Increased Steaming Range for Sentinel Wagons

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

Minor Modifications to Well-known Steam Wagons. A Foolproof Device for Tipping Bodies THE popular steam wagons made by the Sentinel Waggon Works, Ltd., Shrewsbury, will continue in their present forms. The range includes the doublegeared six-wheeler, a similar machine with a tipping gear, an overseas -pattern of the same type of chassis and double-geared four-wheelers, both for fixed and tipping bodies..

One of the most important alterations, in the eyes of the user, is the increase in the size of the water tank on the DG six-wheeler. The capacity is now 230 gallons—roughly a ton of water. This means that the wagon now has a steaming radius of about 50 miles, an increase of about 28 per cent.

Another new feature of importance is the safety device for the tipping gear. In a moment of aberration a driver might leave the control for the tipping gear in the 'tip" position and then start away with it. thus. When he next operates the pump a great strain is thrown upon the frame, the tipping gear and ancillary parts. To obviate this, a lever has been placed just in front of the driver's seat, the control rising automatically when the tipping gear isoperated. It remains upright, preventing the driver from assuming a normal driving position, until the tipping gear control has been restored to the " off " position.

Further to enhance the durability of these chassis,

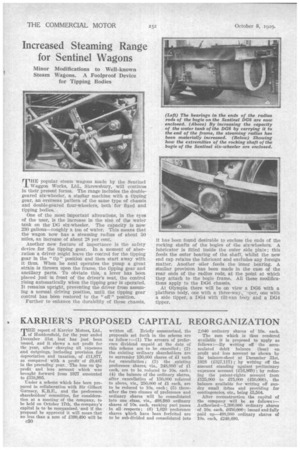

it has been found desirable to enclose the ends of the rocking shafts of the bogies of the six-wheelers. A lubricator is fitted inside the outer side plate; this feeds the outer bearing of the shaft, whilst the new end cap retains the lubricant and excludes any foreign matter. Another oiler feeds the inner bearing. A similar, provision has been made in the case of the rear ends of the radius rods, at the point at which they attach to the bogie frame. All these modifications apply to the DG6 chassis.

At Olympia there will be on view a DG6 with a platform body, one with a three-way,,–nper, one with a side tipper, a DG4 with tilt-van bOdy and a DG4 tipper.