Road Test ol igirus-Deutz 6-wheeler

Page 68

Page 69

Page 70

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

By A. J. P. Wilding

AM1 Mech E, MIRTE

IN the past. British vehicle makers have been hampered In their efforts to export to the Continent because they have had to design special models to take account of considerable differences in permitted weights, operating conditions and the like. The same has applied to exports by Continental companies to the UK—to a greater degree if anything, because we were the odd man oul—and little interest has been shown in the UK as a potential market.

Circumstances have, however, changed with the uprating of British weight limits and improvements in our road network so that there is not now so much difference between the requirements for vehicles used in 'the UK and in the rest of Western Europe. Add to this the dissatisfaction which is often expressed nov*adays at long delivery delays— over two years in some cases—and it is easy to see the reasons for the apparent increase in interest shown by overseas vehicle manufacturers in Britain as a prospective market.

This year we have heard news of American companies making preparation to sell here and, as exclusively reported in "The Commercial Motor" of bib. 39, a second make of German heavy commercial vehicle—the Magirus-Deurt —is now obtainable by British operators.

First deliveries of these vehicles will shortly he made by Magirus-Deutz (Concessionaires) Ltd.. the company set up by C. H. and H. L. Blundell, of Folkestone. to do the marketing. A description of the various types that will be available appeared in The Commercial Motor of September 25. and in Qv Vd me issue there was a report of the Frankfurt Show at which tilt cabs were introduced for

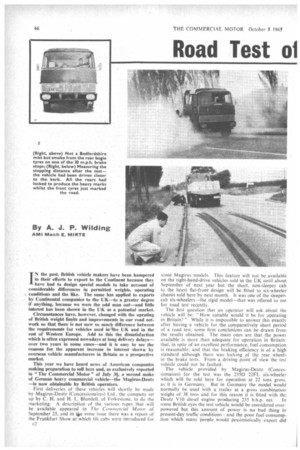

F2 some Magirus models. This feature will not be tt.ailable on the right-hand-drive vehicles sold in the UK until about September of next year but the short, non-sleeper cab to the latest flat-front design will be fitted to six-wheeler chassis sold here by next month. It was one of the sleeper. cab six-wheelers—the rigid model—that was offered to me For road test recently.

The first question that an operator will ask about the vehicle will be: How suitable would it be for operating in Britain? " While it is impossible to answer this exactly after having a vehicle for the comparatively short period of a road test, some firm conchisions can be drawn from the results obtained. The main ones are that the power available is more than adequate for operation in Britain: that, in spite of an excellent performance, fuel consumption is reasonable; and that the braking efficiency is of a high standard although there was locking of the rear wheels in the brake tests. From a driving point of view the test vehicle could not be faulted.

The vehicle provided by Magirus-Deutz (Concessionaires) for the test was the 235D 22FL six-wheeler which will he sold here for operation at 22 tons gross. as it is in Germany. But in Germany the model would normally he used with a trailer at a gross combination ' weight of 38 tons and for this reason it is fitted with the Deutz V 10 diesel engine producing 235 b.h.p. net. In some British eyes the test vehicle would be considered overpowered but this amount of power is no bad thing in present-day traffic conditions and the poor fuel consumption which many 'people would pessimistically expect did

result. A V10 engine is possibly a peculiar animal to ly people's way of thinking but this configuration has used for many years by Deutz. (Only in goods vehicles e the 1963 Frankfurt Show--when the 235D 22FL was )duced—but it had been fitted in military vehicles for e years before this, and industrial and marine versions ! been in operation for a long time also.) 'Ile aspect of the Deutz engine which will be appreciated lot of operators is that it is an air-cooled unit and so imates the problem with water-cooling systems in ter. The air-cooling is provided by an hydraulically en, high-performance fan located in front at the apex of the vee and this directs air through longitudinal passages in each bank to the individual finned cylinders. An important feature of the Deutz design is that there are separate cylinders and heads which can be changed independently of each other. The engine forms a relatively compact unit and on the sleeper-cab vehicle tested it can be accommodated under the seat support pressing and within the length of the cab; on the short cab it will protrude some 18 in. to the rear. Maximum output of the engine is 235 b.h.p. net at 2,300 r.p.m. and maximum net torque is 622 lb. ft. at 1,300 r.p.rn.

Bore and stroke dimensions of the engine are 120 mm. and 140 mm. respectively, giving a capacity of 15.83 litres {9-66 cu. in.) and the engine drives through a single-plate clutch to a ZF AK6-80 six-speed gearbox. An unusual feature in a vehicle of this size is that gear changing is by a steering-col umn-m oun ted lever.

