A Bus Converted to Oil Gives Remarkable Results

Page 195

If you've noticed an error in this article please click here to report it so we can fix it.

By W. H. Goddard, A.M.I.Mech.E., M.I.P.T.

ALTHOUGH a very large number of vehicles, both lorries and buses, has been converted to oilers, very little has been published concerning their performance, or the results achieved.

On May 23, 1933, a Leyland Titan double-deck bus, which had just been converted to oil power, utilizing a Gardner 6LW 102 unit, was put into service by the corporation transport department of one of our largest northern cities. The total mileage run from that date up to October 1., 1935 (about two years and tour months), was 145,171, which is an average of about 190.7 miles per day. The routes over which this bus has been running are mostly hilly, some of ' the grades being very stiff. In spite of this the average rate of oil-fuel consumption over the whole period was 9.83 m.p.g.; and the average figure for lubricating oil, 680 m.p.g., winch can be considered as a remarkable performance. On the few more or less level routes the fuel consumption was 11 m.p.g. or more.

Arduous Service.

This bus was on a service involving an average of eight stops per mile, so that during the whole period the engine has had to stop and start no fewer than 1,161,368 times, which is a severe test for both engine and transmission. In the rush hours, fully loaded up to its legal limit of 10 tons, starting up on a heavy grade eight times per mile is hard on any engine.

The fortnightly routine work of adjusting tappets, cleaning fuel and oil filters, attending to sprayers, etc., cost,

all told, the small sum of is. 9d.i.e., about 10d. per fortnight—an insignificant sum when compared to the average for a petrol-engined bus.

When we come to the important matter of general maintenance and the replacement of parts the results are even more remarkable. The original big-end bearings and main crankshaft bearings ran perfectly over the whole period without adjustment, and except for a little ," flaking of the metal in two or three bearings, due to a cracked oil pipe, could actually have been put back for a further run, even after this distance of 145,000 miles.

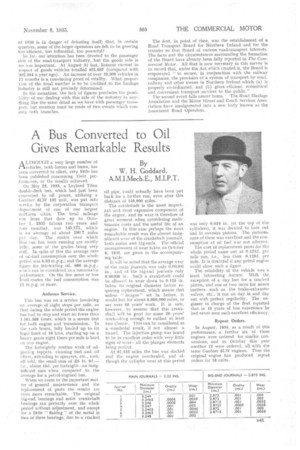

The crankshaft is the most important and most expensive component of the engine, and its wear is therefore of great moment when considering maintenance costs and the useful life of an engine. In this case perhaps the most remarkable result was the almost insignificant wear of the crankshaft journals, both mains and big-ends, The official measurements of wear taken on October 8, 1935, are given in the accompanyjug table.

It will he noted that the average wear of the main journals was only 0.00306 in., and of the big-end journals only 0.00308 in. SuCh a crankshaft could be allowed to wear down to 0.125 in. below its original diameter before requiring replacement, which means that unless " fatigue" set in before, it would last for about 5,000,000 miles, or say over 50 years' work. It is safe, however, to assume that this crankshaft will be good for some 20 years' work—long enough to outlast at least two chassis. This can be considered as a wonderful result, if not almost a record. The injection pump was found to he in excellent order with very little signs of wear—all the plunger elements being perfect.

At 81,555 miles the bus was docked and the engine overhauled, and although the cylinder wear at this period was only 0.019 in. (at the top of the cylinders), it was decided to bore out and fit oversize pistons. The performance of these was excellent and the consumption of oil fuel was not affected.

The cost of replacement parts for the whole period came out at 0.121d. per mile run, i.e., less than 0.125d. per mile. It is doubtful if any petrol engine could show such a figure.

The reliability of the vehicle was a most interesting feature. With the exception of a day lost for a cracked piston, and one or two more for minor matters—such as the brake-exhauster valves, etc., it ran on day in and day out with perfect regularity. The engineer in charge of the fleet reported that in 15 years of bus experience he had never seen such excellent efficiency.

Repeat Orders. .

In August, 1934, as a result of this performance, a further six of these engines were ordered for similar conversions, and in October this year another 12 were ordered, all with the same Gardner 6LW engines, Thus the original engine has produced repeat orders for 18 units.