AcceleratiN )elivery by

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

LAUNDRY VANS

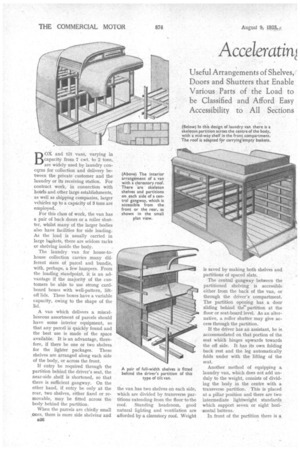

Useful Arrangements of Shelves, Doors and Shutters that Enable Various Parts of the Load to be Classified and Afford Easy Accessibility to All Sections

BOx and tilt vans, varying in capacity from 7 cwt. to 2 tons, are widely used by laundry concgrns for collection and delivery between the private customer and the laundry or its receiving station. For contract work, in connection with hotels and other large establishments, as well as shipping companies, larger vehicles up to a capacity of 3 tons are employed.

For this class of work, the van has a pair of back doors or a roller shutter, whilst many of the larger bodies also have facilities for side loading. As the load is usually carried in large bapkets, there are seldom racks

or shelving inside the body. .

The laundry van for house-tohouse collection carries many different sizes of parcel and bundle, with, perhaps, a few hampers. From the loading standpoint, it is an advantage if the majorityof the customers be able to use strong cardboard boxes with well-pattern, liftoff lids. These boxes have a variable capacity, owing to the shape of the lid.

A van which delivers a miscellaneous assortment of parcels should have some interior equipment, so that any parcel ii quickly found and the best use is made of the space available. It is an advantage, therefore, if there be one or two shelves for the lighter packages. These shelves are arranged along each side of the body, or across the front.

If entry be required through the partition behind the driver's seat, the near-side shelf is shortened, so that there is sufficient gangway. On the other hand, if entry be only at the rear, two shelves, either fixed or removable, may be fitted across the body behind the partition.

When the parcels are chiefly small .ones, there is more side shelving and B36 the van has two shelves on each side, which are divided by transverse partitions extending from the floor to the roof. Standing headroom, good natural lighting and ventilation are afforded by a clerestory roof. Weight

is saved by making both shelves and partitions of spaced slats.

The central gangway between the partitioned shelving is accessible either from the back of the van, or through the driver's compartment. The partition opening has a door sliding behind the'partition at the floor or seat-board level. As an alternative, a roller shutter may give access through the partition.

If the driver has an assistant, he is accommodated on that portion of the seat which hinges upwards towards the off side. It has its own folding back rest and the leg automatically folds under with the lifting of the seat.

Another method of equipping a laundry van, which does not add unduly to the weight, consists of dividing the body in the centre with a transverse partition. This is placed at a pillar position and there are two intermediate lightweight standards which support seven or eight laori...zontal battens..

In front of the partition there is a e mid-way shelf of skeleton construction. This front :compartment is accessible from each side of the van by means of a roller shutter. Behind the partition the van has side panels of alit-. minium, and • at the back there is a dwarf tailboard with a roller shutter above

• it.

The rear compartment and the lower. part of the

• front one are intended for the hampers and heavier packages, and the front shelf for the lighter parcels. The roof has a boarded surround for empties, or an emergency load.

The van may also be designed to caMbine foil access on each side and at the rear, with varying amounts of shelving, or an unobstructed interior. In this instance, there is only one central side pillar, which, with the front and rear corner pillars, is strongly plated in order to ensure , rigidity, with a, minimum amount of side framework.

The body has a mid-way shelf which extends for the full length and width of the loading portion. This " deck " consists of spaced boards held together by battens on the underside and made up as front and rear units.

Each floor unit is supported by angle irons, which are fastened to the inside of the rails running all around the loading portion immediately inside the pillars. There is also, at the same height, a cross-rail with an angle iron on each side of it and connecting the two centre pillars. • There are, 'therefore, mid-way between the floor and the roof, two _rectangles of angle iron, each supporting a removable shelf assembly. For convenience of dismounting, the assembly may be made up in smaller units than those described, whilst for small vans the battens may be dispensed with and loose boards. em ployed, which may be spaced by means of distance pieces fixed to the angle irons.

The body with. the removable shelving has hinged sides below the shelving and roller shutters above it, with a similar arrangement at the back. The hinged sides shut not only between the pillars, but also against the middle rail. Advantage is taken of the position of this rail to simplify the fastening of the hinged sides,

As a rule, a hinged side has to be secured at each end, but as there is a rail the full width of the opening, this is utilized for a single central fastening. This may consist of a slotted stud, which registers with a hole in the hinged side and is secured with a pin, or the hinged side may have a slam or budget lock and be fastened in the same manner as a door. If a. lock he fitted, the middle rail is flush with the pillars and the hinged side shuts under it.

It may be considered that a side locked in this way is more liable to fly open than is a door on a vertical hinge line, -but as the rail supports a shelf, the rail will tend to bend downwards slightly in the centre and thus exert pressure at the lock bearing.

When both the roller shutter and hinged side have central fastenings, these are designed so that, when operated, one fastening does not foul the other. To simplify matters, each fastening is sufficiently off-set on each side of the centre, so as to provide a working clearance.