USG conversion battles through

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

BEDFORD developed the 4x4 M-type primarily to meet a mili tary requirement. While a civilian version is available, it reflects its origins in weight and size proving to be of a heavier weight class than many operators would wish for. A gvw of 11 tons restricts on-road operation to drivers who have at least an HGV Class ill licence.

In order to satisfy a wider civilian market United Service Garage (Portsmouth) Ltd, part of the Wincanton Group, converts Bedford chassis, for use by nonhgv drivers, to four-wheel drive. The company uses,for the most part, components having recognised Bedford part numbers.

obvious advantages are gained when vehicles are maintained and operated in remote areas. Only the drive housing and front-axle driveioint assemblies are not standard Bedford parts.

The complete UK range extends from 5.6 to 12.35 tons gvw.

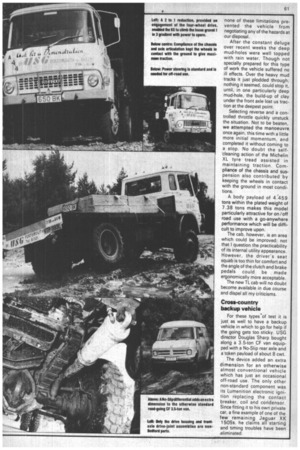

Across the front of USG's KE 4x4 demonstrator, plated at 7.38 tons gvw, it says -Ask for a demonstration.I did, but I chose the time and place. We took it to an army test ground in the South of England.

I drove it over a course which we normally reserve for heavyweight 6x4 and 8x4 tippers to assess rough road performance.

Owing to the much shorter wheelbase and light gvw, the general quality of the ride bore no comparison to the heavier class of vehicle and the rate of progress was necessarily slower by as much as one third as a result.

At this stage the vehicle remained in two-wheel drive aided only by the No-Slip automatic mechanical difflock.

Only later, over a much steeper loose gravel section with ascending gradients of 1 in 3 and descending gradients even steeper, did it become necessary, through a lack of power, to engage four-wheel drive — an operation which is executed from within the cab but which requires the vehicle to be stationary Engagement of the fourwheel drive effects a 2 to 1 gear reduction and was all that was needed to continue with the laden vehicle. As with the military M-type, the KE 4x4 has a claimed gradeability of almost 1 in 2. Downhill running was just as impressive. From moving slowly away at the top of the gradient engine braking was sufficient to contain the vehic le's speed at a very low rate without any assistance from the service brakes.

Steering of the test vehicle was assisted by an Airomatic ram. The difference in feel between twoand four-wheel drive was hardly perceptible. However, Douglas Sharp, managing director of USG, told me that a hydraulic system, powered by an engine driven pump, is to be fitted to future models.

The existing system is linked into the air side of the braking system and tends to reduce the pressure available to the servo, but on the test vehicle neither the brakes nor the steering became heavy at any time.

Fitted here with a J-type front axle the civilian conversion, at a cost of about E4000 on top of the basic model, shows an area of advantage over its military counterpart. A steering angle of 32 gives the long wheelbase 3.65m (151 in) KE chassis a wall to wall turning measurement of approximately 16m (52 5ft), which is about equivalent to the kerb to kerb dimension given for the short wheelbase 3.5m 138in) M-type having steering angle of only 27' Manoeuvrability is a positive asset in negotiating narrow gateways from singletrack lanes and in other confined areas. In maintaining a more acceptable load height for civilian use the KE sacrifices something in approach and departure angles as well as belly clearance. In practice, however, a none of these limitations prevented the vehicle from negotiating any of the hazards at our disposal.

After the constant deluge over recent weeks the deep mud-holes were well topped with rain water. Though not specially prepared for this type of work the vehicle suffered no ill effects. Over the heavy mud tracks it just plodded through; nothing it seemed, could stop it, until, in one particularly deep mud-hole, the build-up of clay under the front axle lost us traction at the deepest point.

Selecting reverse and a controlled throttle quickly unstuck the situation. Not to be beaten, we attempted the manoeuvre once again, this time with a little more initial momentum, and completed it without coming to a stop. No doubt the selfcleaning action of the Michelin XL tyre tread assisted in maintaining traction. Compliance of the chassis and suspension also contributed by keeping the wheels in contact with the ground in most conditions.

A body payload of 4.459 tons within the plated weight of 7.38 tons makes this model particularly attractive for on /off road use with a go-anywhere performance which will be difficult to improve upon.

The cab, however, is an area which could be improved; not that I question the practicability of its internal utility appearance. However, the driver's seat squab is too thin for comfort and the angle of the clutch and brake pedals could be made ergonomically more acceptable.

The new TL cab will no doubt become available in due course and dispel all my criticisms.

Cross-country backup vehicle For these types-of test it is just as well to have a backup

vehicle in which to go for help if the going gets too sticky. USG director Douglas Sharp bought along a 3.5-ton CF van equipped with a No-Slip rear axle and a token payload of about 8 cwt.

The device added an extra dimension for an otherwise almost conventional vehicle which has just an occasional off-road use. The only other non-standard component was its Lumenition electronic ignition replacing the contact breaker, coil and coridensor. Since fitting it to his own private car, a fine example of one of the few remaining Jaguar XK 1 5OSs, he claims all starting and timing troubles have been .eliminated.