INSTANT

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

RESPONSE

Cummins has revamped its well-liked 10 and 14-litre diesel engines to respond to legislative requirements, tough competition and changing operational requirements. The ace up its sleeve is Celect — a state-of-the-art fuel system.

• Celect, Cummins' electronically controlled fuel injection system, made its European debut at the NEC show; it will not become available on this side of the Atlantic before mid-1992. Initial applications have yet to be decided, but the popularity of the LIO in urban bus applications, where exhaust emissions could become subject to more stringent legislation, would certainly make it a prime candidate for the European Celect programme.

Electronic injection control also enhances performance and economy of course, which would make Celect desirable on Cummins' biggest 14-litre truck diesels. Its US launch earlier this year coincided with a radical re-design of the 14-litre lump. Code-named N14, the modified engine retains the 140x152mm bore and stroke of the familiar NTE (called the Super E in the UK), but not much else.

Surprisingly, the N14, with its new cylinder block and head design, is somewhat heavier than the NTE. Weight has been removed from understressed areas, but that is more than outweighed by beefing up those parts of the engine which are close to their limits in the charge-cooled 347kW (465hp) NTE, when judged against Cummins' durability target of 800,000km.

GREATER COOLING

Key changes include a 25% increase in crankpin diameter, with a strengthened conrod to suit. The new, stronger cylinder block allows better coolant circulation around the liners; the aluminium pistons are anodised in the combustion-bowl area to resist cracking and heat corrosion. Oil flow below the piston crown is increased for greater cooling and durability.

In all N14 variants, even those without Celect, Cummins' PT mechanical injector operating linkage (cam follower, pushrods and pivot points) has been strengthened to withstand the higher loads imposed when injection pressures are raised in the future by up to 10% to an anticipated 1,360 bar or more.

Uprated auxiliaries include a higheroutput Holset HT3B turbocharger, a bigger oil pump and a more efficient oil cooler. Air-to-air charge-cooling, which is more of a novelty in the US than it is in Europe, is now standard on the most powerful N I4s.

One reason why the new generation 14litre engine needed to be beefier, and thus heavier, than its predecessor is its impressive torque spread: torque is related directly to cylinder pressure, which in turn determines the strength required of almost every engine component.

Thanks to Celect electronic injection, which is now fitted as standard on all N14s with an output of more than 306kW (410hp), it is possible to tailor the power, and especially the torque curve, to an unprecedented degree.

Maximum power is delivered at only 1,700rpm — the engine will run up to a governed 2,100rpm — and the torque exerted by the top-rated 343kW (460hp) N14 released in the US reaches a massive 2,100Nm (1,549Ibft); equalling that of Renault's big Mack vee-eight and bettered in Europe only by MAN's vee-10.

During the N14 development programme Cummins was also aware that its lead in the big diesel durability stakes was being steadily eroded by its competitors' advances. In Europe, big-selling, established engines like Volvo and MAN 12litre units, Scania's 11 and 14-litre models, and Mercedes' ubiquitous 14.6-litre veeeights have had their life expectancies steadily improved, from a typical 400,000km a decade ago to 700,0001un.

At a nominal 800,000km, the durability of Cummins' NTE truck engines was implicitly under challenge. With the N14, the

company is seeking not only to maintain NTE endurance levels in the face of much higher torque loadings, but to reduce wear rates and postpone the likelihood of component failure. No figure is being put on N14 durability claims, but at least a million kilometres (620,000 miles) will be expected by many customers, particularly in today's economic climate where operators' instincts are to extend vehicle replacement cycles.

The name Command has been coined by Cummins to describe all engines on which Celect can now be specified as an option in the US: so far that means the N14 and a less drastically updated LIO engine. In addition to the noise-reducing front timing cover and bigger sump already introduced over here, that updating includes revised block, again with im proved liner cooling. The most powerful Command 10-litre model, uprated in output to 246kW (330hp), features articulated pistons like those in Volvo's rival 10-litre diesel, Their forged steel crowns give a durability bonus while doing away with the different expansion rates of aluminium pistons in steel bores which calls for correspondingly generous clearances. This results in the volume of 'dead' air between the piston and liner above the top ring being reduced.

A reinforced injector operating linkage allows injection pressures in the newgeneration L10 to be raised by up to 25%. The required extra combustion air comes from a re-bladed Ho!set H2E turbochar ger. Combining these mechanical advances with Celect gives the L10 spectacular torque performance improvements. The Celect-equipped 246kW (330hp) version exerts 1,695Nm (1,250Ibft) of torque — that's 32% up on the popular UK-spec LTAA10-325.

Cwnrnins' 10 and 14-litre engines with Celect injection control are due to reach Europe in 1992. Celect has the potential, says Cummins, to meet all projected truck diesel emissions legislation on both sides of the Atlantic through the late 1990s, with no need for exhaust filtration or other treatment.

Celect's introduction follows a £100m, five-year development programme which investigated many alternative means of applying electronic control to unit (camshaftactuated) injection. Simpler techniques of the kind already adopted by Detroit Diesel and Lucas (for the Caterpillar 3176 engine) were rejected for a variety of reasons.

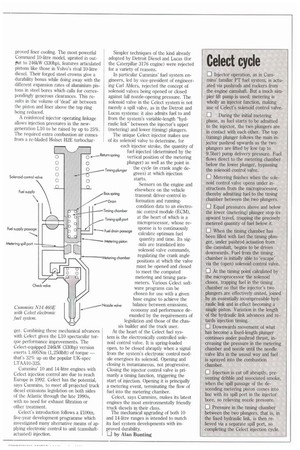

In particular Cummins' fuel system engineers, led by vice-president of engineering Carl Alders, rejected the concept of solenoid valves being opened or closed against full nozzle-opening pressure. The solenoid valve in the Celect system is not merely a spill valve, as in the Detroit and Lucas systems: it also admits fuel to and from the system's variable-length "hydraulic link" between the injector's upper (metering) and lower (timing) plungers.

The unique Celect injector makes use of its solenoid valve to determine, for each injector stroke, the quantity of fuel injected (determined by the vertical position of the metering plunger) as well as the point in

Timing the cycle (in crank angle degrees) at which injection starts.

Sensors on the engine and elsewhere on the vehicle

Bias spring transmit driver-control information and running

Drain

condition data to an electro

Timing chamber nic control module (ECM), at the heart of which is a Timing spill port microprocessor, whose re

sponse is to continuously calculate optimum fuel quantity and time. Its signals are translated into solenoid valve commands,

Meterin chamber regulating the crank angle g positions at which the valve must be opened and closed to meet the computed metering and timing parameters. Various Celect software programs can be chosen for use with a given base engine to achieve the balance between emissions,

Nozzle valve

economy and performance de manded by the requirements of legislation and those of the chas sis builder and the truck user.

At the heart of the Celect fuel system is the electronically controlled solenoid control valve. It is spring-loaded open, to be closed abruptly when a signal from the system's electronic control module energises its solenoid. Opening and closing is instantaneous, not progressive. Closing the injector control valve is primarily a timing function, triggering the start of injection. Opening it is principally a metering event, terminating the flow of fuel into the metering chamber.

Celect, says Cummins, makes its latest engines the most environmentally friendly truck diesels in their class.

The mechanical upgrading of both 10 and 14-litre ranges is intended to match its fuel system developments with imaroved durability. LJ by Alan Bunting