THE STRAKER-CLOUGH TROLLEY-BUS.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

First Description of the Latest Production of a Rubber-tyred Vehicle to Compete with the Tramcar on Its Own Territory.

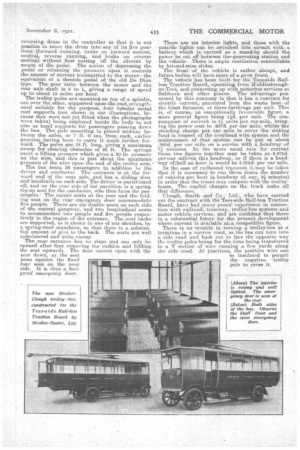

IN the issue of The Commercial Motor for October 11th there appeared a brief illustrated description of the first' Straker-Clough trolley-bus—the first and only :reference that has been made in the Press to a production which we consider of outstanding interest to the motor industr"... We feel strongly that this new development in passenger road vehicle design should be appropriated by the motor trade, and we are glad to be privileged to as

saciate the name of that pioneer in heavy vehicle work, Mr. Sidney Straker., of Straker-Squire, Ltd., with Mr. Norman Clough, of Clough, Smith and Co., Ltd., in the design and production of a notable vehicle.

We had the pleasure of inspecting the StrakerClough bus as it was-approaching completion at the Straker-Squire works, and it fully came up to our expectations.. 'The design is good throughout, the ehas,sis being simple, the installation of the electrical equipment excellent, the controls well thought out, 4nd the body eminently practical.

The standard five ton Straker-Squire chassis has been taken because it was .concluded

• by Mr. Clough that, with its springing, steering position and other features, it would be entirely suitable for the work with the minimum of Adaptation. The only alteration that w.a,s made was in the matter of the rake of the steering column. The angle is less (as can be seen in the illustration in our article of October 11th), but, for the speeds at which the vehicle will be required to travel in public service, it is at quite a Comfortable rake. The chasms, from the front universal joint of the ,propeller shaft rearwards, is unaltered. Coupled to the front universal joint is an electric motor of the latest railway ventilating type, which is a great advance upon the enclosed motor. It is controlled through a pedal with which is interlocked the lever which operates the reversing drum in the controller so that it is not possible to move the drum into any -of its five positions (forward running, brake on forward motion, neutral, reverse running, and brake on reverse motion) without first cutting off the carrent by means of the pedal. The action of depresiing the pedal or releasing the pressure upon it controls the amount of current transmitted to the motor—the equivalent of a throttle pedal of the old De Dion type. The gear ratio between the motor and the rear axle shaft is 8 to 1, giving a range of speed up to about 15 miles per hour. The trolley poles are mounted on top of a spindle, one over the other, supported upon the roof, strengthened suitably for the purpose, four tubular metal roof supports (not shown in our illustrations, because they were not yet fitted when the photographs were taken) being employed inside the body to act also as hand supports for passengerspassing down the bus. The pole mounting is placed midway between the axles, or 7 ft. 6 ins. fiorn each, earlier practice having been to carry it much farther forward. The poles are 18 ft. long, giving a maximum, sweep for clearing obstacles of 26 ft. The springs exert a lifting pressure which gives a 30 lb. pressure on the wire, and this is just about the maximum pressure of the wire upon the end of the trolley arm. The bus seats 36 passengers in addition to the driver and conductor. The entrance is at the forward end of the near side, and has asliding door and handrails on each side. The -driver is partitioned off, and on the rear side of the partition is a spring tip-up seat for the conductor, who thus faces the passengers.' The corner seats at the rear and the folding seat on the rear emergency door accommodate five people. There are six double seats on each side of the -central gangway, and two longitudinal seats to accommodate two people and five people tespectively in the region of the entrance. The seat backs are supported, as is shown in one of our sketches, by a spring-steel stanchion, so that there is a substantial amount of give to the back. The seats ate well upholstered and quite roomy.

The rear entrance has no steps and can only be opened after first removing the cushion and folding the seat upwards. The door cannot open with the scat down, as the seat jams against the fixed rear seat on the near side. It is thus a foolproof emergency door. There are six interior lights and these with the outside lights can be switched into circuit with. a battery which is carried as a stand-by should the power be cut off between thee generating station and the vehicle. There is ample ventilation controllable by hit-and-miss slides. The front -of the vehicle is rather abrupt, anel future bodies will have more of a prow front.

The vehicle has been built for the Tees-side Railless Traction Board, operating from Middlesbroughon-Tees, and connecting up with motorbus services at Saltburn: and other places. The advantage possessed by this company is that it hae a contract for electric current,. generated from the waste heat. of the blast furnaces, at three-farthings per -unit. This is, of course,an exceptionally favourable, figure, a more general figure being lid. per unit. 'The con.siunption of current is 1 units per car-mile, bringing the power cost to .937d. per car mile, whilst-the standing charge per car mile to cover the sinking fund in respect of the overhead wire system and the maintenance of that system can be put at about .860d. per car mile on a service with a_headway. of 71 minutes. At the more usual rate for current these two figures together may be taken at-2.875d. per3car mile-ion this headway, or if there is a headway oflhalf an hour it would be 5.315d. per car mile.

In the ease of railbound tramcars it:uia.y be taken that it is necessary to run three times the number of vehicles per hour (a headway of, say, minutes) in order that,the trams may compete with the trolleybuses. The caprtal charges on the track make all that difference.

Clough, Smith and Co., Ltd:, who have carried out the contract with the Tees-side Rail-less Traction Board, have had many years' experience in connection with railroad; tramway, trolley-bus systems and motor vehicle services, and are confident that there is a substantial future for the present development where current is available at.a competitive figure. There is no trouble in turning a trolley-bus at a terminus in a narrow road, as the bus can turn into a side road and back out to face the "opposite way the trolley poles being for the time being transferred to a V section of wire running a few yards along the side road. At junctions, the positive wire can be insulated to permit the• negative trolley pole to cross it.