Lower unladen weight saves money on pints

Page 59

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

WHEN the first models in the TM range were introduced at the 1974 Commercial Motor Show, Bedford had every reason to be optimistic about their future.

The CF van was selling strongly and the TK range, first introduced in 1960, was on the way to breaking all sales records for a British lorry. So with such ;trong representation in the van and light / mid-weight sectors why shouldn't a heavyweight :ontender do well?

But sadly, even Bedford itself -nust feel that sales of the TM .ange have not lived up to ex

)ectations. Total sales of the 3omplete range to date are just wer 7500, with the 16-ton wo-axle rigid being the most )opular model in a range that )oes right up to 42 tonnes )ross. This model has the Bedord 500 engine, while options )n the larger models are the ;ix-cylinder Detroit Diesel, the tight-cylinder Detroit and the 1:ummins NTE 290.

Main attractions of the TM vhen it was launched were that t was British and that it had a elatively low unladen weight. )n this first point, many large Terators, particularly in the )wn-account sector, like to be ,een to buy British and so were nterested in the TM, bearing in nind the success of the TK.

But more important to many iperators was the low kerb veight of the TM. The twotroke, six-cylinder Detroit. )iesel 6V-71 engine was the ,nly engine option initially vailable and is a light power init considering its output. The est of the tractive unit is also far rom heavy, with, for instance, he use of tapering leaf springs eeping the weight down. The ?suit is an all-round light unit nd the TM 3250 with the sixylinder Detroit engine was, and till is, one of the lightest 32)nners around.

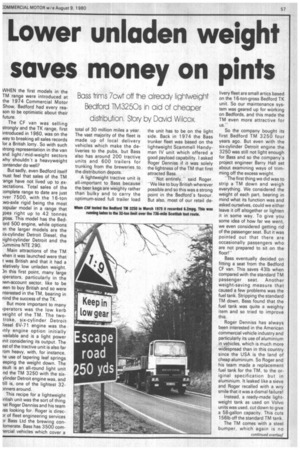

This recipe for a lightweight ritish unit was the sort of thing at Roger Denniss and his team /as looking for. Roger is direc x of fleet engineering services x Bass Ltd the brewing conlomerate. Bass has 3500 comlercial vehicles which cover a total of 30 million miles a year. The vast majority of the fleet is made up of local delivery vehicles which make the deliveries to the pubs, but Bass also has around 200 tractive units and 600 trailers for trunking from the breweries to the distribution depots.

A lightweight tractive unit is all-important to Bass because the beer kegs are weighty rather than bulky and to carry the optimum-sized full trailer load the unit has to be on the light side. Back in 1974 the Bass trunker fleet was based on the lightweight Scammell Handyman IV unit which offered a good payload capability. I asked Roger Denniss if it was solely the lightness of the TM that first attracted Bass.

"Not entirely,'" said Roger. "We like to buy British wherever possible and so this was a strong point in the Bedford's favour. But also, most of our retail de

livery fleet are small artics based on the 16-ton-gross Bedford TK unit. So our maintenance system was geared up for working on Bedfords, and this made the TM even more attractive for us."

So the company bought its first Bedford TM 3250 four years ago. But even with the six-cylinder Detroit engine the 3250 was still not light enough for Bass and so the company's project engineer Barry Hall set about examining ways of trimming off the excess weight.

"The first thing we did was to strip a TM down and weigh everything. We considered the weight of each part, bearing in mind what its function was and asked ourselves, could we either leave it off altogether or lighten it in some way. To give you some idea of how far we went, we even considered getting rid of the passenger seat. But it was pointed out that there are occasionally passengers who are not prepared to sit on the floor!"

Bass eventually decided on fitting a seat from the Bedford CF van. This saves 43Ib when compared with the standard TM passenger seat. Another weight-saving measure that caused a few problems was the fuel tank. Stripping the standard TM down, Bass found that the fuel tank was quite a weighty item and so tried to improve this.

Roger Denniss has always been interested in the American commercial vehicle industry and particularly its use of aluminium in vehicles, which is much more widespread than in this country since the USA is the land of cheap aluminium. So Roger and his team made a replacement fuel tank for the TM, to the original specification but in aluminium. It leaked like a sieve and Roger recalled with a wry smile that it was a dismal failure! Instead, a ready-made lightweight tank as used on Volvo units was used, cut down to give

a 58-gallon capacity. This cuts 156Ib off the standard TM tank. The TM comes with a steel bumper, which again is no continued overleaf

lightweight and so Bass replaced this with an aluminium version. This is the most expensive modification but it does save another 60 lb. Similarly, the cab steps were removed and aluminium ones substituted weighing 21 lb less.

Another item that was reworked in aluminium is the battery box. AC Delco Freedom batteries were used in place of the conventional ones and together with their lightweight carrier save 35 lb. The air intake at the back of the cab has been shortened and generally modified enab enabling a further 50 lb to be lost. Another 10 lb was saved by the use of a special type of plastic in the cab back windows in place of glass.

The front panel on the cab was replaced by an aluminium version as were the front mudguard/wing fitments. In addition to all these modifications there are a whole range of smaller detail changes which all contribute towards weight saving. For example, the engine lift hook is left off, saving seven pounds. Although this seems relatively minor it does help, and, as Roger Denniss commented: -Why carry an engine lift hook around with you? It serves no purpose on the road."

In all, Bass has trimmed about seven hundredweight off the standard TM 3250. Said Roger: "We had to get down to a kerb weight of 5 tons 8cwt including a full tank of diesel. This means that when it's pulling one of our 40ft flat bed trailers it gives us a 21.65-ton payload capacity.

Is all this work really worth it? Roger pointed out that much of the weight saving is achieved by leaving things off rather than adding new parts, and so this should cost very little. The original conversion work on the first units was carried out by Bedford distributor USG of Portsmouth, but on the later batch much of the modification was done at the Bedford factory under special vehicle orders.

