3. Container transfer systems

Page 83

Page 84

Page 85

Page 86

If you've noticed an error in this article please click here to report it so we can fix it.

WHEN the container revolution eventually swings into top gear all sizable general haulage contractors with no equipment for handling containers at depots will be at a competitive disadvantage.

The fortunate minority of hauliers may be able to offer specialized vehicles—skeletal trailers for example—and undertake regular shuttle services from customers' premises to docks or inland container terminals. But most operators are likely to be involved in complex container movements of full and empty containers and the possession of container-handling equipment will give the necessary flexibility for profitable work.

The range of available equipment is extraordinarily wide and the choice of equipment must be governed by the degree of use anticipated.

Gantries have a long history in transport and their use in Freightliner terminals and ports is well known. The makers of the large gantry cranes claim that handling a container is faster than by any alternative equipment. The ability of the crane operator to track crab-wise across several rows of containers or vehicles and to position precisely with a gun-sight, is certainly valuable. Another advantage claimed with the use of heavier rail-mounted gantries is that ground consolidation costs are minimized.

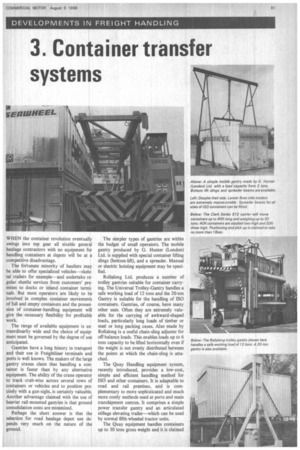

Perhaps the short answer is that the selection for road haulage depot use depends very much on the nature of the ground. The simpler types of gantries are within the budget of small operators. The mobile gantry produced by G. Hunter (London) Ltd. is supplied with special container lifting slings (bottom-lift), and a spreader. Manual or electric hoisting equipment may be specified.

Rollalong Ltd. produces a number of trolley gantries suitable for container carrying. The Universal Trolley-Gantry handles a safe working load of 12 tons and the 20-ton Gantry is suitable for the handling of ISO containers. Gantries, of course, have many other uses. Often they are extremely valuable for the carrying of awkward-shaped loads, particularly long loads of timber or steel or long packing cases. Also made by Rollalong is a useful chain-sling adjuster for off-balance loads. This enables loads up to 6 tons capacity to be lifted horizontally even if the weight is not evenly distributed between the points at which the chain-sling is attached.

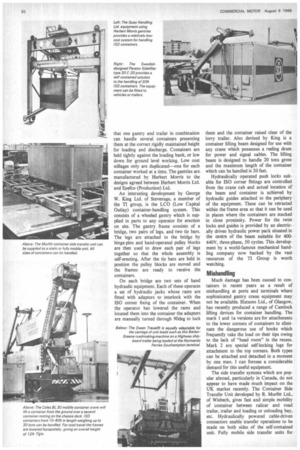

The Quay Handling equipment system, recently introduced, provides a low-cost, simple and efficient handling method for ISO and other containers. It is adaptable to road and rail premises, and is complementary to more sophisticated and much more costly methods used at ports and main transhipment centres. It comprises a simple power transfer gantry and an articulated stillage elevating trailer—which can be used by normal fifth-wheeled tractor units.

The Quay equipment handles containers up to 30 tons gross weight and it is claimed that one gantry and trailer in combination can handle several containers presenting them at the correct rigidly maintained height for loading and discharge. Containers are held tightly against the loading bank, or low down for ground level working. Low cost stillages only are duplicated—one for each container worked at a time. The gantries are. manufactured by Herbert Morris to the designs agreed between Herbert Morris Ltd. ' and Enefco (Production) Ltd.

An interesting development by George W. King Ltd. of Stevenage, a member of the TI group, is the LCO (Low Capital Outlay) container-handling system. This consists of a wheeled gantry which is supplied in parts to any operator for erection on site. The gantry frame consists of a bridge, two pairs of legs, and two tie bars. The legs are attached to the bridge by hinge-pins and hand-operated pulley blocks are then used to draw each pair of legs together so that the whole assembly is self-erecting. After the tie bars are held in position the pulley blocks are moved and the frames are ready to receive the containers.

On each bridge are twO sets of hand hydraulic equipment. Each of these operates a set of hydraulic jacks whose rams are fitted with adapters to interlock with the ISO corner fixing of the container. When the operator has lowered the rams and located them into the container the adapters are manually turned through 90deg to lock them and the container raised clear of the lorry trailer. Also devised by King is a container lifting beam designed for use with any crane which possesses a reeling drum for power and signal cables. The lifting beam is designed to handle 20 tons gross and the maximum length of the container which can be handled is 20 feet.

Hydraulically operated push locks suitable for ISO corner fittings are controlled from the crane cab and actual location of the beam and container is achieved by hydraulic guides attached to the periphery of the equipment. These can be retracted within the frame area so that it can be used in places where the containers are stacked in close proximity. Power for the twist locks and guides is provided by an electrically driven hydraulic power pack situated in the centre of the beam suitable for 400440V, three-phase, 50 cycles. This development by a world-famous mechanical handling company now backed by the vast resources of the TI Group is worth watching.

Mishandling

Much damage has been caused to containers in recent years as a result of mishandling at ports and terminals where sophisticated gantry crane equipment may not be available. Hutsons Ltd., of Glasgow, has recently produced a range of Camlock lifting devices for container handling. The mark I and la versions are for attachments to the lower corners of containers to eliminate the dangerous use of hooks which frequently take the load on their tips owing to the lack of "head room" in the recess. Mark 2 are special self-locking lugs for attachment to the top corners. Both types can be attached and detached in a moment by one man. I can foresee a considerable demand for this useful equipment.

