An Ingenio Load-lifting,

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

MACHINERYC RYING TRAILER

MODERN industrial conditions are such that large pieces of mechanism have often to be transported in an assembled condition, because the work of erection is in some instances most complicated and the pieces of plant are often consigned to destinations at which it would be impossible to build up any particular assembly from components. This means that large and heavy loads of great value must be carried under conditions which, in many cases, preclude the use of the railway, whilst the cost of conveyance by rail, where it be practicable, is often prohibitive.

Loading and unloading difficulties with such burdens are many and varied. One of the cleverest schemes which has been devised for handling these loads takes the form of a trailer, which has recently been produced by an engineering concern on the Continent.

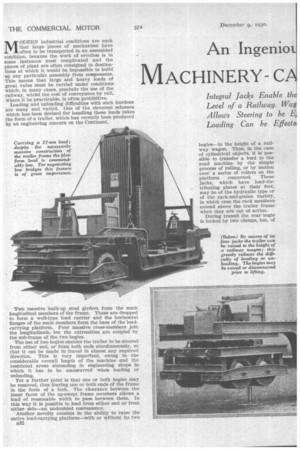

Two massive built-up steel girders form the main longitudinal members of the frame. These are dropped to form a well-type load carrier and the horizontal flanges of the main members form the base of the loadcarrying platform. Four massive cross-members join the longitudinals, but the extremities are coupled by the sub-frame of the two bogies.

The Ilse of two bogies enables the trailer to be steered from either end, or' from both ends simultaneously, so that it can be made to travel in almost any required direction. This is very important, owing to the considerable overall length of the machine and the restricted areas abounding in engineering shops in which it has to be manceuvred when loading or unloading.

Yet a further point is that one or both bogies may be removed, thus leaving one or both ends of the frame in the form of a fork. The clearance between the inner faces of the up-swept frame members allows a load of reasonable width to pass between them. In this way it is possible to load from either end or from either side—an undoubted convenience.

Another novelty consists in the ability to raise the entire load-carrying platform—with or without its two B32

bogies—to the height of a railway wagon. Thus, in the case of cylindrical objects, it is possible to transfer a load to the road machine by the simple process of rolling, or by motion over a series of rollers on the platform concerned. These jacks, which have load-distributing plates at• their feet, may be of the hydraulic type or of the rack-and-pinion variety, in which case the rack members extend above the trailer frame when they are out of action.

During transit the rear bogie is locked by two clamps, but, of course, the front one is free to carry out normal steering operations. There are 10 wheels, each with dual tyres. The wheels are mounted in pairs in pivoted subframes, which are controlled by enormous volute springs. The axles can thus oscillate so as to conform with road inequalities. Internal-expanding brakes are applied to each bogie and they are operated either from the steersman's seat or, if desired, by men walking alongside the machine.

One of the accompanying illustrations shows a 27-ton load mounted on one of these trailers.

On a recent journey the cost of transport represented only 80 per cent, of what would have had to be paid for railway transit. A vital point to remember in connection with the carriage of burdens of the class in question is that one loading and one unloading operation suffice. When rail transport is relied upon load transference is almost a sine qua non and costs, in consequence, are higher.

Only those who have had an experience of trailers or semi-trailers which can be steered from the rear end as well as from the front can appreciate what an enormous advantage this principle may be to the hanlier who has to enter restricted spaces with an unusually long vehicle. Generally it is difficult, and often well-nigh impossible, to drive straight through the workshop from end to end in order to reach the spot at which the load is to be picked up.

It is more usual to be compelled to reverse into the shop. If it were only a matter of reversing in a straight line it would not be so difficult, but, as a rule, there are obstacles in the way, such as large machine tools or a part of the actual building. In consequence, the machinery carrier must be steered through various angles. Owing to the unusual wheelbase this is a very difficult matter, and, moreover, it is necessary, in certain instances, for the load carrier to be brought to rest within very fine limits of the desired position. Although the machine may be some 40 ft. long, an error of half an inch laterally is occasionally all that can be allowed.

With the trailer in question it is even possible to execute crabwise motion by the simple process of turning both bogies at right angles to the frame and applying the motive force to the trailer from one side or the other.

On the road also this system possesses many advantages, because it enables the trailer to be manceuvred far more rapidly around right-angle bends than would be the case if it steered only from its forward end. Cutting across corners, which is inevitable with only front-end steering, causes a great deal of the delay which is experienced in passing through areas with numerous buildings. The type of trailer in question should save much time and expense. Another advantage is that its improved mobility would cause less opposition to its passage on the part of local-government authorities.