POUNDS PARED OFF A PASS ENGER CHASSIS

Page 66

Page 67

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

By L. J. Cotton, M.1.R.T.E. /N planning the Seddon passenger chassis the designer has taken extreme care to reduce the unladen weight to a minimum. It would be difficult to find any unit or component part of its construction which could be further lightened without reducing the efficiency of design.

The paring of pounds applies to the price of the vehicle as well as to

its weight, for at £1,250 it is one of the lowest-priced oil-engined passenger chassis on the market.

It must not be thought that the vehicle has been designed merely to impress prospective purchasers with its low price or weight. Lightness has been achieved by scientific planning. Well-tested proprietary units form the. basis of the chassis, but details of the assembly, such as brackets, have been constructed in the simplest and lightest manner. The cost of the vehicle is reduced by the efficiency of the Seddon organization, which carries the lowest possible overhead expenditure.

Like other vehicles of the Seddon range, the passenger chassis employs the Perkins P.6 Mark III N oil engine which, with a 31.-in. bore and 5-in, stroke, develops 70 b.h.p. at 2,200 r.p.m. It is equipped with a C.A.V pneumatically governed injection pump and two-spray injectors. Two lubricating-oil filters are provided, one in the sump and the other externally mounted on the pressure side of the system.

The Borg and Beck 12-in. single dry plate clutch, with spring dampers in the centre plate, has a total friction area of 151 sq. ins. A David Brown five-speed gearbox of new design is used, top, gear being direct drive. For ease of operation, the upper three ratios are in constant mesh and engaged by sliding-dog gears. Engine, clutch and gearbox are combined to form a unit which is retained in the chassis on three Metalastik rubber-to-metal-bonded mountings. '

Two propeller shafts, supported intermediately by a centre bearing with a spherical, self aligning seating, transmit power to the spiral bevel drive of the fully floating rear axle. Hardy Spicer universal couplings with needle-roller bearings are employed in the transmission line. To meet the arduous conditions encountered in bus operation, the finaldrive unit incorporates a straddle-mounted pinion and crown wheel with a four-pin differential.

The frame is of exceptional

interest. It is of maximum width from the gearbox to the rear crossmember and tapers at the fore end. In effect, the rear springs fall directly below the frame side members. These side-members are I in. thick and are tapered in depth, providing the greatest strength where needed, the maximum section being 8 ins. deep, with 21-in. flanges.

The first, second and third crossmembers are pressings, the first two supporting the engine. Tubular members are used for the three rear cross-members. An impression of the care taken in the detail work in frame design may be gathered from the central cross-member supporting the intermediate bearing of the propeller shaft. It is deep, to give maximum support, but is cut away almost to the flanges for lightness.

Girling two-leading-shop brake units on all four wheels are operated through a Lockheed hydraulic system with a Clayton Dewandre servo. The servo motor is driven in tandem with the fuel-injection

pump With a brake frictional area of 60.5 sq. ins, per ton, which was the calculation derived from one of our tests, attention to the brakes should be required only at wide intervals.

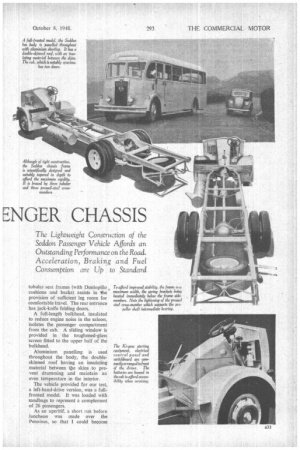

The body fitted to the chassis is a 32-seater and, with the exception of two seats over the wheel-arches, all others face forward. The use of tubular seat frames (with Dunlopillo cushions and backs) assists in the provision of sufficient leg room for comfortable travel. The rear entrance has jack-knife folding doors.

A full-length bulkhead, insulated to reduce engine noise in the saloon, isolates the passenger compartment from the cab. A sliding window is provided in the toughened-glass screen fitted to the upper half of the bulkhead.

Aluminium panelling is used throughout the body, the doubleskinned roof having an insulating material between tte skins to prevent drumming and maintain an even temperature in the interior.

The vehicle provided for our test, a left-hand-drive version, was a fullfronted model It was loaded with sandbags to represent a complement of 26 passengers.

As an aperitif, a short run before luncheon was made over the Pennines, so that I could become

better acquainted with the vehicle.

The stability and smooth riding of the Seddon over the granite-sett loads of Oldham caused me to scan the specification in search of shock absorbers, but I found that good springing was the sole answer to the excellent suspension.

I soon found that the test vehicle had lively acceleration and an ample capacity for tackling the steep gradients of the Pennines. For most of the distance we climbed in third gear, with occasional lapses into second gear for the sharper sections.

Full use was made of the brakes on the descent to the works and, although showing visible signs of heating, their efficiency appeared to be undisturbed. With light and wellbalanced steering, the Seddon rounded corners at a good speed with no apparent trace of body roll.

After luncheon the bus was put through its paces, and a hill of 1-in-6 gradient was the first objective. It was a short climb and was accom-: plished with ample reserve in second gear. A stop-start test was made without recourse to a lower ratio. Indeed, there was no reason to use bottom gear throughout the day's work.

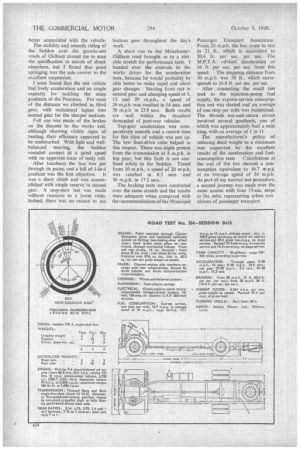

A short run to the ManchesterOldham road brought us to a able stretch stretch for performance tests. I handed over the controls to the works driver for the acceleration tests, because he would probably be able better to make rapid and silent gear changes Starting from rest in second gear and changing speed at 5, 13 and 29 m.p.h., a speed of 20 m.p.h. was reached in 14 secs. and 30 m.p.h. in 23.8 secs. Both results are well within the standard demanded of post-war vehicles.

Top-gear acceleration was comparatively smooth and a record time for this class of vehicle was put up. The low final-drive ratio helped in this respect. There was slight protest from the transmission at 8 m.p.h. in top gear, but this fault is not confined solely to the Seddon.. Timed from 10 m.p.h., a speed of 20 m.p.h. was reached in 8.5 secs. and 30 m.p.h. in 17.2 secs.

The braking tests were conducted over the same stretch and the results were adequate when compared with the recommendations of the Municipal Passenger Transport Association From 20 m.p.h. the bus came to rest in 21 ft., which is equivalent to 20.6 ft. per sec. per sec. The M.P.T.A. advised, deceleration of 16 ft. per sec. per sec. from this speed. The stopping distance from. 30 ntpli. was 58 ft., which corresponds to 16.8 ft. per sec. per sec.

After connecting the small test tank to the injection-pump fuel supply, the express-service consumption test was started and an average of one stop per mile was maintained. The 10-mile out-and-return circuit involved several gradients, one of which was approximately half a mile long, with an average of 1 in 11 The manufacturer's policy of reducing dead weight to a minimum was supported by the excellent results of the acceleration and fuel consumption tests Calculations at the end of the test showed a consumption equivalent to 16.7 m pg. at an average speed of 24 m.p.h As part of my normal test procedure. a second journey was made over the same course with four 15-see. stops to the mile, representing urban con. ditions of passenger transport.