7-ton Load 8.35 m.p.g.

Page 133

Page 134

Page 139

Page 140

If you've noticed an error in this article please click here to report it so we can fix it.

Albion Caledonian Eight-wheeler has Low Chassis Weight to Allow 17-ton Payloads with Light-weight Bodies

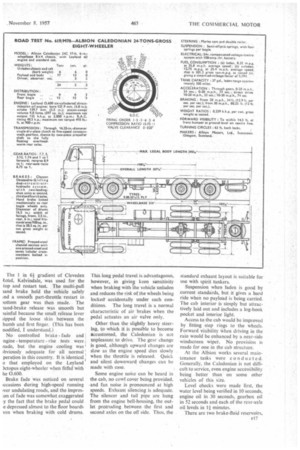

By John F. Moon, A.M.I.R.T.E. MUCH weight has been saved in the new Albion Caledonian eight-wheeled goods chassis, which was announced in The Commercial Motor last week, with the result that the kerb weight of chassis and cab alone is only 6 tons 6 cwt. This makes it possible to carry a payload of well over 17 tons when a light-alloy platform or drop-sided body is fitted.

Thus, in terms of payload-ton-m.p.g. the Caledonian is one of the most economical of British heavy goods vehicles. When tested over an undulating 20-mile route to the north of Glasgow, an average laden consumption rate of 8.35 m.p.g. was returned, the average speed being 25.8 m.p.h.

Although Leyland engine, gearbox and cab are used, the rest of the Caledonian chassis is of Albion design and manufacture. The frame, which is of h-in. material, has a maximum depth of 10i in. and is strongly braced by tubular and pressed-steel crossmem ber s. Split-pinned nuts are employed at vital parts, so there is little fear of frame failures occurring despite the light weight.

The axles are inherited from the HD range of heavy vehicles, which went out of production over four years ago, and the suspension is the same, four springs and balance beams being employed at the rear bogie. Another feature of the Caledonian which was to be found on the HID models is that the second, and not the leading, axle of the front bogie is braked.

A departure from the HD range is the use of air-hydraulic brakes, a dualcircuit layout having been designed. This incorporates one large air-pressure actuator and master cylinder, which operates the brakes on the second and third axles, and a smaller unit to take effect on the fourth axle. A single reservoir, air compressor and brake valve are employed. Should one of the hydraulic pipes in either circuit leak, a certain amount of braking action will still be available.

The Leyland 0.600 125-b.h.p. oil engine is unit-mounted with the fivespeed direct-top gearbox, and instead of the swinging-link mountings normally employed with this unit, two rubber pads in compression and shear support the front of the engine, whilst at the bell housing there are two rubber bushes in shear. This mounting layout proved to be extremely effective during the test and at all engine speeds no vibration was transmitted to the cab or frame-mounted controls.

Because of the comparatively low axle ratio of 6.75 to 1, the governed speed of the engine has been raised to 2000. r.p.m., which gives a top speed of 36 m.p.h. and improves the acceleration characteristics without detracting from the vehicle's maximum gradient ability. Standard tyres are 36 by 8-in. (12ply), but 9.00 by 20-in. (12-ply) tyres may be fitted as alternative equipment. Other additions to the standard specification include a third differential, power steering, and cab heating and demisting gear, none of which was fitted to the test vehicle.

As supplied for test, the Caledonian was carrying an imposed load of 17 tons 13 cwt., and together with myself and Albion driver in the cab, the vehicle was tested at a gross weight of 24 tons 2+ cwt. The front tyres were carrying a slightly greater load than the rear tyres.

From the Albion works, I drove the chassis to Buchlyvie, the read chosen being narrow and hilly once outside the Glasgow area. It soon became apparent that to obtain the best performance the engine speed had to be kept high and this entailed prolonged use of the indirect ratios on all but level stretches, although at no time did it become necessary to drop down as low as second gear.

Another feature that created an instant impression was the heaviness of the steering, particularly at very low speeds. On the open road it seldom became necessary to slacken speed to negotiate sharp corners once I had became accustomed to the steering characteristics, but the vehicle would be much less tiring to handle on long journeys if the optional power steering were to be fitted.

At Buchlyvie, the fuel test tank was topped up to overflowing and a 10-mile fuel-consumption test in the direction of Stirling was conducted. The first half of this route is severely undulating, whilst the second half is almost completely level.

The 10 miles were covered at an average speed of 26.8 m.p.h., the consumption rate being 9.6 m.p.g.

Before making the return run, braking and acceleration tests were carried out on the "Stirling Straight." A pause in the heavy rain which fell throughout most of the day and a strong drying wind provided a useful stretch of dry, level road.

Three-axle Braking Although not outstanding the braking figures are reasonable for a vehicle of this weight braking on only three axles and the delay in the system was only slight. Much better braking figures would, of course, have resulted had all four axles carried brakes. I think that all eight-wheelers should have eight-wheel brakes, even though it would, in the case of the Albion, raise the unladen weight slightly.

Again, reasonably satisfactory acceleration figures were achieved, particularly in view of the low power-toweight ratio. The engine pulled well in the direct drive between 10 m.p.h. and 20 m.p.h. and the transmission was smooth when drawing away in this gear from 8 m.p.h. The time to accelerate from 20-30 m.p.h. in direct drive was 10 seconds longer than that taken from 10-20 m.p.h., because of the fall-off in torque above 900 r.p.m.

The return run to Buchlyvie was made in heavy rain, which combined with the stiffer gradients in this direction to cause a heavier fuel consump. tion rate and a slower average. The overall average figures for the out-andreturn journeys, however, are excellent particularly considering the amount of gear work involved over half the distance.

