanics, and the master chart can he worked out accordingly.

It should be noted that where service A is performed by the driver of the vehicle, no record has to be made on the master chart of dates for maintenance service. This chart is primarily the plan for the work of the maintenance engineer, and it is therefore unnecessary to record work to he performed, by drivers.

In the scheme under review,. the four services are given to the vehicle at an approximate average of 500, 1,500, 3,000 and 6,000 miles for the A, B, C and D services respectively. Some of the vehicles will be doing more than these distances and some less. If the vehicles were brought in for service on a mileage basis only, i.e., every 500 miles as the instrnedon book suggests, it would be found that in a mixed fleet the workshop would sometimes be inundated with work.

but would have little or nothing to do at other times. The master chart ensures a steady flow of work with an even number of vehicles to service each week. Th": transport manager and drivers know which. vehicles are due for 'service and can plan their week accordingly.

There is a maintenance report sheet for each of the four services. The layout of each service sheet is the same, but paper of a different colour for each sheet is used to avoid confusion. The various tasks to be done are listed and columns are provided to show by the insertion of a tick when each has been completed and whether the condition of the item is good or bad. There is also a remarks column. Provision is made lower down for the entry of the speedometer reading, spares needed, action taken by the stores to Obtain the spares and time taken on the job.

Service A is, in effect, a wash and grease extended to checking the electrical system. tyres, and nuts. The jobs are simple and can be done by the driver of the vehicle— generally taking from 14 to two hours. In practice, it has been found best to let the garage do the A service on private cars of the principals and travellers, and on lorries and vans to encourage the drivers to do work by paying an agreed figure for the task each week when the service sheet is handed in at the office signtd and countersigned by the foreman. Service A should be done fortnightly on cars and vans, weekly on lorries.

Service B is performed on all vehicles at six-weekly

intervals and includes service A. Where service A has been doneby the driver in previous weeks, the B service provides a check that he has done the job properly. The maintenance report is similar to that used for service A, but the tasks need the attention of a skilled mechanic who must adhere to the scheduled list of taskson the form. The same procedure for completion of the form applies as in the case of service A.

Service C is performed by the maintenance engineer every 12 weeks at the same time as the A and B services (and immediately after their completion) as required on the master chart. It calls for a general tune-up of, the engine and ignition system, draining the oil, adjusting brakes, clutch and other components, and checking the fuel system. Lastly, the record sheet (described below) has to be checked with the speedometer reading, so that any vehicles exceeding the average mileage can then also have the D service, which has to be done every 6,000 miles.

Service D is performed every 24 weeks and covers the comprehensive jobs called for by most vehicle instruction books at 6,000 miles. It includes. carrying out services A, B and C, so that a check is made that the whole scheme is being thoroughly performed. -It has been proved that time spent on this service obviates breakdowns on the road.

Road Tests by Mechanics ,

Before starting this service, the mechanic tests the vehicle on the road, loaded in the case of lorries. This enables him to discover for himself the general condition of the vehicle, items that need special attention, and whether decarbonizing or reboring is necessary.

The proper performance of previous services will have indicated the imminent necessity of fitting' a reconditioned engine or other unit, or of obtaining special spare parts, which. will, in the meantime, have been obtained. This is the stage at which they are fitted.

In practice, It will be found advisable to standardize each class of vehicle to one make and model,• thus reducing the stock of spares to be carried. One spare engine can be maintained in stock which can then be rebored and overhauled at leisure and should be ready to fit to the next' vehicle needing it. Similarly, single units, such as a fuel pump or distributor, are stocked to service several vehicles.

• After the. various tasks listed on the service sheet have been completed, the mechanic road tests the vehicle again to ensure that it is in proper working order before handing it back to the driver.

The vehicle maintenance record is the history of the vehicle. As each service is completed, the date is entered in the left-hand column and ticks are, placed in the ,colamns corresponding to jobs done.and replacements made. _ It has been found most convenient to provide a foolscap manilla folder for each vehicle and to paste the record sheet On the inside of the cover. As each service is completed, the sheet is filed in the folder which then provides acomplete history of the work done on the vehicle. Thus. a useful record of the efficiency of each vehicle is available and the transport manager can tell at a glance whether or not his fleet is being correctly Maintained.

It will be seen from the service, sheets appended that oil has to be checked every time the vehicle is serviced, also that the maintenance record sheets provide for an entry to be made when the oil is changed. Experience has shown that the intelligent use of the system prevents waste of oil in draining out unnecessarily if the mileage does not warrant it, and enables transport managers easily to check when oil should be changed.

There must be many corn merchants and others operating fleets of vehicles who will be able to adopt the scheme in its entirety. Where no regular maintenance has been done previously, it will probably be found that complete overhauls are necessary as the items are checked on each service shet.t. New spares can, however, be ordered in time to be fitted when next the vehicle is in for service, and adjustments will generally keep the vehicle going until the next service is due. S.T.R.