M AN is the latest company to jump on the aerodynamic

Page 34

Page 35

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

band wagon with kits for its range of trucks above 7.5 tonnes, launched at the IRTE Telford show. When fully kitted out, vehicles (especially tractive units) take on a different appearance but is that as far as it goes? Do all the efforts in the wind tunnel improve the fuel consumption and journey times or just the looks and the total list price?

Our recent test of Volvo's slippery FH12 (CM 18-24 August) would appear to back up the claims made by the aero-kit camp. Scania has been offering the optional Streamline kit for some time now and almost every truck we road test comes with all the aero trimmings, but does it really make any difference in the long run? Certainly trailblazing operators such as TNT and Excel Logistics thought it was worth investing many thousands of pounds in aerodynamic work on trucks and trailers. But from those heady days we have seen recession and reducing speed limits from 96km/h (60mph) to 90km/h (56km/h) and, if the EU gets its way, down to 851(m/h (53mph).

To sort out which is more slippery, a fully kitted out truck—or the salesman selling it—we ran a series of tests with a MAN 17.322 tractive unit equipped with all the latest wind-cheating goodies and then without.

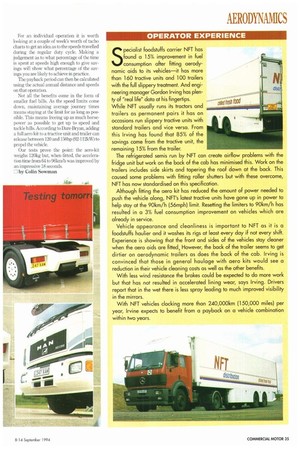

There are many reasons for variations in fuel consumption, the weather, the driver, speed, traffic conditions—all of which make direct comparisons difficult. The greatest benefit from aerodynamic aids will be derived at maximum speed so we This is all you need to knock more than rh, off your fuel bills.

decided to do maximum speed running on Millbrook's two-mile circular track-25 circuits on each test. Travelling in circles cancels out most of the effect of any wind and Millbrook has high banks and trees around much of the banked track. Under present legislation most trucks over 12 tonnes can run at 96km/h. New vehicles since January this year (and over the next 18 months those registered after January 1988) must have their limiters set to 90km/h.

Using an MAN had two advantages: the new aerodynamic kit and a computer-controlled speed limiter on the Bosch fuel pump (to enable resetting between runs). MAN sets the limiters on its trucks to 88km/h (55mph) as standard, so we used that speed and 96km/h (60mph).

TEST PROCEDURE To cover all vehicles we decided to run at both speeds with and without aerodynamic aids. The MAN kit includes a roof spoiler and rear side-extensions to the cab, to ease the air over the front of the trailer. In addition there's a chassis cover catwalk, side skirts for the tractive unit and a rear enclosure.

To speed the process we started with a fully kitted out tractive unit and removed the kit after the first two runs (88 and 96km/h). Once we'd unbolted the aerodynamic aid kit we repeated the first two runs (in reverse order to minimise limiter resetting). All the runs were carried out using CM's own tri-axle Fruehauf test trailer which had its side skirts fitted throughout. We also carried out acceleration runs from 64-96km/h (4060mph) both with and without aem aids.

In general, operators (or usually the dealer) would expect to be fitting aero aids—not taking them off. Fitting out our vehicle would take about eight to 10 hours for the chassis parts and 2.5 hours for the cab kit. Taking it all off took about two hours.

Most attachment to the side of the cab is done on to the guttering but the top of the cab has to be drilled. A frame to support the catwalk is placed over the top of the chassis and the side frames—used to support the side panels—are attached to it. At the back the lights are relocated on to the rear enclosure (eight bolts). While the kit in our tests is manufactured exclusively for MAN, companies such as Kuda and AB Airflow make cab and body kits for all makes of truck.

The aerodynamic aids that we had on our test vehicle would add £3,568 to the list price of our 17.322. This is made up from £1,549 for the adjustable cab air management kit; £1,037 for side skirts (for 3.5m wheebase 4x2); £673 for the rear enclosure and £309 for the chassis cover.

As our vehicle was fitted with a fuel flow meter it was possible to measure the exact amount of fuel used on each run, and the precise distance (81km in the lane we were using). Our aerodynamic tests were conducted over a single day on a dry track with a maximum wind speed of 16krn/h.

