Project Superior!

Page 58

Page 59

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

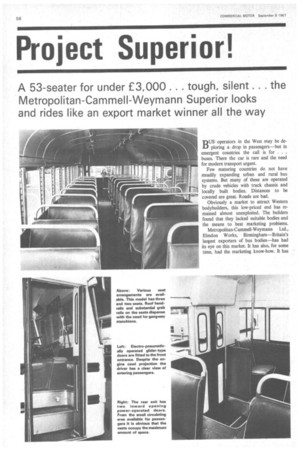

A 53-seater for under £3,000. . . tough, silent. . the Metropolitan-Cammell-Weymann Superior looks and rides like an export market winner all the way

DUS operators in the West may be de

ploring a drop in passengers but in emergent countries the call is for . . . buses. There the car is rare and the need for modern transport urgent.

Few maturing countries do not have steadily expanding urban and rural bus systems. But many of these are operated by crude vehicles with truck chassis and locally built bodies. Distances to be covered are great. Roads are bad.

Obviously a market to attract Western bodybuilders, this low-priced end has remained almost unexploited. The builders found that they lacked suitable bodies and the means to beat marketing problems.

Metropolitan-Cammell-Weymann Ltd., Flmdon Works, Birmingham—Britain's largest exporters of bus bodies—has had its eye on this market. It has also, for some time, had the marketing know-how. It has not had the right-priced vehicle.

Until now. For MCW wisely decided to market an already wen-tried bus body which could be made available in different assembly stages at a highly competitive price.

It chose the Lima, Ohio, Superior Coach Corporation's Superior body design (CommERciAL MOTOR, March 10 and May 5) for its strength, low price and the fact that it can be shipped c.k.d., p.k.d. or assembled.

Moreover—and important in developing countries—it can be assembled by relatively unskilled labour with a minimum of tools and equipment. And the standard materials employed mean that local steel sections can be used.

Then, too, the design is such that the body can be mounted on almost any truck or bus chassis: the kits contain all parts required to adjust the chassis fitment.

The prototype Metropolitan-Superior bus was completed last week and I went to Elmdon to inspect and test-drive it before it left on a demonstration tour of Hungary and Rumania (which wants to assemble the bus there).

MCW built the prototype from US components but British—and/or indigenous --units will gradually be introduced to suit overseas requirements. The chassis is a left-hand-drive Ford R192 with a forwardmounted engine, two-speed rear axle and 9.00-20 tyres.

It may not fit the British conception of styling and layout but the MetropolitanSuperior looks substantial and practical— right for its job. And its price of less than £3,000 including the Ford chassis makes it an attractive and competitive buy as a 53-seater.

It is anticipated that it will be exported principally on Albion, Bedford or Ford chassis—these making the hest combinations.

EXTRA STRENGTH

The body strength lies in the integral construction. All panel sections—such as roof, sides and ends—and the floor are fabricated of zinc-coated steel to prevent corrosion. Extra strength and rigidity is obtained from the die-formed skill-toskirt guard plate. There are massive 10indeep bumpers front and rear.

The all-steel body-3 tons 13cwt 2qris heavier than those of British buses of the same size. The complete vehicle weight, with water, fuel and spare wheel is 7 tons lcwt, weight on front and rear axles being 3 tons 12cwt 2qr and 3 tons 8cwt lqr respectively. It can be dispatched in kit form with six major components: sides, roof, ends and floor (which forms part of the packing case).

Carrying 53 seated passengers in a forward vertical-engined bus with 32ft 2in by 8ft box dimensions makes the seating rather tight. This is in the three and two formation, the seats having tubular frames with, surprisingly, spring cushions and rubberized hair squabs; these are upholstered in leather cloth. The floor is covered in lino under the seats and non-slip rubber composition in the gangway.

Front entrance and rear exit is obviously the intention of the door layout, that at the front being a four-leaf folding unit and at the rear a two-leaf door that folds inwards. Both are electro-pneumatically operated by the driver and top and lower halves are glazed.

Headroom is 6ft but this can be raised another 6in by inserting a section of standee windows all round between the body sides and roof.

The 10 full-drop opening windows on each side provide most of the ventilation although there are two flap vents in the front end. Only the onepiece windscreen is curved.

There are 11 internal roof lights with plastic lenses. They are rather small but the illumination appears to be adequate. In typical US style, there are three warning lights at both ends and corner-marker lamps, apart from tail lamps. The total number of lights in the rear is 13, four of which illuminate when braking.

The body wiring is carried in a harness concealed behind moulding above the side windows. For assembly and maintenance it has simple plug and socket connectors. Four light switches and two door switches are located to the left of the driver.

Surprisingly, on the road, the all-steel Metropolitan-Superior is one of the quietest forward-engined buses I have travelled in. Considerable attention has been paid to sound insulation by coating the inside of the panels with absorbent material but it is the lack of engine noise with which I am most impressed.

This is a result of plentiful glass fibre covering the interior of the engine cowl which itself is so large that there is ample room between it and the engine. Unfortunately the cowl protrudes so much into the body that it tends to obstruct the passage from the front door: there is only about 6in clearance between the corner of the cowl and the edge of the seat nearest the door.

EXTRA SAFETY

With its high seating capacity it would not be easy to work on urban services: removal of the front pair of seats would certainly facilitate the movement of passengers.

Each set of doors has a single stanchion which seems adequate for safety but MCW proposes to fit an additional stanchion alongside each door.

There are roof handrails running the full length and each seat has a massive tubular top grab rail. The seats themselves are comfortable despite the lack of legroom.

GOOD VISIBILITY

The driver's seat is also satisfactory with its two-way adjustment and it affords good forward visibility.

The Metropolitan-Superior is pleasant to handle, especially with the aid of two well-positioned external mirrors and the widest internal tinted mirror I have used. It certainly had the simplest of instrument panels—merely the speedometer and an air pressure gauge.

There are no luggage racks inside the bus (luggage is meant to be carried in the large roof rack reached by a ladder at the rear). At the front there is a single destination box (blinds and gear are optional).

ATTRACTIVE FINISH

Although the bus is strictly functional, MCW has given it an attractive white and black exterior finish while the interior is painted in grey and green with plastic enamel.

I feel this bus will make a strong impression on overseas operators. The early arrangements for manufacture in Rumania assure the project a good start. And the reputations abroad of Superior and MCW will undoubtedly act as a spur. But it is the price that should tip the scales in its favour against any competition.