THE NEW PALLADIUM CHASSIS.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

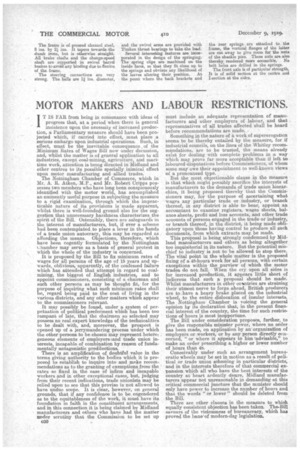

A Four-tormer Which Incorporates Many Detail Improvements.

THE new Palladium four-tonner is a very well-designed and stronglybuilt chassis suitable for all classes of work within its loading capacity: It is mainly built up of high-class components made by BORIC of the beat-known mariu7 facturers in America. The wheelbase is long, being 14 ft. 8 ins., and the long springs at the front bring the axle back to a certain extent, and give better distribution of the weight on the front and

• back axles.

A considerable number of improvements has been made on the new model. The wheels are of the east-steei. tu.bular spoked type, the chief novelty, in Which is that the wheels 8,PG cored from the bottom of the spokes so that no .grit drops from the rims into the hubs, as sometimes occurs with •wheels cored in the ordinary way. The Com holes are altareted _round the hub at the sides of the

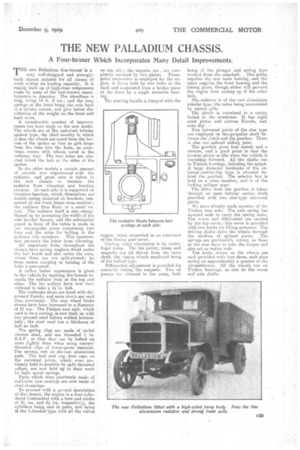

spokes. • In the older models a certain amount of trouble was experienced with the radiator, and great care is taken in

the new •ohassis insulate the radiator from vibration and bending stresses. At each side it is supported on trunnkn bearings, which, themselves, are double spring mounted on brackets supported by the front frame cress riseither ; the radiator thus floats to a small extent. The radiator itself is also strengthened up by increasing the width of the side bracket flanges, Fled the substantial guard in front of the tubas is made in ens rectangular piece comprising two bars and the sides for belting to the radiator side members. This conetractie]] prevents the latter from vibrating.

All important bolts throughout the chassis have spring wa4hers fitted under the bolt heads and also under the nuts, where theseare not split-pinned ; by, these means creeping or turning of the bolts is prevented.

A rather better appearance isgiven to the vehiele by tapering the bonnet towards the radiator both at the top and sides. The fan pulleys have now been widened to take a 11 in. belt.

The footbrake shoes are lined with diepressed Feeodo, and more rivets are used than previously. The rear wheel brake detuns have been increased to a'diameter of 21 in The Timken roar axle, which used to be a casting, is now built up with two pressed steel halves welded.horizontally ; the steel used has a thickness of half an inch.

The spring clips are made Of nickel chrome steel, and are threaded 1 in. B.S.F., so that they can be bolted up more tightly than when using coarser-threaded clips of lower-grade material. The springs rest on die-cast aluminium pads. The ball and cup,. dust caps on the universal joints, which were previously held in position, by split threaded collars, are now held up to their work by light spiral springs.

Parts which were previously made of malleable iron castings are now made of steel stampings.

To proceed with a ger.eral description of the chassis, the engine is a four-eylin&lied Continental with a bore and stroke

of 41 ins, and ins. respective:y, the cylindera beiaig east in pairs, and being of the leheaded type with all the valves on one side; the tappets, etc., are corti pletely enclosed by two plates. Threepoint suspension is entployed for the engine, it being held by two bolts at the back and suspended from a bridge piece at the front by a single trunnion bearing.

The starting handle is integral with the engine, being supported in an extension of the timing gear cover.

Geoltog water circulation is by centrifugal pump. The fan pulley, pump and magneto are all driven from the same shaft, the timing wheels employed being of the helical type.

Differeetial adjustment is provided for correctly timing the magneto. Two oil pumps are situated in the sunup, both being of this plunger and spring typo worked from the camshaft, One pump supplies the rear main bearing, and the other suppkes the front bearing and the timing gears, though either will prevent the engine from seizing up if the ether fails.

The radiator is of the cut aluminitun tubular type, the tubes being surrounded by square gills.

..The clutch is contained in a casing bolted to the crankcase. It has eightsteel plates and sixteen Ferodo, and runs dry.

Two universal joints of the star type are employed on the ipropeller shaft between the eluteh and the gearbox. There is also one plined sliding joint.

The gearbox gives four speeds and a

reverse, and goad point he that the reverse pinion is idle when the vehicle is t•ravelling forward. All the shafts run -in Timken bearings, including the spigot. A large diameter foetbrake of the external-contracting type is situated behind the gearbox. The selector box is held on a erross member, and is of the locking calliper type.

Thedrive from the gearbox is taken through an open tubular cardan shaft provided with two star-type universal joints.

We have. already made mention of the

• Timken rear axle. The axle casing has squared ends to carry, the spring seats. The worm and differential are carried by the top cover; this cover is provided with two hooks for lifting-purposes.' The driving shafts drive the wheels through the medium of splined plates. The springs are particularly strong, a-s those at the rear have to take the torque and also act as radius rods.

The brake drums on the wheels are each provided with four shoes, each shoe acting ou approximately a quarter of the circumference. All the wheels run on Timken -bearings, as also do the warm and axle shafts.

The frame is of pressed channel steel, 8 ins. by 21 ins. It tapers towards the dumb irons, but is otherwise straight. All brake shafts and the change-speed shaft are supported in swivel barrel bushes to-avoid any binding due to flexion of the frame.

The steering connections are very strong. The balls are l ins, diameter, and the swivel arms are provided with Timken thrust bearings to take the load.

Several interesting features are incorporated in the design of the springing. The spring clips are machined on the inside faces, so that they fit close up to the springs and obviate any likelihood of the leaves altering their position. At the point where the back brackets and the rear springs are attached to the frame, the vertical flanges of the latter are cut away to give room for the nuts of the shackle pins. These nuts are also thereby rendered more accessible. No bolt holes are drilled in the springs.

The front axle is of particular strength. It is of solid section at the centre and I-section at the sides.