OILING TN WHEELS

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

Silkolene makes top quality oils and lubricants, selling more than half of its lubricant output to the haulage industry. How does the company run its own haulage operation —and how has it saved 35% of its unit costs over the past three years?

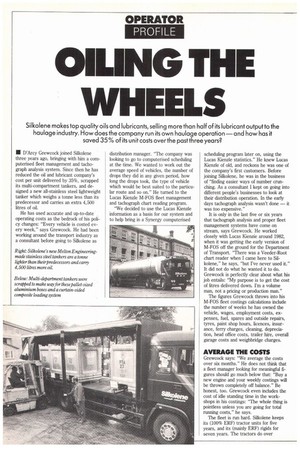

• D'Arcy Grewcock joined Silkolene three years ago, bringing with him a computerised fleet management and tachograph analysis system. Since then he has reduced the oil and lubricant company's cost per unit delivered by 35%, scrapped its multi-compartment tankers, and designed a new all-stainless steel lightweight tanker which weighs a tonne less than its predecessor and carries an extra 4,500 litres of oil.

He has used accurate and up-to-date operating costs as the bedrock of his policy changes: "Every vehicle is costed every week," says Grewcock. He had been working around the transport industry as a consultant before going to Silkolene as distribution manager. "The company was looking to go to computerised scheduling at the time. We wanted to work out the average speed of vehicles, the number of drops they did in any given period, how long the drops took, the type of vehicle which would be best suited to the particular route and so on." He turned to the Lucas Kienzle M-FOS fleet management and tachograph chart reading program.

"We decided to use the Lucas Kienzle information as a basis for our system and to help bring in a Synergy computerised scheduling program later on, using the Lucas Kienzle statistics." He knew Lucas Kienzle of old, and reckons he was one of the company's first customers. Before joining Silkolene, he was in the business of "finding easier ways of number crunching. As a consultant I kept on going into different people's businesses to look at their distribution operation. In the early days tachograph analysis wasn't done — it was too expensive."

It is only in the last five or six years that tachograph analysis and proper fleet management systems have come on stream, says Grewcock. He worked closely with Lucas Kienzie around 1982, when it was getting the early version of M-FOS off the ground for the Department of Transport. "There was a Veeder-Root chart reader when I came here to Silkolene," he says, "but I've never used it." It did not do what he wanted it to do. Grewcock is perfectly clear about what his job entails: "My purpose is to get the cost of litres delivered down. I'm a volume man, not a pricing or production man."

The figures Grewcock throws into his M-FOS fleet costings calculations include the number of weeks he has owned the vehicle, wages, employment costs, expenses, fuel, spares and outside repairs, tyres, paint shop hours, licences, insurance, ferry charges, cleaning, depreciation, head office costs, trailer hire, overall garage costs and weighbridge charges.

AVERAGE THE COSTS

Grewcock says: "We average the costs over six months." He does not think that a fleet manager looking for meaningful figures should go much below that: "Buy a new engine and your weekly costings will be thrown completely off balance." Be honest, too. Grewcock even includes the cost of idle standing time in the workshops in his costings: "The whole thing is pointless unless you are going for total running costs," he says.

The fleet is run hard. Silkolene keeps its (100% ERF) tractor units for five years, and its (mainly ERF) rigids for seven years. The tractors do over 112,000km a year, and the rigids over 88,000Icm. Grewcock has nine tractor units and 15 trailers in the artic fleet and has his running costs down to about 61.5p per kilometre (98.94p per mile). They run at 38 tonnes GVW with a 3+2 configuration.

Elsewhere in the fleet are six 24-tonne rigids with composite bodies, two 24tonne GVW tankers, six 16-tonne GVW tankers and five 7.5-tonne rigids. The 24tonne composites and the 7.5-tonne rigids have curtain-sided bodies and are used to carry oil and lubricants in pallet-sized aluminium boxes. Grewcock has found these composite loads far more economical, especially for transporting low-volume, high-value loads. He has got rid of nearly all of Silkolene's old multi-compartment tankers.

RUNNING COSTS

"The artics usually run full delivering to big manufacturers, and the 24-tanners are used for redeliveries," says Grewcock. Having used the Lucas Kienzle system to get running costs as accurate as possible, he went on to develop a fleet management system from the same M-FOS package. "We had several meetings here with Lucas Kienzle to decide the parameters," says Grewcock. "I really wanted to get at the cost-per-litre delivered."

It was decided to include the following figures in this analysis: average speed, the time spent at each drop, the number of drops, driver costs, fuel costs, the volume delivered, the volume collected and the maintenance cost. The cost of the factory weighbridge, the yard shunter and the site forklifts are added in too.

Grey areas should also be considered, says Grewcock, such as the idle time when changing tachograph charts, or the fact that each truck only runs for 50 weeks of the year.

As Grewcock looked through the operating costs, he encouraged Silkolene's drivers to transfer from 16-tonners to the new 24-tonne composites. "One driver's production rate went up by 76% just as a result of switching over," he says.

Most of the time Silkolene is six or seven weeks behind on its costings. Hours law information can now be added into the M-FOS package and "the next move", says Grewcock, "is going to be look at weekly castings. We are going to have to put the information on to an IBM first, however". The M-FOS unit at Silkolene runs on an old fashioned Sirius computer, the system originally recommended by Lucas. When Silkolene moves over to an IBM hard disk system it will be able to process information much faster.

There is a sort of in-bred fear among transport managers about getting the sort of information M-FOS can produce, says Grewcock: "I came across a lot of transport managers, when I was doing consultancy work, who were frightened to use this sort of system. Half of them didn't want to know how inefficient they were, and the other half didn't want to have to confront their drivers. I remember one large company told the unions and the convenors said that the figures were not the truth." He worked with one large nationalised industry which ended up by paying him off — "they threw me out", he says. "They were running trucks from Manchester to Haywards Heath in Sussex, swapping over at Newport Pagnell. The trucks were often running empty. The managing director wouldn't believe and told me I was bloody dangerous."

IMMEDIATE SOLUTIONS

Grewcock likes the challenge of "sorting things out", as he puts it, and of overcoming problems to which there are no obvious or immediate solutions. The new six-tonne all-stainless steel tanker bodies he has developed are a case in point. Melton Engineering, based near Heckmondwike in West Yorkshire has built the units to Grewcock's specifications. The one-tonne saving in trailer weight and the extra 4,500 litres the units can carry (up from 27,000 litres to 31,500 litres) have "definitely made all the investment in time and money worthwhile", he says.

If Grewcock has one criticism of the Lucas Kienzle package, it is that there is a lack of back-up manuals to help run the system: "Lucas Kienzie has been promising me M-FOS manual for five years now. Their hours law program manual is about ready, but the fleet management manual still seems a long way off," by Geoff Hadwick