MAKING BEST USE OF_ THE FORD.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, Which will Appeal to the Owner, Driver and Repairer.

IN THIS series of hints concern_Ling the Ford light chassis and ton truck, we endeavour to deal with the subjea from every viewpoint, so that the advice will appeal to the owner, driver, maintenance engineer or mechanic.

We shall welcome for inclusion among the hints those which have proved of value to individual users, and will make suitable remuneration for any which are published.

338.—Keeping the Fan Belt in Position.

Fan belts sometimes develop a habit of slipping off their pulleys, and the sketch which we reproduce shows a simple device by which this can be prevented. It consists of a short length of j-in. by i-in, iron or mild steel bent

as shown, and with a hole drilled in one end to fit over the bolt holding the timer arm to the breather. If put in front of this arm it will not interfere -with its working, and at the same time will give the fan belt plenty of room.

Care must be taken that the end of the arm does not touch the fan.

339.—Servicing Ford Batteries.

A useful scheme has been inaugurated by C. A. Vandervell and Co., Ltd., by which all makes of Ford batteries will be repaired and guaranteed at a cost of 25s. 6d. each, where the outer wood crate, the ebonite jars, lids and vents are in a condition to be used again. The price includes acid and initial charging and putting the battery into condition for immediate use. The work is carried out by the C.A.V. Battery Service Station, 90, High Street, Camden Town, N.W.1.

340.—Strengthening the Springs of the Ton Truck.

In some cases where the ton truck has been employed for heavy work over c36

rough roads the springs have been found to be somewhat too flexible, in which case a great improvement can be made

by duplicating, the leaf next to that at the bottom. This will entail very little expense and he found most effective, particularly where a vehicle constantly carries full loads.

341,—Alterations in the Standard British-built Chassis.

Several modifications have recently been made in the standard van and truck chassis. The steering gears now have a ratio of 5 to 1, which makes steering much easier; but an improvement of much greater importance, from the point of view of maintenance, is the new type of transmission band, each band now being made with a detachable lug at one side to allow the band to be withdrawn and replaced through the door of the transmission cover.

The lug is held in place by studs in special slots, the shoulder of the lug snapping over the end of the brake band, thus holding it securely in place.

To remove the lug it is orilk necessary to insert a tool, made by bending over

the end of a screwdriver for a in., through the end of the lug into the square hole in the end of the brake band. Lifting up the tool then forces the band down and the lug back. After the nuts, washers and springs have been removed from the pedal shafts the reverse and brake pedals are pulled out so far as possible; the bands may then be withdrawn from one side, permitting them to follow close to the cover to prevent distortion.

With the new steering gear goes a new steering wheel, 17 ins. in diameter. It must be pointed out that the pinions used in the new gear are not interchangeable with those on the 4-to-1 type.

The use of side bolts and blocks for the crankcase arms on the trucks has been discontinued. This permits the mounting of the eng,Ine to be more flexible and reduces the chances of cracking the crankcase arms.

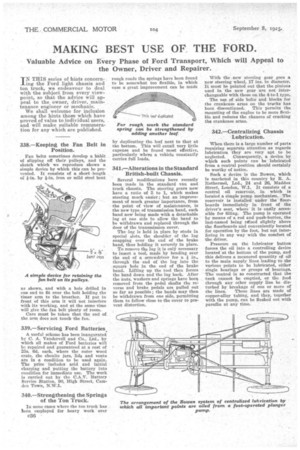

342.—Centralizing Chassis Lubrication.

When there is a large number of parts requiring separate attention as regards lubrication they are very apt to be

neglected. Consequently, a device by which such points can be lubricated from a central position should certainly be worthy of notice.

Such a _device is the Bowen, which is marketed in this country by R. A. nothermel, Ltd. 24 and 26, Maddox

Street, London, Ltd., It consists of a central oil reservoir, in which is located a simple pump mechanism. The reservoir is installed under the floorboards immediately in front of the driver's seat, where it is easily accessible for filling. The pump is operated by means of a rod and push-button, the last-named being raised slightly above the floorboards and conveniently located for operation by the foot, but not interfering in any way with the comfort of the driver.

Pressure on the lubricator button forces the oil into a controlling device located at the bottom of the pump, and this delivers a measured quantity of oil to the main supply lines leading to the various points to be lubricated, either single bearings or groups of bearings. The control is so constructed that the tank cannot be emptied, or the feed through any other supply line be disturbed by breakage of one or more of the lines. These lines are made of copper-alloy tubing, and they, together with the pump, can be flushed out with paraffin at any time.