The double-drive rear axles have spiral-bevel and spur double-reduction gearing in the centre for the primary reduction with additional reduction by epicyclic gearing in the hubs. Suspension is by leaf springs all round, the fronts being slipper mounted at the rear end (with steel wearing plates) whilst the single invested-leaf-springs at each side of the rear are carried on top of the pivot brackets and are also slipper mounted, being carried in brackets on top of the axle casings. Each rear axle is located by torque rods, one on each side underneath and a single central one at the top.

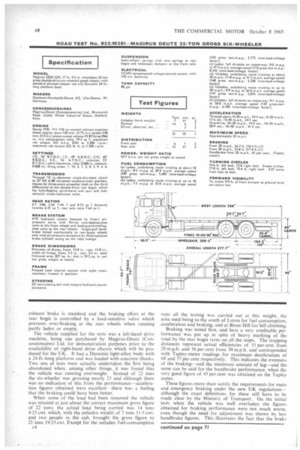

Power-assisted steering is standard, a ZF recirculatingball unit with integral hydraulic assistance being fitted. Braking is by an air-assisted hydraulic system, with the front wheels and rear bogie wheels on separate circuits. Air-pressure assistance to the handbrake is provided by a diaphragm-type chamber acting on the mechanical linkage to the rear bogie. To comply with German law an engine exhaust brake is standard and the braking effort at the rear bogie is controlled by a load-sensitive valve which prevents over-braking at the rear wheels when running partly laden or empty. The vehicle supplied for the tests was a left-hand drive machine, being one purchased by Magirus-Deutz (Concessionaires) Ltd. for demonstration purposes prior to the availability of right-hand drive chassis which will be produced for the UK. It had a Duramin light-alloy body with a 24-ft.-long platform and was loaded with concrete blocks. Two sets of tests were actually undertaken the first being abandoned when, among other things, it was found that the vehicle was running overweight. Instead of 22 tons the six-wheeler was grossing nearly 25 and although there was no indication of this from the performance—acceleration figures obtained were excellent there was a feeling that the braking could have been better. When some of the load had been removed the vehicle was retested at just about the correct maximum gross figure of 22 tons; the actual load being carried was 14 tons 4-25 cwt. which, with the unladen weight of 7 tons 11.5 cwt. and two people in the cab, brought the gross figure to 21 tons 19.25 cwt. Except for the unladen fuel-consumption r.4 runs all the testing was carried out at this weight, the area used being to the south of Luton for fuel consumption, acceleration and braking, and at Bison Hill for hill climbing. Braking was tested first, and here a very creditable performance was put up in spite of heavy marking of the road by the rear bogie tyres on all the stops. The stopping distances represent actual efficiencies of 51 per cent from 20 m.p.h. and 56 per cent from 30 m.p.h. and corresponded with Tapley-meter readings for maximum deceleration of 68 and 77 per cent respectively. This indicates the evenness of the braking—and the minimum amount of lag—and the same can be said for the handbrake performance, when the very good figure of' 45 per cent was obtained on the Tapley meter.

These figures more than satisfy the requirements for main and emergency braking under the new UK regulations— although the exact definitions for these still have to be made clear by the Ministry of Transport. On the initial tests when the vehicle was well overladen the figures obtained for braking performance were not much worse. even though the need for adjustment was shown by low handbrake figures. This illustrates the fact that the brako

1-1 has quite a lot

J

and to allow for slight overloading wear.

celeration tests also carried out 0 the vehicle carryhe extra load and then the figures ned were excelwithout any incli

n that more than lesigned load was ; carried. When Magirus was correctly loaded the figures obtained astonishing, the 17-6 seconds for 0 to 30 m.p.h. igh the gears being better than any 2-tonner previously I by The Commercial Motor and not much different what can be expected from a diesel-engined light van. rect-drive acceleration performance figures included le table were obtained with top gear (overdrive) ged as the rear axle ratio was much lower than one d find on a comparable British vehicle. This meant the transmission layout was more like the normal ;h axle ratio with a direct-top box—the overall ratio lerdrive on the Magirus-Deutz was 5-5 to I and in ;h vehicles of the same type rear-axle ratios are -ally around 6 to 1. As it was, the performance figures p gear were outstanding.

