Pneumatic Tires for Motorbuses.

Page 4

Page 5

Page 6

If you've noticed an error in this article please click here to report it so we can fix it.

Although the title of this article may appear fanciful in its appl.cation to double-deckers, the author deals interestingly with a suggested method of employing pneumatics to carry heivier loads than those to which we

are accustorned.—Ed

By Laird Nuttall.

Now that the.•dam.age to our main roads and the very considerable sums of money that arra being devoted to their upkeep are becoming problems of national importance, it is advisable thoroughly to consider any new line of thought which may point the way to improved conditions. More thought should, in the author's opinion he given, for instance, to the type of tire that is being used on heavy motor There is no doubt that motor vehicles of four tons and upwards, fitted with solid tires, are responsible for much of the rapid disintegration of some roads, however unsuitable many of the latter may :ae.

In the presentearticle the waiter has endeavoueed to show that a solution to much of the road-construction difficulty may perhaps-. be secured by equippnog heavy vehicles, such as motorouses, with pneumatics.

To the average man in the street the suggestion of equipping such vehicles—weighing over five tons gross —appears to be a problem bristling with sdilliculties. Visions of punctures, burst tires and all the eeils that are known to pneumatic tires, magnified a hundred-fold, present themselves to his mind, and he is likely to regaed the idea in much the same :manner as the earlier motorists looked upon M. Andre Michelin's endeavour to equip motorcars with tires of the pneumatic variety. Yet there is no limit to the weight that pneumatic tires should be able to support. The writer has endeavoured to show that with properly-constructed pneumatic tires there is no more reason why the motorbus thus shed should not be as familiar a sight in our street-s as is the pneumatictired taxicab.

Action of Solid Tires. • To the observant individual the Pact of solid tires wearing down several inches in the course of a few months' running should be sufficient to convince him that the we-ar cannot have been on the tire alone., but that the road must have suffered in a like manner. The cause of this rapid wear is not difficult to see.

Let us examine briefly the action of the solid tire and its effect on both tire and road. We will assume a motorbus fully loaded weighs six tons, and that each back wheel is supporting a load of two tons. If we estimate that this weight is distributed over a bearing surface of 20 sq. ins, of tire per wheel, wefind that eacn sq. in. is sapporting a load of 2 cwt.

If, in the progress of the revolving wheel, an obstacle be encountered which presents a bearing surface of 1 sq. in.—a stray piece of macadam for example—the whole of the weight supported by that wheel—estimated at two tons—is concentrated on to sq in. of bearing surface, with the result that eiti,er the obstacle is crushed to dust, or it is forced either into the road surface or into the tire itself. In like manner, when the wheel encounters a. pet-hole, the -,vhole weight is distributed over the few inches of bearing surface, with the result that the hole becoiner a little larger under the succession of bloss .s that it has to withstand. To this, of course, must be added the increased force of the blow due to the momenttun of the vehicle, from which it will be seen that the impact with which each square inch of bearing surface strikes an obstack—a pot-hole, for example—is a tremendous one, and one that would easily account for the rapid destruction of the road and also for the rapid wearing down of the tire.

Solid Tires versus Pneumatics.

Let us compare the action of the pneumatic tire with that of the solid and consider the amount of destruction the pneumatic tire leaves in its wake. Let us assume that. we are about to inflate a pneumatic tire fitted to a vehicle the weight of which we will estimate at two tons. Assuming that the weight of the vehicle be divided equally between the four wheels, then in inflating one of the tires we are required to lift a weight of half-a-ton. After a few strokes of the pump, we find that the rim of the wheel just clears the ground by the fraction of an inch, and the actual weight of the ear is off the ground. Let us cease pumping for a moment and examine the state of affairs. We have a pressure in the tire of, say, 15 lb. per sq. in. and the tire is spread over a bearing surface of 75 sq. ins., i.e., those number of sq. ins, which, multiplied by the pressure in the tire, equals the load. It will be seen that, although the weight of the car to be supported is half-a-ton, the pressure on each sq. in. of road surface is but 15 lb.

We continue our operation of inflation until we

nave a pressure in the tire of 60 lb. per sq. in. The rim of the wheel has now been lifted further from the ground, the bearing surface of the tire in contact

ith the ground being now but, 18 sq. ins., and the

essure on each sq. in. of road is 60 lb.

