Eom Drivers &Mechanics TEN SHILLINGS WEEKLY is paid for the

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Send us an account of any sfeeita incident of your work or experience. If suitable, we will edit your notes, suPPly a sketch when required, and i'my you for everything published. Mention your employer's name, in confidence, as evidence of good faith. Address to The Editor, THE COMMERCIAL MOTOR, Rosebery Avenue, London, E.C.

Light Up Your Lamps At – 7..13 on Thursday ; 7..15 on Friday ; 7.46 on Saturday; 7.50 on Monday ; 7.52 on Tuesday ; 7.53 on Wednesday.

A Garage-made Crankshaft.

[1472] " H.111." (West Bromwich) writes :—" It is not often that a repair shop is called upon to perform a task like the one which I am about to describe.

A crankshaft made from scrap steel.

A lorry which we have been running for some years had the misfortune to break its crankshaft, and being an old machine, built by a firm Which has shice become insolvent, we were unable to obtain a new crankshaft from a certain manufacturer without several weeks' delay. I therefore decided to make one myself.

"I obtained a steel shaft of diameter and length approximately equal to the maximum sizes of the broken crankshaft., it had been part of a marine engine. To make the shaft, the following operations were carried cut. I enclose a sketch [Vt, e have had this redrawn.—En.], showing the shaft in its dif. ferent stages of manufacture.

• " The first thing I did was to rough-turn the exch. The shaft was then placed in a shaping machine and cut away on two sides to the width of the crank webs. The journals and webs were marked off on one of the faces, and holes were drilled where it was necessary to remove superfluous metal, the metal between the webs being then sawn down to the level of these holes, andas they were drilled. closely together it was a simple matter to knock the pieces out by the aid of a steel drift.

" The crankpin centres were afterwards accurately marked out., and the crank pins themselves turned in a lathe. The shaft was again placed between the lathe centres and the journals finally trued up to size. The total time taken for making this replacement was something like nine days, and the vehicle itself was on the road again within a fortnight. "Sometimes, by a little bit of scheming and a few good tools, jobs which at first sight appear to be almost impossible can be overcome, and thus time and money saved."

E2 Another Rig for Relining Connecting-rod Brasses [1473] " WED." (Ashbourne) writes:—'' As a regular reader of your paper, I look forward with great interest to the weekly collection of notes contained in your 'D. and M.' pages, and from them have extracted quite an amount of valuable 'information. In return I submit a tip which might prove useful to those of your readers who have to undertake the re-metalling of bearings.

" I recently had to reline a number of big ends, and the job being urgent, there was not sufficient time for me to make a proper rig for doing so. I, however, got out of the difficulty in a very satisfactory manner by the use of it drilling machine. "I first prepared the brasses in the ordinary way by running out the old metal, cleaning and tinning them. I then took the connecting-red, plugged up its oil holes with wood, and placed the prepared brasses in position, fitting a piece of sheet asbestos, a little thicker than the saw which was to be used for separating the halves, between. them. I then placed the big end of the connecting-rod on a piece of sheet asbestos, which was laid on the table of the drilling machine. " The drill-chuck, whk:h was of the flat-face type, was brought down to the necessary height, and two pieces of wood were fitted between it and the big end, the drilling-machine spindle was then screwed down, and thus the connecting-red was held firmly in position. " :In order to prevent the brasses being filled up solid, it was necessary to use a rna.ndrel, and this I held in position by means of a spiral spring placed between it and theSbottam of the chuck.

" If a large number of brasses are to be re-lined, it would perhaps be better to taper this mandrel, in order to allow for its easy removal from the white metal. On testing the arrangement, I found that it was very satisfactory, and quite easy to manipulate." Cylinder Clealing by Oxygen Simplified.

The sender of the following communication has been awarded the 10s. prize this week.

[i,174]" J.N." (New York) writes :—" It is my somewhat unpleasant duty to remove the acemmilation of carbon from the combustion chambers and pistons of engines which we have in for repair purposes. -Until lately this work was accomplished by removing the cylinders and chipping or see-aping off the deposit. A saort time ago, however, I witnessed, at another garage, a mechanic cleaning the cylinders and pistons of a six-cylinder engine by means of the oxygen pro2,eSS, and was very numb impressed by the rapidity with which he accomplished the operation. " As the shop where I am employed is only a small one, we could hardly afford a complete oxygen ap pal atu s. However, after thinking matters osasr, I

managed to make a small oxygen producer, about which a few notes may be appreciated by your

-readers. I enclose a sketch [We have had this redrawn.—End which is almost self-explanatory of the coostructional details of the deyiee.

