The Design of Modern Steam Tractors.

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

By " Hephcestus."

The recent discussion in this journal, under the heading "Arc Some Tractors Too Powerful'? " is evidence of the considerable interest that is still attached to that class of steam-driven independent " heavy motorcar " which is commonly called the steam tractor. The figures relating to its working costs, which were. published in the " CAL" issue for 26th June last, emphasize its claims to the serious consideration of the haulage contractor.

The object of the pre-sent article is to discuss in some detail the general design of modern steam tractors, pointing out certain special features which require consideration.

Light steam, traction engines were built in this country as far back as 1878, weighing in the neighbourhood of five tons and developing about 20 h.p. They were made under the old Loco Acts of 1861, 1865 and 1878, but the restaictions regarding their operation were so stringent as to render them, of no practical value for road transport wark. With the .advent of the Locos on Highways Act of 1896, flrc demand for this class of eh iele began gradually to increase. 7lakers did not at first follow the lines of the heavier traction englees, but in the early years of this el,ntury this design was again taken up and the present type of tractor developed with the exception that its weight empty, under the limits set by the original Motor Car Acts, had to be under three tons. However, owing to their light weight they could not obtain sufficient adhesion to deat with anything like a. paying load, and the need for a heavier machine was made manifest. The introduction of the Heavy Motor Car Order in 15)05, raising the weight limit to five tons empty, afforded the necessary

It may be useful to recapitulate, at this juncture, the regulations, at present in force, which govern thy construction of the light steam tractor : (1) Weight empty not to exceed 5 tons.

(2) Any axle weight not to exceed 8 tons in working order.

(3) Sum of all axle weights not to exceed 12 tons in 'working order.

(4) Extreme width not to exceed 7 ft. 6 ins.

(5) Springs must be fitted to each axle.

(6) No wheel less than 2 ft. dia., nor less than 5 ins. wide. (7) Width ef tire in inches L

-for 311. dia. rind upwanda. 9+21)

— — below 3 ft. dia. 3

Where L = load on axle in cwts., D – dia. in ft.

(8) Tire smooth or bevelled i in. each side ; if fitted with strikes, aggregate width of space measured across tire parallel to axle not to exceed of tire width.

(9) Speed not to exceed five miles oer hour.

(10) One independent frictional brake fitted, to cause two of its wheels on same axle to be held. I This single requirement was evolved by L.G.B. Order, as the result of our own agitation, about a year ago.---Enj (11) Capable of being reversed.

(12) Anj; moving part capable of being stopped when standing. (13) Constructed so that no smoke or visible vapour is emitted except through tempornry or accidental cause.

F10111 consideration of the weight limit it is evident that this Order was primarily drawn up for motorwagons ; the tractor has been grafted in at a disadvantage owing to its inability to take full advantage of axle weight. However, a movement is on foot to have the law amended so that vehicles shall he regulated by axle weight instead of by tare weight ; also that

tr:zetor may haul two trailers without coming under the traction.

engine laws. If this be accomplished, it will greatly enhance the value of the steam tractor.

How to Get at the Power that is Required.

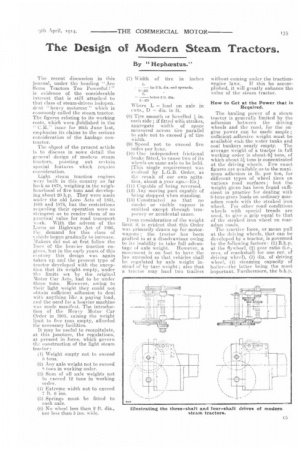

The hauling power of a steam tractor' is generally limited by the adhesion between the driving wheels and the road, for the engine power can be made ample ; suflicient.a.dhesive weight must be available s.ith the water tanks and coal bunkers nearly empty. The average weight of a tractor in full working order is about 6 tons, of which about 5.1 tons is concentrated at the driving wheels. Few exact figures are available as to the maximum adhesion in lb. per ton, for different types of wheel tires on various road surfaces ; but the weight given has been found sufficient in practice for dealing with 6-tons-gross loads on ordinary macadam roads with the straked iron wheel. For other road conditions wheels with special treads are used, to give a grip equal to that of the straked iron wheel on macadam roads

The tractive force, or mean pull at the driving wheels, that can be developed by a tractor, is governed by the following factors ; (1) B.h.p. at the flywheel, (2) gear ratio (i.e., revs, of crankshaft for one rev, of driving wheel), (3) dia. of driving wheel, (4) steaming capacity of boiler—the latter being the most important. Furthermore, the b.h.p. is dependent upon siee of cylinders, working steam pressure, cut off and revs. per minute of crankshaft.. The internal friction of the gearing and axles must also be dedeeted in order to arrive at the power available for propulsion, and this may be taken at 25 per cent. for a three-shaft and 30 per cent. for a. four-shaft engine.

Putting these in a rational form : (1) Tractive force in lb.

x 75 x 33,000 x gear ratio

r.p.m. of crankshaft x circumference of

driving wheels.

To find what tractive force is necessary, take the case or a tractor hauling 8 tons gross load (i.e., trailer and load) up an incline. of 1 in 6, which is the maximum effort required ; the total load to be moved will be 14 tons. Experiments carried out to determine the resistance to movement on ordinaryroads have given varied results, but a value of 70 lb. per ton may be taken as a fair maximum figure on ordinary macadam roads.