e advantages that would have been obtained by the f a higher rear-axle ratio arc made obvious when coning fuel consumption and if the higher axle ratio that tilable— 6-6 to 1--had been fitted, better figures would been obtained without any appreciable loss in perance. As it is, the consumption figures obtained are acceptable and are comparable with those obtained this class of vehicle on previous tests. I would expect nsumption return of around 9.0 to 10.0 m.p.g. for al types of operation with the vehicle tested and een 10-0 and 11.0 m.p.g. using the higher rear-axle

orway Tests

the motorway tests the high power available at the Is was most beneficial and at no time was it necessary -op a gear on the runs in spite of there being some demanding climbs on the section between the A6 and .6 junctions of M1 where the test took place. Whilst he motorway the maximum speeds in gears were ced and found to be 3, 8, 14, 26, 38 and 55 m.p.h., taking into account a speedometer that read around er cent fast. If the 6 to I rear-axle ratio had been used naximurn speed would have been about 64 m.p.h.

e hill-climbing performance tests at Bison naturally rmed the abundance of power available. A maximumr ascent of the 0-75-mile hill (average gradient 1 in was made in the very fast time of 3 min. 37 sec. minimum speed on the ascent was 8 m.p.h., this ; whilst second gear—the lowest used—was engaged. time spent in second was 1 min. 18-6 sec. ake fade was assessed on a run down the hill in -al with the footbrake applied to restrict the speed to .p.h. At the bottom where the gradient is less, top was engaged and the vehicle driven against the brakes full throttle applied. Total time for the descent was 1. 57 sec., 32 sec. being spent driving against the brakes,

and at the bottom a maximum-pressure brake application from 20 m.p.h..produced a Tapley-meter reading of 57 per cent. As this was not a very great reduction from the best figure obtained on the earlier cold-drum tests, and as the rear wheels still locked it can safely be said that the Magirus six-wheeler will not suffer from fade problems. Although the fade test at Bison is fairly severe the vehicle is designed to be operated in Alpine conditions and one would expect the brakes to be fade-free. On long descents the exhaust brake would save a lot of brake usage and this was tried on Bison, when it was found possible to keep the speed down to a safe limit without applying the wheel brakes.

The steepest section of Bison has a gradient of I in 6.5 and here stop-and-restart tests were carried out. When facing up the slope an easy getaway was made in second gear and, when facing down, effortless restarts in reverse were made. In both positions the handbrake held the vehicle with notches to spare.

Again, because the vehicle has to be capable of travelling over mountain ranges such as the Alps, Bison Hill was not much of a test of the engine air-coolin2. system. It is worth pointing out here that the speed of the engine cooling fan is varied automatically according to the air outlet temperature. This gives the advantage of quick warming up, and a dash-mounted gauge gives an indication of the temperature. For the whole test the needle rested in the centre of the "safe " area and there was no noticeable change during the hill-climb.

Perfect for the Driver

From a driving point of view there is little that one can fault in the Magirus-Deutz design. I found the powerassisted steering very good once the initial feeling of vagueness was overcome, and all the controls were easy and light to use and the brake "feet' was particularly good. I never really mastered the gearchange however, which had not worn off its "newness "; but possibly the main difficulty was the strangeness of changing with the right hand, coupled with a column-change on a vehicle of this size. The Magirus-Deutz driver who came over from Germany especially for the tests made perfect changes and used a rather interesting technique for slowing the engine down with the exhaust brake to make fast upward changes. Comfort and visibility are two other points on which the Magirus design can be praised and this applies to the passengers are well as to the driver, who incidentally has a sprung driving seat. There is plenty of leg room for the passengers and although the passenger seat is planned for two men, three of normal size can be accommodated. The standard of interior trim in the cab is very high and the space available for stowage of papers and the like is more than adequate.

In general, I found the suspension very good indeed both laden and unladen but on certain road surfaces there was a tendency for the front end to bounce rhythmically at speeds around 30 m.p.h. This did not happen at other speeds, or on all road surfaces, and I thought the answer might be that damping of the spring action was required. But telescopic dampers are fitted to the front axle, so maybe an improvement to their design is called for.

Access to the cab is reasonably good, although the firststep height calls for a bit of a stretch; but well-placed grab handles are an asset. Standard fittings include heating and demisting equipment supplied from the engine aircooling system. And because the test vehicle had a sleeper cab a Webasto independent oil-fired heater unit was fitted. Other items in the cab included triple sun visors, two ashtrays and a plastics floor covering.

A comprehensive tool kit, which includes a full range of metric spanners. a 10-ton bottle jack and an inspection lamp (there is a socket for this on the dash) are supplied with the vehicle. The chassis as tested, but with the shortnon-sleeper cab, will probably be marketed in this country at about 15,200. The Duramin body as fitted to the test vehicle costs £335. Whilst this is a fairly high price for such a vehicle, the operator gets a lot of vehicle for his money, with many advantageous design features.