If we now put an extra load on the tire and increase the weight to, say, two tons (tile weight on out motorbus wheel), the tire will yield under the weight until those necessary number of inches come in contact with the road that will support the load. :Neglecting for a moment the increase of air pressure in the tire, due to the squeezing of the air into a smaller space, we find that. the pressure on each sq. in. of the road surface is still only 60 lb. It will be seen therefore that, no matter what the weight of the vehicle to be supported, the weight or pressure on each sq. in: of the ground is whatever the air pressure per sq. m. happens to be in the tire.

Compare this result with the solid tire fitted to a motorbus. Whilst we find that each inch in tlw case of the solid tire is pressing on the ground with at hast 2 cwt., the pneumatic tire in our ease only exerts a pressure of 60 lb. As to the question of momentum, whilst, the impact of the solid tire on each sq. in. is enormously increased with the speed cc the vehicle, in the case of the pneumatic tire the impact is brought to a minimum, for if we assume that the cover of a pneumatic tire possesses no stiffness whatever, and that the tire be inflated to 60 lb. pressure per sq. in., the tire would only strike an obstacle with a 60 lb. per sq. in. force, no ,matter what the speed of the vehicle, for, directly the force of the blow exceeded this amount, the obstacle would hr absorbed into the tire.

This fact helps to account for the enormous advantages that the pneumatic tire possesses over any other form of tire and explains why the pneumatic tire offers less resistance to traction, its advantages being more apparent the greater the speed.

From the foregoing comparison it will be seen that the actions of the solid and pneumatic tires are totally different. Whilst the former wears down several inches during its life, with a corresponding wearing of the roads, the pneumatic tire is comparatively light on the tread, and consequently light on the roads, quite irrespective of the load that the tire (or rather the pressure of air contained in the tire) is supporting.

Why the Pneumatic Tire Has Been Limited.

Up to the present the pneumatic tire has been limited-in its action, only loads of up to, roughly, a ton per wheel being considered practicable, and even then pneumatic tires of the twin variety have had to he used. Users of vehicles above this weight have had to resort to tires of the solid variety with their admitted lack oi resilience and other disadvantages.

Naturally, it will be asked, if pneumatic tires fitted to heavy vehicles are only subjected to the same external wear as when fitted to a light vehicle, why should the pneumatic tire, as at present constructed, be limited as to the weight it can successfully support? The reply to such a question is that it is not the damage from external wear, but the damage from internal strain that, limits the weight that can be supported by a pneumatic.

To make this statement. clear we will assume that a vehicle runs over an ordinary tennis ball. It is obvious that the ball will burst under the weight of the vehicle. Not that the fabric of the tennis ball may not be strong enough to support the weight under certain conditions, but simply because the air contained in the ball is squeezed into a smaller compass under the weight, with the result that the pressure of air is increased until the fabric of the ball is unable to withstand the strain and the ball bursts.

Here is a good example of internal strain and its

effect on the casing that contains the air. It should ba noted that no external damage has effected the burst, the weight of the vehicle has had no direct bursting action, the sole cause being due to the in. creased pressure of air in the ball and the inability of, the casing to withstand the strain.

Recognizing the action that is responsible for the bursting of the tennis ball, let us compare its action with the action that prevails in the case of tiring a heavy vehicle with pneumatic tires that are much too small to carry the load, as would be the case if motorbuses were shod with ordinary pneumatic tires.

We have seen from the bursting of the tennis ball, that the burst is caused by the compression of the air content. The lighter the vehicle the less the compression and consequently the less likelihood of the ter. nis ball's, bursting. So in the case of heavy vehicles shod with pneumatic tires, we find that the continu,1 flattening of the tire (due to rough roads and also to the momentum of the vehicle), to which the th e is subjected, causes the air constantly to be squeezed into a smaller space with exactly the same result as in the case of the bursting of the tennis ball—in a modified form and eventually the tire bursts, What Happens Inside the Tube.

As the function of a pneumatic tire is its give-andtake action when travezsiug uneven ground, thus providing ease of running, it is obvious that the air pressure contained in it is always a varying one. If we take the case of an 810 mm. by 90 mm. tire and assume that the air contained in it is squeezed into 99-100ths of its previous volume, or, in other words, if the air now occupies 495 cubic ins, instead of 500 as originally, the pressure, initially at, say, 80 lb. per sq. in., is now raised to 80.8 lb., showing a rise of 0.8 lb. on every sq. in. of tire. Estimating the number of sq. ins, in the walls of an 810 mm. by 90 min. tire as 1000, we get a total increased strain on the tire of 800 lb.