" The producer consists of a short piece of wroughtiron pipe 11 in. diameter, each end being screwed and

fitted with a cap. One of the caps is drilled and tapped and: has a short piece of brass tubing screwed into the hole whicials fixed in position by a lack nut.

A length of annealed copper tubing was soldered into the end of this brass pipe, the copper tubing being of small diameter and, owing to having heen annealed, quite flexible.

" Held between the brass tube loeknut and the cap is ashort bent piece of iron in. thick arid about -fs' in.

wide. The end of this is wrapped with tape or similar material, to act as a safeguard against burning the hands whilst using the apparatus.

" To use the device two ounces of potassium chlorate, to which a tablespoonful of manganese di oxide has been added, the two being thoroughly mixed together, are introduced into the container formed by the iron pipe, the plain cap being removed for this purpose..

" After screwing this cap tightly in position, the producer is heated by means of a blowpipe, and the

mid of the flexible copper tubing is put into the cornLust:ion chamber of the motor. As soon asthe ingredients are heated sufficiently, oxygen is given off in a steady stream. A lighted match must now be put into the cylinder, and the caked carbon will immediately ignite and will rapidly burn from off the surfaces of the piston arid cylinder.

" For cleaning multiple-cylinder engines, larger quuntitira of the two chemicals can be added. The proportions do not matter to any great extent, as the manganese di-oxide really acts only as a stimulant

In the decomposition of the potassium chlorate. Both chemicals can be obtained from most chemists at a low cost. In using the potassium. chlorate, care should be taken not to let it get into contact with foreign substances. It is essential that the stream of oxygen should be well maintained before being lighted!'

Illegal to Use Copper on Acetylene Plants.

We have received the following communication from the secretary of the British Acetylene and Welding Association. It has reference to a home-made device which was put together by our correspondent "Loll." to take the place of the gas bag on an ordinary acety lene-lighting system. It will perhaps be news to many of our readers that the use of copper in connection with an acetylene generator is illegal. The letter is as follows,— " Sir,—My attention has just been drawn to a letter in your issue of the 19th inst., from 'LW

(1462) and I should like to inform your correspondent and readers generally that the use of copper in connection with an acetylene generator is illegal, the Home Office having from the very commencement of the acetylene industry prohibited by Order in Council the use of copper for any part of acetylene apparatus.

"Hoping you will give publicity to this matter. "I am,

"Yours truly, For and on behalf of The British Acetylene " arid Welding Association,

" it0,11ERT YOUNG, Secretary."

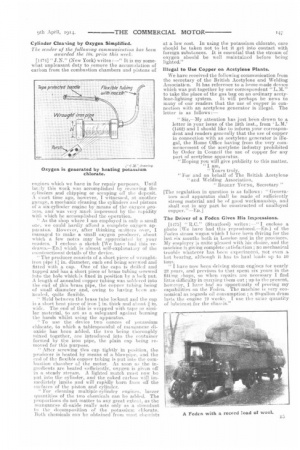

[The regulation in question is as follows : " Generators and apparatus shall be made of sufficiently strung material and be of good workmanship, and shall not in any part be constructed of unalloyed copper."—E».] The Driver of a roden Gives His Impressions.

[1475] "It.e." (Stratford) writes : "I enclose a. photo I.We have had this reproduced.---En.] of the Forlen steam wagon which I have been driving for the last six months both in -London and in the provinces. My employer is quite pleased with his choice, and the machine is giving complete satisfaction ; no mechanical trouble whatever has been experienceo, not even a hot bearing, although it has to haul loads up to 10 tons.

" I have now been driving steam engines for nearly 22 years, and previous to that spent six years in the fitting shops, so when repairs are necessary I find little difficulty in carrying them out ; up to the present, however, I have had no opportunity of proving my capabilities on the Foilen. The machine is very economical as regards oil consumption ; a 20-gallon drum lasts the engine 19 weeks, I use the same quantity or lubricant for the chasis.”