Celect cycle

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

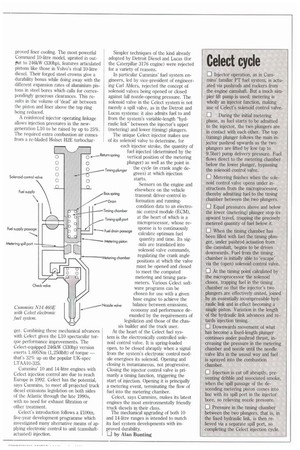

El Injector operation, as in Cummins' familiar PT fuel system, is actuated via pushrods and rockers from the engine camshaft. But a much simpler lift pump is used; metering is wholly an injector function, making use of Celect's solenoid control valve.

0 During the initial metering phase, as fuel starts to be admitted to the injector, the two plungers are in contact with each other. The top (timing) plunger follows the main injector pushrod upwards as the two plungers are lifted by low (up to 9.5bar) pump delivery pressure. Fuel flows direct to the metering chamber below the lower plunger, bypassing the solenoid control valve.

12 Metering finishes when the solenoid control valve opens under instructions from the microprocessor, thereby admitting fuel to the timing chamber between the two plungers.

El Equal pressures above and below the lower (metering) plunger stop its upward travel, trapping the precisely metered quantity of fuel below it.

El When the timing chamber has been filled with fuel the timing plunger, under pushrod actuation from the camshaft, begins to be driven downwards. Fuel from the timing chamber is initially able to 'escape' via the (open) solenoid control valve.

El At the timing point calculated by the microprocessor the solenoid closes, trapping fuel in the timing chamber so that the injector's two plungers are effectively united, joined by an essentially incompressible hydraulic link and in effect becoming a single piston. Variation in the length of the hydraulic link advances and retards injection timing.

El Downwards movement of what has become a fixed-length plunger continues under pushrod thrust, increasing the pressure in the metering chamber and nozzle until the needle valve lifts in the ususal way and fuel is sprayed into the combustion chamber.

0 Injection is cut off abruptly, preventing dribble and associated smoke, when the spill passage of the descending metering piston comes into line with its spill port in the injector bore, so relieving nozzle pressure.

Ll Pressure in the timing chamber between the two plungers, that is, in the fixed hydraulic link, is then relieved via a separate spill port, so completing the Celect injection cycle.