The same tires fitted to a lighter vehicle would not be subjected to this bursting strain to the same extent owing to the compression of the air being more modified. It would appear then that the factor that prevents heavy vehicles being shod with pneumatic tires is not so much the actual weight of the vehicle as the amount of internal strain that the weight brings to bear upon the tire. So that if we could keep the internal strain on the tire the same in the case of the heavy as in the case of the lighter vehicle, there would seem to be no reason why the tires on the heavy vehicle should burst any sooner than those fitted to the lighter.

Imagine Tennis Balls Strung Together.

Let us assume that we have a tire composed of a series of tennis balls and further that all of the balls, instead of working independently of each other, are connected together by means of tubes, thereby allowing a free passage of the air throughout the whole

series. If we now move the vehicle through one revolution, we find that, as each ball comes in contact with the ground, instead of its bursting (as would be the case if the balls were independent of each other), it is merely flattened and will regain its spherical shape directly the weight of the vehicle has passed to the next ball, and so on.

It is obvious that as each ball is called upon to withstand the load, the air in it is forced from the ball through the connecting tubes and is distributed throughout the whole of the balls. By this means the strain is distributed—the top ball taking quiteas much of the strain as the others—the result being that the strain on each ball is minimized. It is clear also that the greater the number of balls the less the strain on each, and that the same result will obtain if each Pall be connected to an air chamber.

Compare this action with the single tennis ball, and we find that, although the balls in both i cases possessed casings of equal strength and were subjected to the same weight, the result shows that the ball connected up to its neighbour and having a larger cape

city of air at its disposal for compression passes through the ordeal untouched, whereas the ball possessing only a very limited air capacity succumbs under the weight. The percentage increase of pressure is less, the greater the air volume available.

Su in the case of pneumatic tires we find exactly the same action prevailing. If a heavy vehicle be shod with tires that are much too small to withstand the load, we are in the same position as in the case of the single tennis ball, with the result that the tire will burst. In motorcar practice we find that, as we Increase the weight of the car, SO we must correspondingly increase in size of tire, i.e., tires possessing a larger capacity of air. Not that the casing of the tires need necessarily be of stronger material because of the greater load, but simply because the internal strain is minimized, due to the increased volume of air in the larger tires, in exactly the same manner as when we coupled up our tennis balls. From the above argument it would appear that the important factor that determines whether the casing of a pneumatic tire—or tennis ballshall withstand the weight, depends not upon the actual weight of the vehicle but upon the volume of air at the tire's disposal, and that any weight can be taken provided the air volume is proportionate.

It is obvious that there must be a limit in size in which pneumatic tires may be constructed, and therefore there must be a limit to the amount of air that they may contain, but when we remember the experiment of our burst tennis ball and the means that we adopted to prevent its bursting, viz., by connecting it up to a series of balls, it must be clear that this same method will bold as well in the prevention of tires bursting. Bearing this inference in mind then, it follows that if we tire heavy vehicles with ordinary pneumatics and connect the tires up to an extra air chamber by means of air passages we are in the same position as when we prevented our tennis ball from bursting by connecting it up to a series of balls.

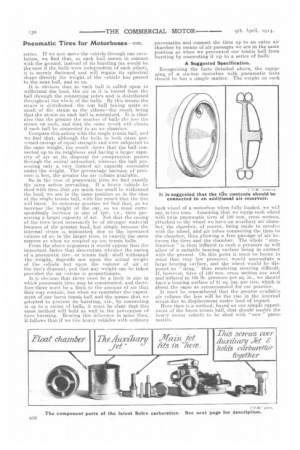

A Suggested Specification.

Recognizing the facts detailed above, the equipping of a six-ton motorbus 1.44th pneumatic tires should be but a simple matter. The weight on each back wheel of a motorbus when fully loaded, we will say, is two tons. Assuming that we equip each wheel with twin pneumatic tires of 120 mm, cross section, attached to the wheel we have an auxiliary air chamber, the chamber, of course, being made to revolve with the wheel, and air tubes connecting the tires to the chamber, thus allowing a free passage of air between the tires and the chamber. The whole " combination" is then inflated to such a pressure as will allow of a suitable bearing surface being in contact with the ground. On this point it must be borne in mind that very low pressures would necessitate a large bearing surface, and the wheel would be disposed to" drag," thus rendering steering difficult. if, however, tires of 120 mm. cross section are used and inflated to 105 lb. pressure per sq. in., we should have a bearing surface of 21 sq. ins, per tire, which is about the same as recommended for car practice.

It must be. remembered that the greater available air volume the less will be the rise in the internal strain due to displacement under load of impact. Here then is a method, based on our simple experiment of the burst tennis ball, that should enable the heavy motor vehicle to be shod with "new " pneumatics.