Under normal trunk ing conditions in England, where road gradients are less severe, laden consumption rates of at least 8.5 m.p.g. should be achieved and this with a payload of 161-17 tons

Unladen Consumption Run

On the second day of the test, the Buchlyvie-Stirling-Buchlyvie run was made again with the vehicle unlader except for one ton weight which was left on to represent a heavy drop-sided body, the total running weight being approximately 7-+ tons.

On this run it was possible to keer in top gear for almost the whole time in each direction and an average fuel. consumption rate of 12.75 m.p.g resulted. The average speed was deliberately kept down so that it was almost the same as that returned during the laden run. An operator running laden in only one direction could expec an overall average consumption figure of 10.5-11 m.p.g. in normal service. The 1 in 61 gradient of CIeveden Zoad, Kelvindale, was used for the top and restart test. The multi-pull land brake held the vehicle safely ind a smooth part-throttle restart in iottom gear was then made. The land-brake release was smooth but minful because the small release lever lipped the loose skin between the humb and first finger. (This has been nodified, I understand.) No controlled brake fade and I ngine temperature rise tests were

nade, but the engine cooling was ' bviously adequate for all normal ; peration in this country. It is identical i o that employed on the Leyland )ctopus eight-wheeler when Mkt with he 0.600.

Brake fade was noticed on several ecasions during high-speed running over undulating roads, and the impresLon of fade was somewhat exaggerated ,y the fact that the brake pedal could e depressed almost to the floor boards ven when braking with cold drums.

This long pedal travel is advantageous, however, in giving keen sensitivity when braking with the vehicle unladen and reduces the risk of the wheels being locked accidentally under such conditions. The long travel is a normal characteristic of air brakes when the pedal actuates an air valve only.

Other than the slightly heavy steering, to which it is possible to become accustomed, the Caledonian is not unpleasant to drive. The gear change is good, although upward changes are slow as the engine speed dies slowly when the throttle is released. Quick and silent downward changes can be made with case.

Some engine noise can be heard in the cab, no cowl cover being provided, and fan noise is pronounced at high speeds. Exhaust silencing is adequate. The silencer and tail pipe are hung from the engine bell-housing, the outlet protruding between the first and second axles on the off side. Thus, the standard exhaust layout is suitable for use with spirit tankers.

Suspension when laden is good by current standards, but it gives a hard ride when no payload is being carried. The cab interior is simply but attractively laid out and includes a log-book pocket and interior light.

Access to the cab would be improved by fitting step rings to the wheels. Forward visibility cvhen driving in the rain would be enhanced by a near-side windscreen wiper. No provision is made for one in the cab structure.

At the Albion works several maintenance tasks were conducted. Generally, the Caledonian is not difficult to service, even engine accessibility being better than on some other vehicles of this size.

Level checks were made first, the water level being verified in 10 seconds, engine oil in 30 seconds, gearbox oil in 52 seconds and each of the rear-axle oil levels in 11 minutes.

There are two brake-fluid reservoirs, mounted side by side behind the cab on the off side, and to check the levels in both took only 13 seconds: The four 6-v. batteries are carried in a crate on the near side of the frame, two selflocking nuts securing the cover. Stooping, as would be the case were a body to be fitted, I checked the electrolyte levels in the cells in just under 2 minutes. • There are three filters in the fuel system. The.primary filter has a gauze element and is mounted on the inside of the chassis frame adjacent to the fuel, tank. Working from below I removed and replaced the element in 1 min. 50 sec. I learned that it is wise to slacken off the main feed union at the fuel tank when doing this job with a full tank. If the filter bowl is removed without slackening this union, all the contents of the tank are drained out, because the filter is at a lower level than the tank.

The secondary fuel filter has a cloth element and it is located inside the near-side frame member. The filter clemebt takes min. to remove and replace. The final fuel tiller, which also has a cloth element, is mounted on the near-side of the engine, • high up for easy access, and its element can be taken out and replaced in 2 min. 40 sec., this time including raising and lowering the bonnet.

Having stripped these three filters it was necessary to bleed the system. This took longer than it should have done (5 min.), because of the ridiculously small priming lever on the lift pump and the difficulty of slackening the bleed valve on the top of the injection pump.

No Centrifugal Filter

I did not attempt to strip the oil filter, as this is not particularly easy to reach, and in any case, the bowl is secured by seven bolts, Contrary to normal Albion practice, a centrifugal oil filter is not fitted.

Brake adjustment is simple, each of the six brakes having a single squareheaded adjuster of the normal Girling pattern. The brakes on each axle can be adjusted in 2i min., including jacking up both wheels simultaneously and lowering them.

The spare wneel, which is carried at the rear of the frame, is secured by a -crossbar which carries two sets of locknuts underneath the carrier. This involves a rather lengthy procedure which I did not attempt, and it would entail using two spanners to slacken off each lock-nut.

Fuses, which are of the replaceablewire type, are housed in the control panel and situated to the right of the driving seat.

A complete toolkit, including special tools for work on the engine, is supplied and all normal maintenance jobs can be carried out without having to use workshop equipment.

The Caledonian has been designed as a light-weight and relatively inexpensive maximum-load eight-wheeler for solo use over all normal trunk routes in Britain. Although perhaps not as fully equipped as certain other eightwheelers at present in production, the price advantage is important, and .nothing essential has been omitted from the chassis, neither has weight saving been achieved at the expense of strength.