1. Self-contained demountable bulk-container systems

Page 74

Page 77

If you've noticed an error in this article please click here to report it so we can fix it.

THE extraordinary growth in the number of users of demountable bulk container systems is clear evidence of the economic advantages Of the principle in the right application. Particularly for short-distance shuttle operations the use of this type of equipment offers unrivalled opportunities for the intensive use of the prime mover. The capital costs of the skips must, of course, be recovered from users but labour productivity is usually so high that this presents no difficulty.

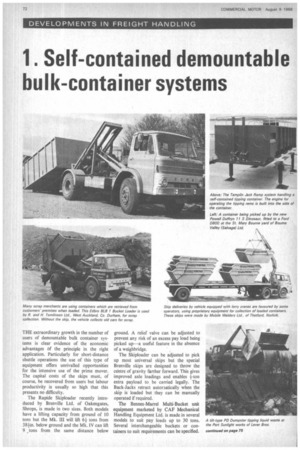

The Rapide Skiploader recently introduced by Brenville Ltd. of Oakengates. Shrops, is made in two sizes. Both models have a lifting capacity from ground of 10 tons but the Mk. HI will lift 6+ tons from 38i-in. below ground and the Mk. IV can lift 9 ,tons from the same distance below ground. A relief valve can be adjusted to prevent any risk of an excess pay load being picked up—a useful feature in the absence of a weighbridge.

The Skiploader can be adjusted to pick up most universal skips but the special Brenville skips are designed to throw the centre of gravity farther forward. This gives improved axle loadings and enables +-ton extra payload to. be carried legally. The Back-Jacks retract automatically when the skip is loaded but they can be manually operated if required.

The Bennes-Marrel Multi-Bucket unit equipment marketed by CAF Mechanical Handling Equipment Ltd. is made in several models to suit pay loads up to 30 tons. Several interchangeable buckets or containers to suit requirements can be specified. The hydraulic oil tank and control valves are mounted in one assembly behind the vehicle cab—a feature that is helpful when major overhauls are required. Cab controls can be duplicated externally, if necessary.

The equipment incorporates patented rear roller jacks, enabling the driver to move a loaded bucket from a confined space without first hoisting on the vehicle deck. When the vehicle has moved to a clear space the final hoisting of the bucket takes place.

The Marrel Roll-On equipment enables the handling of containers or detachable bodies built to maximum legal width to suit all four-, sixand eight-wheeled chassis. The Roll-On can also be supplied for operation to the maximum gross weight, if required, of 32 tons. Anchotpac compaction equipment can be operated in conjunction with the Multi-Bucket and Roll-On systems.

The Dempster systems The Dempster systems—Dumpster, Dumpmaster, Dinosaur, and Sideloaderproduced by the Powell Duffryn Group under licence from the American patentees—are designed for mounting on standard chassis. Only one man, the driver of the Dempster-equipped vehicle, controls the picking up, transporting and unloading cycle.

Three basic Dumpster models are available with load capacities ranging up to 10 tons, using containers with capacities from 3 to 15 cu.yd. High dump versions of the three basic models are available for use when obstacles have to be negotiated, and containers specially suited to the handling of liquids and sludges can be supplied.

Dumpmaster bulk compaction units, in five basic models, are produced either with or without self-loading arms for lifting containers of up to 6 cu.yd. capacity and tipping contents into the vehicle's body. All models have full cross-section ram plates which can reduce load volumes by as much as two-thirds. The 52 cu.yd. model 52DB, for trailer mounting with any standard fifthwheel tractor, is not fitted with loading arms. Its compaction ram is powered by the engine of the tractor or by trailer-mounted diesel unit. Two models of the Dempster Dinosaur are available with load capacities of 10+ and 13 tons. The Dinosaur system consists of chassis-mounted hydraulic handling equipment and large demountable bodies. Preloaded bodies are picked up, set on the chassis, and either set down or tipped at the end of the journey.

The Freight Loader handling system introduced by She!yoke and Drewry Ltd., of Letchworth, Herts, utilizes skips, box containers, tank containers with capacities up to 800gal, and fiat pallets fitted with side rails. The transporter is a self-contained unit which can be mounted on a selection of proprietary chissis, suitably adapted. It comprises a rigid main frame with hydraulically operated arms to raise and lower the containers. Hydraulically operated stabilizer legs are self-levelling to compensate for uneven ground and may be individually adjusted to allow for operation of the unit on sloping ground.

N. Tamplin and Co. Ltd., of Birdham, Chichester, has long experience in the manufacture of demountable bodies. In the tipping range they are available from 8-18 tons capacity and from 15-25ft long. Auger models can be supplied to almost any length requirement and can be made to fit the largest trailers now being manufactured.

Three types of pneumatic discharge system are available for mounting on bulk tippers, standard flatbed vehicles and a third system, a self-powered combined blowercontainer employing a Volkswagen industrial petrol engine mounted in a sub-frame of a standard Tamplin container.

Tamplin also produces a jack-ramp system designed for removing fully loaded containers, enabling shuttle services to be operated; and gantries, of 2 or 3 ton capacity, for removing empty containers or cattle boxes from vehicles.