Even before we could calculate the fuel economy one thing was obvious—the quality of the speed limiter. Using the MANCATS computer the limiter was reset from 881unJh to 96km/h and back to 88km/h—the test times were repeatable within two seconds over 81km. With your foot to the floor, it was almost impossible to see the speedo needle drop before the whistle from the turbocharger gently picked up.

Not even the late, great Ayrton Senna could put in more consistent lap times. The hard bit was remembering to count the laps.

Having started with all the aerodynamic aids on-board the most noticeable effect of their removal was the increase in wind noise in the cab. We have worked out savings in actual fuel used as percentage savings in mpg is confusing. On that basis, the amount of fuel used by our aero tractor (against a baseline non aero-equipped vehicle) dropped by 12% at 96km/h and just under 9.5% at 88km/h.

Freelance aerodynamic expert Val DareBryan believes that fuel savings can be as high as 17% when equipping some tractor/trailer combinations.

He says cab kits can account for up to 14% and those on the trailer 4%. The difference between Dare-Bryan's expectations and our test comes from two factors: the side skirts remained on the trailer and MANs have an air dam under the front bumper as standard, so it was not removed with the rest of the aero-kit.

Most experts agree that up to about 80km/h most of a truck's power is taken up moving the weight: above that speed more is used in pushing the vehicle through the air. This is confirmed by our tests showing a greater fuel saving at 96km/h. However, that does not mean that there are no savings to be had below that speed. Dare-Bryan, who recently applied his expertise to ERF's latest EC Olympic cab, says that measurable savings start as low as 64km/h (40mph), This is in line with our test results which, when extrapolated, show that the fuel savings could start from 60km/h (38mph).

CM's Scottish route is 50% motorway but even fire-breathing 500hp trucks do not average above 80kin/h on any day! However, even the lower powered tractive units can average over 64km/h (40mph) on all three days.

While we were unable to assess each part of the kit separately, Dare-Bryan has done so in a wind tunnel, A model of a typical base tractive unit and cab would have a coefficient of drag (CD) figure of 0.83. The roof spoiler will take off about 0.28 and is easily the largest single contributor to lowering the drag.

Other items have much less effect. For instance the rear side extensions to the cab and side skirts on the tractive unit only account for a CD reduction of about 0.02. Skirts on the trailer take off about 0.034. However, the last two figures can easily double when the vehicle is heading into a crosswind.

This highlights the difference in a wind tunnel, which usually simulates a truck moving in still air. The benefits of aerodynamic aids are directly related to airflow: which part is from prevailing winds and which vehicle speed is irrelevant. So even at vehicle speeds lower than 64km/h, if you're travelling into a headwind there will still be a beneficial effect. While we have not quantified this during our track tests, during road testing we have seen impg added to fuel consumption running on motorway sections into a headwind.

Calculating savings from fitting aerodynamic aids can only really be done by considering each truck's particular operation. But if our tractive unit clocked up its industry average 120,000km per year fully laden at 88km/h it would consume about 43,850 litres (9,650 gallons) of fuel. By fitting the full aero kit this quantity could be reduced by over 4,100 litres. Taking the price of diesel at the pump at 48p/litre this is represents a saving of around £2,000 per year. Do not forget that if the vehicle was pulling a box or curtainsided trailer, then this level of saving should be good regardless of the state of load.

From seeing his work in operation DareBryan has deduced a rule of thumb that, on average, tractive units doing trunking work will achieve about 75% of the potential fuel savings. An average rigid doing inter-urban multi-drop work will realise about 50% of the potential savings. The difference is the "granny factor"—the number of times the vehicle has to stop for people on pedestrian crossings, traffic lights and so on. For an individual operation it is worth looking at a couple of week's worth of tacho charts to get an idea as to the speeds travelled during the regular duty cycle. Making a judgement as to what percentage of the time is spent at speeds high enough to give savings will show what percentage of the savings you are likely to achieve in practice.

The payback period can then be calculated using the actual annual distance and speeds on that operation.

Not all the benefits come in the form of smaller fuel bills. As the speed limits come down, maintaining average journey times means staying at the limit for as long as possible. This means freeing up as much horsepower as possible to get up to speed and tackle hills. According to Dare-Bryan, adding a full aero kit to a tractive unit and trailer can release between 120 and 150hp (92-112kW) to propel the vehicle.

Our tests prove the point: the aero-kit weighs 120kg but, when fitted, the acceleration time from 64 to 96km/h was improved by an impressive 18 seconds.

by Colin Sowman