Roger considers all that is done is cost effective, adding that there are other ways of saving even more weight but that these may not be. "For instance we could have saved another 300lb or so by specifying alloy wheels, but these would have cost too much to make them worth while."

Getting away from the lightening exercise, how have the TMs performed for Bass? The bulk of the company's trunking units are in fact Volvo F7s (an even lighter unit) so Bass has the opportunity to make a side-byside comparison. Predictably, it is the Bedford's fuel consumption that counts against it. The Detroit Diesel 6V-71 two-stroke engine offers a good power out put for its cubic capacity (222bhp from 6.9 litres) and is largely responsible for the TM's low kerb weight. But this is also achieved somewhat at the expense of fuel consumption.

When CM tested the sixcylinder Detroit engined TM

3250 in March 1975 we

recorded an overall consumption of 6.2mpg over the Scottish

test route, a figure we called "slightly disappointing". Bass finds that its TMs are achieving

about 7mpg. Since its trunkers are worked quite intensively and average 80,000-100,000 miles each year, a small deficit in fuel consumption makes itself felt. Bass really has gone into fine detail when it comes to component reliability, using Institute of Road Transport Engineers vehicle maintenance recording standards and Vauxhall Motors have been enthusiastic in following this up.

As a result, Bass has restricted its TM fleet to ten, all of which are based at one depot in the Midlands.

Bearing in mind Bass' goahead attitude and willingness to try to improve the basic model to suit the company's needs, it is not surprising to learn that it has investigated fuel saving techni ques. These could possibly improve the Bedford's standing, I suggested.

"In theory, yes," said Roger. "But it hasn't worked out like that in practice. We have conducted a whole range of tests at MIRA with all sorts of fuel saving devices. Temperature controlled engine fans, automatic radiator blinds, aerofoils, synthetic oil — we've tried the lot. They all gave some improvement in consumption under the controlled conditions at MIRA, but in real operating conditions any improvement tends to get swallowed up."

Roger Denniss said that he has found that even the cabmounted aerofoils which are finding favour with other large own-account operators have not saved fuel. If they do give any benefit Roger believes it is in performance and as a result the units are going faster and using more fuel. The only economy measure that he has found effective is to drive more slowly!

With reference to any reliability difficulties, at least accessibility on the TM is good with a hinged front panel for checking the radiator and oil levels and a 60 degree tilt cab for more major work.

Bass has been able to work out exactly how much it costs to maintain each vehicle and this helped to assess the relative costs of each type. Roger Dennis told me that vehicle maintenance cost Bass a total of about £4 million last year (that includes original equipment tyres). The system used is unusual and warrants a description.

It is another example of Roger's interest in the American way of doing things and the Bass system has its origin in the States. There are a minimum number of service schedules for the Bass vehicles. Instead, all of them are inspected at regular intervals. For each make and model there is a set of acceptable tolerances which measure the amount of wear or use for all the components normally covered in conventional maintenance. If any particular item or component doesn't meet these tolerances then it's replaced. But if there is a satisfactory amount of use or life left then it is left alone, irrespective of its previous life.

This may sound quite obvious, but as Roger Denniss explained the conventional regular maintenance interval system will sometimes lead to items being replaced before their working life is expired. For instance, brake components are often changed at set mileage intervals, whereas their life will depend greatly on the individual vehicle and type of operation.

Even the engine oil in the Bass vehicles isn't changed at predetermined intervals. Samples are taken from each vehicle and analysed in small portable analysers, and this will decide if the oil needs changing.

Said Roger Denniss: -We try to find the optimum maintenance level where we give the best maintenance bin at the lowest cost. Our system means that everything is inspected frequently but every item is used to its full before we throw it away."

To further simplify maintenance, Bass has developed a number of little ruses to make routine work as little and as easy as possible. For instance, the planking for the retail fleet trailers takes quite a battering from the kegs and so the company has designed a system which means the individual planks are easier to remove and replace. Similarly, the side raves on the trailers are bare aluminium so that they don't need frequent painting to keep them smart. Minimum maintenance AC-Delco Freedom batteries are also used. This sort of thing gives worthwhile savings when applied to 3500 vehicles.

Bass has also carried out a project to design a 16-ton flat rigid specifically for retail deliveries. It is based on the Bedford TK four-wheel rigid which has been lightened in a similar way to the TM units. But more importantly, its platform heighi — which should be as low as possible to minimise unloading effort — has been substantially reduced. The suspension and rear axle assembly has been extensively modified to achieve this and the platform decking has also been cleverly arranged to keep the overall height down to an absolute minimum.

With Bass being so weightconscious how does the company feel about the likely future rise in maximum gross weights? Any increase in gross vehicle weight would be seen as an opportunity to increase overall productivity and efficiency. Bass points out that current theoretical calculations show that 36 tonnes would be the most efficient, assuming that the total length limit stays at 15 metres.

No matter what happens to maximum weights in the com ing months as a result of the Armitage Inquiry into the mat ter, Bass would always be in favour of cost-effective weight reduction.

Higher weights would also mean that any move towards curtainsiders could be easier since their slight weight penalty over a flat trailer would not be so critical. Like many other companies (especially the brewers) Bass has been evaluating curtainsiders because of the better load retention and protection they offer.

If the weights do go up I got the impression that Roger Denniss and Bass wouldn't stops worrying about unladen weight altogether. He is obviously concerned about overall transport efficiency and a heavy unit isn't an efficient one in his eyes, even if it is legal. For this reason he would still like manufacturers to work at producing lighter vehicles and hopes that the end of the constraint of 32-ton operations doesn't lead to manufacturers giving less thought to unladen weights_