Mobility speeds lubricatiot

Page 82

Page 83

If you've noticed an error in this article please click here to report it so we can fix it.

by lain Sherriff

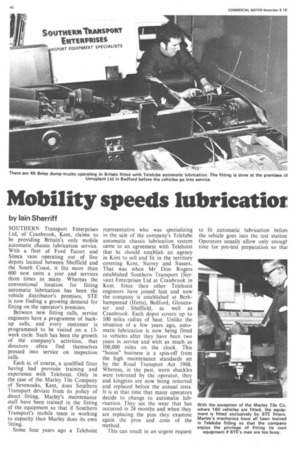

SOUTHERN Transport Enterprises Ltd, of Cranbrook, Kent, claims to be providing Britain's only mobile automatic chassis lubrication service. With a fleet of Ford Escort and Simca vans operating out of five depots located between Sheffield and the South Coast, it fits more than 600 new units a year and services three times as many. Whereas the conventional location for fitting automatic lubrication has been the vehicle distributor's premises, STE is now finding a growing demand for fitting on the operator's premises.

Between new fitting calls, service engineers have a programme of backup calls, and every customer is programmed to be visited on a 13week cycle. Such has been the growth of the company's activities, that directors often find themselves pressed into service on inspection calls.

Each is, of course, a qualified fitter having had previoUs training and experience with Telehoist. Only in the case of the Marley Tile Company of Sevenoaks, Kent, does Southern Transport deviate from its policy of direct fitting. Marley's maintenance staff have been trained in the fitting of the equipment so that if Southern Transport's mobile team is working to capacity then Marley does its own fitting.

Some four years ago a Telehoist representative who was specializing in the sale of the company's Telelube automatic chassis lubrication system came to an agreement with Telehoist that he should establish an agency in Kent to sell and fit in the territory covering Kent, Surrey and Sussex. That was when Mr Don Rogers established Southern Transport (Service) Enterprises Ltd at Cranbrook in Kent. Since then other Telehoist engineers have joined him and now the company is established at Berkhampstead (Herts), Bedford, Gloucester and Sheffield, as well as Cranbrook. Each depot covers up to 100 miles radius of base. Unlike the situation of a few years ago, automatic lubrication is now being fitted to vehicles after they have been two years in service and with as much as 100,000 miles on the clock. This "bonus" business is a spin-off from the high maintenance standards set by the Road Transport Act 1968. Whereas, in the past, worn shackles were tolerated by the operator, they and kingpins are now being removed and replaced before the annual tests. It is at that time that many operators decide to change to automatic lubrication. They see the wear that has occurred in 24 months and when they are replacing the pins they examine again the pros and cons of the method.

This can result in an urgent request to fit automatic lubrication befor( the vehicle goes into the test station Operators usually allow only enougltime for pre-test preparation so thai any additional work like fitting automatic lubrication has to be done in double-quick time.

Thirty per cent of the new equipment is fitted at the operator's premises, the remainder at the distributor's premises wherever that might be. An advantage of Southern's mobility is that operators in South Yorkshire may for some very good reason purchase vehicles in Bedfordshire and although the arrangements for automatic lubrication may be concluded through the Sheffield office, the fitting would be carried out by the Bedford office. To avoid confusion through double booking, all fitting requests are channelled to the company's head office at Cranbrook from where fitting instructions are issued. On completion of job, the job card is returned to Cranbrook and filed for reference and programming into the follow-up calls.

According to Mr Rogers, the equipment should last the lifetime of the vehicle, but he acknowledges that often working conditions and neglect reduce the life span. This is why the mobile teams carry a complete range of replacement parts. Vehicle inspections can be carried out either on the customer's premises or when the vehicle is at work. A check of the system, according to Mr Rogers, takes "only a few minutes". Fitters can, if necessary, carry out inspections while the vehicle is being loaded.

In the forefront of every operator's mind, of course, is the question of costs. Mr Rogers gave me the capital costs covering a wide range of vehicles. They range from E38 for a BLMC JU250 up to £255 for a Guy Big .1 eight-wheeler. The fitting time varies depending on the size of the vehicle but generally falls within a three to five-hour span. There are two basic systems in the Teletube range; one based on the number of times the engine stops and starts in a day, the other based on the more accurate method of pre-set dispensing.

The first method is suitable for vehicles engaged in stop-start work provided they are doing around 12 stops in a day, but Mr Rogers impresses that this means 12 engine stops. This system employs a halfpint reservoir and on a 12-stop day it lubricates four points with each engine start and utilizes 0.144 cubic inches of oil in a day. This is equivalent to s3a th of a pint per day. Just as less than 12 stops can prove inefficient because of lack of lubrication the danger is that over lubrication can also occur, as happened with a fleet of milk delivery vehicles, each one of which was stopping 150 times. There is also on record one instance of Southern Transport turning down a sale because the vehicles were not moving long distances or at any speed, because equipment would not then have been brought into action.

The method most favoured by operators and by Southern Transport is the one which uses the LS304 heavy-duty equipment where the reservoir has a one gallon capacity and the system is pre-set to discharge to meet the operational requirements of the vehicle. Discharge can be set for intervals of anything from five minutes to one hour 40 minutes, but, generally speaking, it is set at 20minute cycles giving three lubrication phases in an hour.

A Volvo F86 tractive unit with 20 points costs £166 to supply and fit.

Written down over a five-year period, this will produce a capital cost of 66p per week. The system uses 3.51 cubic inches of oil per day and estimating the cost of oil at El per gallon, the lubricant costs 61) per week a total operating cost of 72p per week. There are 277.42 cubic inches of lubricating oil to the gallon.

A Foden eight-wheeler with 59 points costs £250 to supply and fit, and uses 8.019 cubic inches per day. Using the same depreciation time and oil costs, the operating cost per week is E1.13.

A Ford DA2114 with 24 points costs 97p fitted and uses 1.944 cubic inches of oil daily. This gives a total operating cost of 41p per week.