A NEW

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

Four -wheeled

DRIVING UNIT

for Six-wheelers

T-IF, specialized manufacture of

individual chassis components is more developed in the United States than it is in this country and, although views may be divided, we do not remember hearing it denied that the leading concerns in America which are devoted to the construction of either engines, gearboxes or back axles, produce highly satisfactory components. As an example of specialized production we are able to publish this week a description of the Timken wormdrive four-wheel bogie, manufactured by the Timken-Detroit Axle Co., the sole European representative of which is the Automotive Products Co., of 3, Berners Street, London,

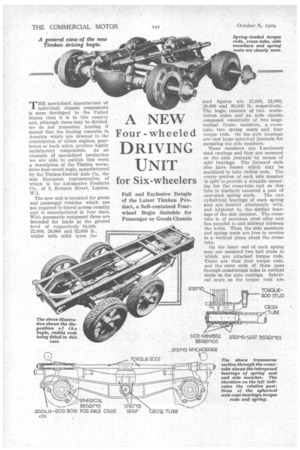

The new unit is intended for goods and passengy vehicles which are not required to travel across country and is manufactured in four sizes. With pneumatic equipment these are intended for loads at the ground level of respectively 16,000, 22,000, 28,000 and 32,000 lb,, whilst with solid tyres the load figures are 15,000, 21,000, 26,000 and 30,000 lb. respectively. The bogie consists of two wormdriven axles an an axle chassis composed essentially of two longitudinal frame members, a crosstube, two spring seats and four torque rods. On the axle housings are cast large spherical journals for mounting the side members.

These members are I-sectioned steel castings and they are mounted on the axle journals by means of split bearings. The forward ends also have bosses which may be machined to take radius rods. The centre portion of each side member is split to provide a straddle mounting for the cross-tube and on this .tube is similarly mounted a pair of cast-steel spring seats. The two cylindrical bearings of each spring seat are located alternately with, and adjacent to, the similar bearings of the side member. The crosstube is of seamless steel alloy and lies parallel to and midway between the axles. Thus, the side members and spring seats are free to revolve in a vertical plane about the crosstube, On the inner end of each spring seat are mounted two ball studs to which are attached torque rods. There are thus four torque rods, and the outer ends of them pass through countersunk holes in vertical studs on the axle castings. Spherical seats on the torque rods are pressed against both sides of the studs by heavy coil springs, these being protected by metal covers.

-Details of the Axles. _

The axles themselves are of the overhead-worm type, the axle shafts being fully floating. Two cross-pin universal joints are incorporated in the short shaft which conveys the drive to the rearmost axle. In the case of both axles, the worm pinion is carried at the forward end in a single Hyatt bearing, _ and at the rear end in two _inclined Timken roller bearings.

Thus, we have a self-contained unit which can be attached to any ordinary frame by orthodox semielliptic springs, the spring centres being bolted to the spring-seat castings in the usual manner. The use of radius rods from the chassis frame to the forward ends of the bogie side members is at the option of the chassis maker, With each model three widths of main frame attachment can be arranged.

Distinctive features of the unit are that it provides a drive on all four wheels apd a balanced suspen

sion with equal distribution of weight. The driving torque is divided equally between the two axles, and the torque of the axles in braking and acceleration is transmitted to torque rods, being cushioned by the torque-rod springs and the main springs. The axle torque ' caused by changes in angular velocity: of the wheels when travelling over rough ground is similarly cushioned. The axles remain parallel regardless of load distribution in the vehicle.

The cross-tube being mounted in dual cylindrical bearings in each of the side members, any weaving of the unit is prevented. Another point in favour of the bogie is that it may be used under chassis frames which have been designed for fourwheelers and it can be adapted for either Hotchkiss or radius-rod torque resistance. The bogie will take any ordinary tyre equipment, dual pneumatics of high or low pressure or solid tyres being equally suitable.

Optional Braking Equipment.

As regards braking, the unit is supplied with either hydraulic or air-operated brakes and it is par_ ticularly suited for them since the braking is not affected by any position which the axles may take. Another point worth mentioning is that the axles themselves are similar to thousands of Timken worm-drive axles that are in use throughout the world,.

To Be Shown at Olympia.

The Automotive Products Co. will be showing this unit at the commercial-motor Show at Olympia in November and on the same. stand will be seen the well-known Borg and Beck clutch, not to mention two other Timken products, namely, a front axle equipped for hydraulic braking' and a spiral-bevel-driven rear axle of the fully floating type intended for overslung springs. The well-known Hannuin steering gear will also be shown.

The components marketed by the Automotive Products Co. have. always held a high reputation in this country and there is no doubt that the Timken four-wheel-driving unit will rouse considerable interest.