The side transfer systems which are popWar abroad, particularly in Canada, do not appear to have made much impact on the UK market recently. The Container Side Transfer Unit developed by R. Murfitt Ltd., of Wisbech, gives fast and simple mobility of container between railcar and road trailer, trailer and loading or unloading bay. etc. Hydraulically powered cable-driven connectors enable transfer operations to be made on both sides of the self-contained unit. Fully mobile side transfer units for road operations are also available.

Another side transfer system, that of Solar-Steadman Containers Ltd., of Burscough, Lancs, seems to offer many cost advantages but its widespread application in the UK may have been slowed down because minor modifications to the under-side of containers used with the system are necessary. An adapter is supplied to convert any container to the system requirements. The Steadman changeover operation is claimed to take no more than two minutes. Retractable or movable legs allow the container to be parked anywhere.

The Multi-Lift system made by MuItilift Ltd., of Broughton, near Shrewsbury, enables vehicles to carry ISO Containers which can be loaded and unloaded anywhere without any assistance or other equipment being required. This facility in itself is likely to be highly valued by road hauliers. The system, designed in Finland is said to be well: proved and in use in many countries under extreme climatic conditions. Despite the 15deg tipping angle it is claimed that no displacement of cargo occurs when the containers are lowered down the ramp to the ground. Exchangeable bodies for all types of standard commercial vehicles chassis are available to handle 8-, 12-, and 16-ton loads.

I understand that heavier versions suitable for handling 20ft ISO containers, which may carry loads of 18 tons or so, are likely to be available soon. Of course, in practice, by no means all 20ft containers will be loaded to capacity and any container user who will not require to load more than 16 tons may be interested in this system.

The Multilift KX loader handles containers free-standing on legs but when carrying a container from ground level it is necessary for the container to be raised a few inches from the ground on blocks. This permits the mechanism to connect with serrated rollers which are driven by an 8-ton capacity hydraulic motor, and the body moves slowly forward on to the vehicle, while the latter is reversing, the four legs then being lifted from the ground, and folded alongside the frame of the body. I understand that this system is particularly in use for liquid gas bottles which, for safety reasons, must not be tipped.

No review of container handling methods would be complete without reference to mobile cranes. At Felixstowe, where two large Vickers Paceco transporter cranes have been installed, supplementary container movements around the dock side area are by a Jones 15-30 mobile crane which can move the containers rapidly about the container park and stack them three high where required.

The Jones 15-30 will comfortably lift 20 tons at 1511 radius to a height of 2511. Cranes of this type are becoming increasingly popular at small ports where they are used to off-load small coastal vessels —some of which may carry containers as part of the general cargo—or they can be called upon to help with normal dockside lifting work. At Portsmouth, Jersey potatoes pre-stacked on unitized pallets, weighing some 10 tons, are off-loaded by Jones 15-30 mobile cranes. The equipment is said to be capable of off-loading 80 tons in under 30min, so that most ships can be turned round on a single tide. The British Crane and Excavator Corporation Ltd., maker of Coles cranes, has developed the interesting BL 30 container mobile crane for use in container parks. Equipment of this complexity will obviously require highly skilled operators and, one feels, maintenance personnel. More conventional mobile equipment by Coles is the Ranger fully mobile container crane. The manufacturer of the Parator sidelifter was inspired to develop its equipment by the realization that door-to-door transportation is often limited, because the smaller terminals and many traders have had no suitable off-loading equipment. The turnover has often been too small to justify investment in fixed equipment. The sidelifter can be mounted on self-driven vehicles and trailers and it is thought will he popular for intensive local delivery work. The agents for this country are Ailsa Trucks (Northern) Ltd. of Barrhead, Glasgow.

The Shaw Sideloader handled by Barlow Myers Ltd., of Windsor, Berkshire, is designed to handle 20-ton containers of 20 and 30ft lengths. It stacks containers three high when fitted with a 26ft mast and makes excellent use of storage space in terminals. The Shaw loader 560 C is equipped with a top-lift attachment having a standard spread of 20ft. Alternative attachments are available, one with 30ft spread and one with adjustable 20-30ft spread. All locking, positioning and handling movements are hydraulically operated, controlled by the driver from his cab.

The ingenuity of fork-lift truck manufacturers in adapting their standard products for container handling operations is remarkable. The Towmotor organization, a subsidiary of Caterpillar Tractor Company, has recently introduced a top-handling container-lifting device which locks into ISO corner fittings. The truck-mounted control panel signals locking-pin insertion and locking completion. Movable arms and frame adjust for uneven container position.

The Towmotor container system has low initial equipment cost (up to 50 per cent less than carriers and cranes). Equipment maintenance and driver training expenses are also minimized. It is convenient, for users of the Towmotor fork-lift truck for conventional load carrying, to be able to convert it to container handling in less than 10 minutes, without the use of' special tools. (A special stand is used for the attachments and forks.) The Owen Travelift self-propelled straddle-lift transporter cranes for cargo and industrial handling are well known, particularly in the larger terminals. The Travelift is a rubber-tyred, highly manoeuvrable type of lifting system designed to handle loads of 25,000 to 100,000lb. All operations are remotely controlled by the operator who is afforded a clear view of load handling. Most loads can he handled by traversing trolley or fixed lifting points for slings at each corner. The Travelift is also adaptable to clamps, magnets, vacuum lifts, slings, grapples and other appliances.