The total force necessary to draw this load up the incline will be madeup as follows : Force in lb. to overcome road resistance = 14,4 X 70 = 1030 lb. Force in lb. to lift load up incline x2241) – 5506 Therefore the total tractive force = 6530 lb. The b.h.p. necessary to do this can now be found by equation (1): —

.75 x asrga x gear ratio

6530 = r.p.m. x circumference of wheel, 6590 x r.p.m a cirmunference of wneel Or h,h,p, :15a 33,000 x gear rati7'.

Taking the gear ratio at 23 in slow speed, the r.p.m. at 22e and the wheel dia. at 5 ft., whieh are average figures, the necessary b.h.p. for a tractor so constrk!eted is as follows :— 6530 x 225 x 151 • — = 373 for a three-shaft .75 a 33,000 a 25

engine ; this power must be aeyelopea at the r. p.m. stated.

A road trial with the machine is the only exact way in which its capabilities can be measured, but the above formula will give a good idea whether a tractor has sufficient power or whether it is overpowered.

The 37.3 blip. must not be taken as a standard value for all tractors, for some makers may think it better to use a small gear ratio and run the engine as a slower speed to reduce the wear and tear of the motion work ; in that case the b.h.p. would be greater. Again, most engines arc. fitted with an auxiliary arrangement for supplying live steam to the low-pr'ssure cylinder, and this, of course, iveuld give an increased power for a short period.

c6 What the Boiler's Capacity Must Be.

As previously stated the steaming capacity of the boiler, or its size, is a very important factor, for it limits the continuous power of the engine. If it is too small, apart from reducing the power, the fuel consumption will be large, owing to its continually being forced ; also the repair bill will be heavy and the boiler will be very liable to prime. On the other hand if it is too large its weight becomes excessive, whieli means that more power will be required to haul the same net load, to the detriment of the fuel bill, radius of action 7.nd cost of running. The proper size eau only be determined by practical experiment, but from the results of many trials with various proportions of grate areas, heating surfaces and working pressures, the following may be taken as fair average figures:—

Heating surface 30 toOl sqft. for po lb. pressure Gi.ate area: I to 3,1,sq. ft. for goo3 coal, oil or coke

Welsh coal and coke are the fuels most often used. Oil is an admirable fuel if the cost were not so great, for it requires little attention and can be easily regulated to suit the varying conditions. A special installation of burner and tank is necessary and the extra cost is about £50. Slack coal and wood is practieally never used in this country for tractors.

Fireboxes and Tubes.

The Belpaire boiler is very much in favour at the present time. In. this type the crown of the firebox and the shell top above it are made perfectly fiat, and lb 3 two serfaces eonneeted by screwed stays about 1 in. dia. This is an improvement on the old girder stay type, but screwed stays are always a source of trouble in any boiler. The best type is undoubtedly that in which the firebox crown is corrugated and requires no staying L it is the strongest ma] most efficient. Situated in the hottest part of the boiler, the crown is subjected to most severe expansion and contraction, and apart. from the fact that there are no stays to break, thus movement is sufficient to prevent ilierustation of mud or scale. Also the extra heating surface, obtained by this corrugation, in this hot part, greatly increases the efficiency of the boiler.

The boiler tubes should not be

less than in, dia., and should project through the smokebox tubeplate at least in., to allow for reexpanding should occasion for their removal occur.

The best type of water-gauges are those which close automatically and and instantaneously in the event of a glass breaking ; Klingertype reflex glasses will prove most durable and most eonvenient to the driver.

Injectors, Pumps and Waterlifts.

it is advisable to have tanks of ample capacity,; 130 gallons is usually sufficient for about 15 miles. They should have large manholes and corners of large radii to facilitate cleaning out. The tender should be arranged so that it can be readily detached without taking any axle gear down.

For supplying water to the boiler it is usual to fit a force pump and an injector ; but two injectors are often used. The pump should be driven through gearing, at a slower speed than the crankshaft, and the rate of feed to the boiler should be callable of regulation. It is a great improvement if the plungers have an external guide to relieve the packing of side strain, due to the angularity of the eccentric rod. Independent steam pumps have been used on tractors, but they require careful manipulation, and are liable to get cut of order if the valves are not kept in first-class condition.

The injectors and waterlifter should be supplied with dry steam, preferably from the cylinder dome, regulated by screw-down valves, and the water lifter should be placed so that the suction hose can be coiled without uncoupling.

it is becoming almost standard practice to fit a, water-heater to the pump, and this is a very desirable feature. Apart from the economy gained, it relieves the boiler of undue strains due to cold feed, and much of the sediment in the water is deposited in it. For the latter reason it must be capable of being easily and properly cleaned, the type in which straight brass tubes are employed being the best.

Engine Cylinders and Valve Gears.

Compound cylinders are almost universal now on account of their greater economy ; but some an

must be fitted for supplying live steam to the low-pressure cylinder to facilitate starting. The most convenient position for the valves is on the outer side of each cylinder, but; valves placed on the top and driven by eccentrics between the cranks form a very convenient arrangement.

It is becoming very usual to fix the cylinder to a separate base riveted to the boiler barrel, but this does not affect the user much— for removal of the cylinder is a very rare occurrence. It gives a little extra steam space, but the disadvantage is the increased height of the crank above the boiler.

The valves are usually driven by Stephenson link motion, but radial types of valve gears have occasion ally been employed, The latter possess the advantage of having fewer working parts and therefore less wear and tear, also they ensure a rather better steam distribution in the cylinder; they are perhaps not so well understood by mechanics and drivers.

(7'o k continued.)