ELECTROMOBILE ELECTRICS.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

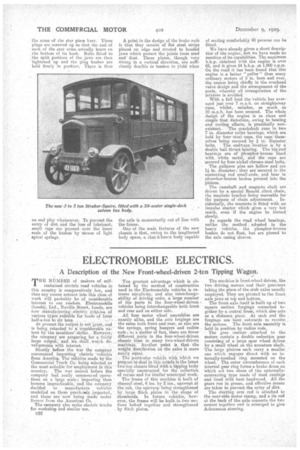

A Description of the New Front-wheel-driven 2-ton Tipping Wagon.

MILE NUAIBER of makers of self. contained electric road vehicles in this country is comparatively few, and

thus any recent entrant into this class of work will probably be of considerable interest to our readers. Electromobile (Leeds), Ltd., Neville Street, Leeds, are

now manufacturing -electric *ehiciee, of various types suitable for loads a from

half-a-ton to six tons:

At„present the.outPut is not great, and ' is being retarded to-,a;.COnsiderable tent by the moulders ,strike. However, the company .are preparing-for a fairly large output,' and ...we shall watch de, velopments with interest. Shortly, before the war 'the company . commenced importing -electric 'vehicles from Anieriea. The vehiO!es made by the Commercial Truck Co. being selected as the racist suitable-for amplOymeht in this country,. The war ensued before the -company had really commenced operations on a large scale ; importing then ' became impracticable,' and the company decided to 'manufacture vehicles modelled on those previnaery .imported, and these are . now being made under

licence from the American Co. The company also make electric trucks for workshop and similar am. • C22

The greatest advantage which is obtained by the method of construction used in the Eleetromobile vehicles is extreme simplicity, and also interchangeability of driving units, a large number of the parts in the four-wheel-driven vehicles being.interchangeablo both front and rear and on either side.

All four motor wheel 'assemblies are exactly alike, and the axle forgings are the same both front and. rear, as also are the springs, spring hangers and radius rods; a.6 a /natter of fact, there are fewer -different parts in the four-wheel-driven chassis than in Many two-wheel-driven machineS:..„ Another point is that the weight distribution on the axles is more

nearly equal. . •

The particular vehicle with which we propose to deal in this atrtiolo is the latest two-ton chassis fitted:With a tipping body specially • constructed for the collection of refuse and for 'similar municipal work. The.fraine of this machine is built of channel 'steel, 4 ins. by 2 ins., upswept at the cab, the up:sWeep being strengthened IV large flitch .plates in the shape of rhomboids. In future vehicles-, however, the frame will be built in two sections bolted together and strengthened by. flitch plates.

The machine is front-wheel driven, the two driving motors and their gearcases taking the place of the stub axles usually employed. They are pivoted to the front axle jaws at top and bottom. The front axle itself is built up of two square section forgings connecteci together by a central truss, which also acts as a...distanee piece. At each end the forgings are bent outwards to receive, the motors. The front axle assembly is held in position by radius rods. The gear. casings attached to the

motors contain a double reduction gear consisting of a large spur wheel driven by a small wheel on the armature shaft. The large pinions each carry a smaller one which engages direct with an internally-toothed ring mounted on the wheel. The onter circumference of each internal gear ring farms a brake drum on which act two shoes of the externallycontracting type made of steel castings and lined with bent hardwood. All the gears run in grease, and effective means are taken to prevent the entry of dirt. The steering arm red is attached to the near-side motor casing, and a tie rod at the back of the axle connects the two motori together and is arranged to give Ackermann steering.

The footbrake acts on large diameter drums bolted to the rear wheels the shoes in this case also being of the externally-contracting type.

The back axle is a solid rectangular steel forging and is quite straight.

The steel tipping body hinges at the extreme end of the frame and, owing to the final drive being at the front, this tody can be kept so low that it is quite easy for is man to tip refuse from his shoulder into it.

The batteries are situated .under the driver's seat and -under the whole of the Lab. Behind the seat and over the batteries is positioned a winch, driven by a small electric motor throagh the Medium of a double-reduction gear consisting of a worm and. wheel and two spur wheels ; wire rope from the win-I passes over a pulley at the top of and at the back of the cab, and thence round a floating pulley which is attached by means Of two short lengths off chain to extension brackets at the front of the body. The' rope is then carried back and it is fastened close to the pulley on the cab ; the latter, in order to take the strain, is considerably strengthened. by a. framework built of angle iron and fitted with tie rods. The tipping gear is operated by a senarate switch and resistance at the offside of the driver's seat.

The controller, which is situated at the pat OM 411 the steering column, is operated by a hand wheel placed below the steering wheel. The Control is 'arranged so that at half speed the motors are in series. whilst at fall speed they are in paralfei_ This enables the driver to run his machine at low speeds for considerable periods without Wasting energy in resistances. The whole control is exceptionally siniple, and the only inetruments to be seen on the das.libtlarcl aro an amv±.re meter and a fuse box.

The driver is well protected by the cab, and a windscreen which covers the ,Ivhole width protects the front of the tab. This windscreen is made in two

• sectione, divided vertically, and half of the screen in front of the driver -pivots tsp.

The motors are each 80 volts, 22 amps., rind ran be overloaded up to 300 per cent-. Creat care has been taken in the design to render all the important parts accessible. This particularly applies to the motors, in each of which the 'front part of the casing swings open in order to give access to the brushes for examinelion and adjustment. The armatures run in ball bearings, whilst the intermediate gearshafts run in long roller bearings. The wheels are of the wood artillery type and run on Timken roller bearings. The standard batteries fitted are Ironelad-Exide, but Edison can be fitted if required.

The maximum height from the ground to the top of the body is 4 ft. 9 ins., and, if particularly requitied, this distance tan be reduced to 4 ft. 6 ins.

As regards the other vehicles which al'a manufactured by the company, the heavier types are fitted with four driving motors, all four wheels being driven. The same motor-driving units are employed'on these vehicles as are employed • on the front-wheel driven chassis, except that different gear ratios are, oil course, used. I-Talf-ton, one-ton, and two-ton rear-wheel-driven chassis are also built. Itt these machines concentric gearing is employed. The pinion on the armature of each motor engages with three Spur gears which are carried by studs mounted integral with the driving shafts. Each of these pinions carries a smaller pinion engaging with an internally toothed ring which pressed into the gearcase and keyed. In the ease of the rear-wheel-driven machines, the two motors are held in position by two channel-steel axle members which are bolted to the gear casings. The rear springs are mounted on the tops of these casings, and extensions of the casings form the axle spindles. These extensions are made of die-forged, heattreated alloy steel. The motors are bolted to the inner ' sides of the casings in line with the whale axle. ; This construction gives a very strong but light axle, -so that the unsprung weight is reduced to the minunum.

The ease with which these vehicles can be controlled, even by semi-skilled drivers, .and the speed with which they can • be I .stopped andstarted, render them' particularly Suitable for municipal work, Suck ai duetCollection, where frequent step a-re necessary.