There's many a slip

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

A BRAKING SYSTEM defect which in summer might result in nothing more serious than a quickening of the driver's pulse could be disastrous in winter. As the coefficient of friction between the tyres and road surface goes down because of rain, snow or ice, so the chances of an accident caused by under-par brakes must increase. And fewer hours of daylight perhaps combined with reduced visibility due to fog or mist certainly do nothing to make road conditions safer.

It is not difficult, therefore, to argue the case for a maintenance policy which demands that vehicles' braking systems be thoroughly checked and correctly adjusted before the onset of winter.

But air-braking systems have one particular enemy which is at its most harmful during the winter months and so deserves special attention. The enemy is water. It attacks in a number of ways, and manufacturers of air brake equipment have devised numerous means of countering them — some simple, some sophisticated. The one thing that all the devices have in common is that they have to be properly maintained if they are to remain effective.

If moisture is allowed to accum ulate inside an air brake system for any length of time it will cause corrosion and the products of this corrosion can cause air leaks. One of the most common reasons for a leaking foot brake valve for example, is a piece of rust holding a valve off its seat.

More serious though, particularly in winter, is the problem of water vapour condensing inside cool brake pipes and then freezing, with the result that the pipes are partially or completely blocked. This is most likely to happen if the system has loops or dips in its pipework which are exposed to a cold air stream so these should be avoided where possible. Wet tanks and condensers, on the other hand, work most efficiently when

mounted so that they are exposed to cold air.

These components are currently two of the most popular means of dealing with unwanted water, at least for lighter vehicles which are produced in high volumes.

There is no satisfactory way of completely preventing moisture from entering the brake system. Compressed air leaving the compressor is bound to contain some water vapour as well as, probably, some hot oil. The problem can be dealt with in one of two ways, either by expelling the moisture and contaminants or by satisfactorily treating them.

Both Clayton Dewandre and Bendix, Europe's two leading suppliers of air brake compo nents offer a range of equipment to suit both solutions, the degree of sophistication depending on how much the vehicle manufacturer is prepared to spend.

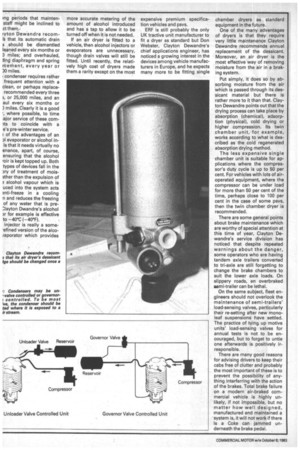

Right at the bottom of the scale is the familiar manualdrain valve which may be either the drain cock type or the tilt drain valve. The advantages of the latter are that its spring return prevents it being left open, and it can be remotely operated by a length of wire.

It is becoming increasingly common for manual drain valves such as this to be replaced by automatic ones which are actuated by pressure fluctuations in the air reservoir.

While these automatic valves do relieve drivers of the chore of draining air reservoirs daily (and only a conscientious few were ever prepared to do that) it can be argued that they make early detection of some braking system malfunctions less likely, simply because they do usually work so well without attention ■ ng periods that mainten staff might be inclined to ct them..

iyton Dewandre recoml's that its automatic drain

s .should be dismantled leaned every six months or

D miles; and overhauled, ling diaphragm and spring 'cement, every year or DO miles.

condenser requires rather frequent attention with a clean, or perhaps replacerecommended every three 3, or 25,000 miles, and an aul every six months or miles. Clearly it is a good where possible, to time ajor service of these cornits to coincide with a e's pre-winter service.

of the advantages of an 31 evaporator or alcohol inis that it needs virtually no

enance, apart, of course, ensuring that the alcohol

,oir is kept topped up. Both types of devices fall in the )ry of treatment of mois)ther than the expulsion of alcohol vapour which is uced into the system acts inti-freeze in a cooling n and reduces the freezing of any water that is preIlayton Dwandre's alcohol )rfor example is effective to —40°C (-40°F).

injector is really a some-efined version of the alco/aporator which provides

more accurate metering of the amount of alcohol introduced and has a tap to allow it to be turned off when it is not needed.

If an air dryer is fitted to a vehicle, then alcohol injectors or evaporators are unnecessary, though drain valves will still be fitted. Until recently, the relatively high cost of dryers made them a rarity except on the most expensive premium specification vehicles and psvs.

ERF is still probably the only UK tractive unit manufacturer to fit a dryer as standard but Don Webster, Clayton Dewandre's chief applications engineer, has noticed a growing interest in the devices among vehicle manufacturers in Europe, and he expects many more to be fitting single chamber dryers as standard equipment in the future.

One of the many advantages of dryers is that they require very little maintenance Clayton Dewandre recommends annual replacement of the dessicant. Moreover, an air dryer is the most effective way of removing moisture from the air in a braking system.

Put simply, it does so by absorbing moisture from the air which is passed through its dessicant material but there is rather more to it than that. Clayton Dewandre points out that the drying process can take place by absorption (chemical), adsorption (physical), cold drying or higher compression. Its twin chamber unit, for example, works according to what is described as the cold regenerated absorption drying method.

The less expensive single chamber unit is suitable for applications where the compressor's duty cycle is up to 50 per cent. For vehicles with lots of airoperated equipment, where the compressor can be under load for more than 50 per cent of the time, perhaps close to 100 per cent in the case of some psvs, then the twin chamber dryer is recommended.

There are some general points about brake maintenance which are worthy of special attention at this time of year, Clayton Dewandre's service division has noticed that despite repeated warnings about the danger, some operators who are having tandem axle trailers converted to tri-axle are still forgetting to change the brake chambers to suit the lower axle loads. On slippery roads, an overbraked semi-trailer can be lethal.

On the same subject, fleet engineers should not overlook the maintenance of semi-trailers' load-sensing valves, particularly their re-setting after new monoleaf suspensions have settled. The practice of tying up motive units' load-sensing valves for annual tests is not to be encouraged, but to forget to untie one afterwards is positively irresponsible.

There are many good reasons for advising drivers to keep their cabs free of clutter and probably the most important of these is to prevent the possibility of anything interferring with the action of the brakes. Total brake failure on a modern air-braked commercial vehicle is highly unlikely, if not impossible, but no matter how well designed, manufactured and maintained a system is, it will not work if there is a Coke can jammed underneath the brake pedal.