Superheated Steam : Article No. IV.

Page 21

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

By David J. Smith.

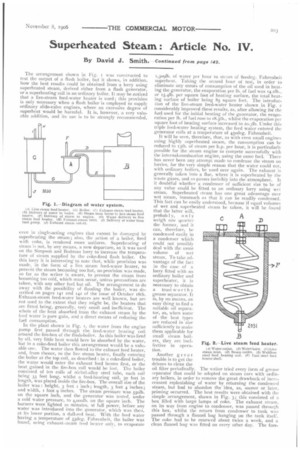

The arrangement shown in Fig. I was constructed to test the output of a flash boiler, but it shows, in addition. how the best results could be obtained front a lorry using superheated steam, derived either from a flash generator, Or a superheating coil in an ordinary boiler. It may be noticed that a live-steam feed-water heater is used; this provision is only necessary when a flash boiler is employed to supply ordinary slide-valve engines, where an excessive degree of superheat would be harmful. It is, however, a very valuable addition, and its use is to be strongly recommended, even in single-acting engines that cannot be damaged by superheating the steam ; also, the action of a boiler, fired with coke, is rendered more uniform. Superheating of steam is not, by any means, a new departure, as it was used on the Simpson and Bodman lorry to increase the temperature of steam supplied by the coke-fired flash boiler. On this lorry it is interesting to note that, while provision was made, in the form of a live steam feed-water heater, to prevent the steam becoming too hot, no provision was made, so far as the writer is aware, to prevent the steam from becoming too cold, which must occur, unless precautions are Laken, with any other fuel but oil. The arrangement to do away with the possibility of flooding the boiler, was described on pages 141 and 142 of the issue of October 18th. Exhaust-steam feed-water heaters are well known, but are not used to the extent that they might be, the heaters that are fitted being, generally, very small and inefficient. The whole of the heat absorbed from the exhaust steam by the feed water is pure gain, and a direct means of reducing the fuel consumption.

In the plant shown in Fig. 7, the water from the engine pump lirst passed through the feed-water heating coil around the fire-box of the flash-boiler. As this boiler was fired by oil, very little heat would here be absorbed by the water, but in a coke-fired boiler this arrangement would be a valuable one. The water then flowed to the exhaust feed heater, and, from thence, to the live steam heater, finally entering the boiler at the top coil, as described : in a coke-fired boiler, the water would enter the exhaust feed heater first, or the heat gained in the fire-box coil would be lost. The boiler consisted of ten coils of nickel-alloy steel tube, each coil being 33 feet long, whilst a feed-heating coil, 3o feet in length, was placed inside the fire-box. The overall size of the boiler was height, 3 feet i inch; length, 3 feet 4 inches; and width, i foot 9 inches. The steam pressure was 5501b. on the square inch, and the generator was tested, under a cold water pressure, to 4,000lh. on the square inch. The burners were lighted 10 minutes, at full power, before any water was introduced into the generator, which was then, at its lower portion, a dull-red heat. With the feed water having a temperature of 55deg. Fahrenheit, the boiler was found, using exhaust-steam feed heater only, to evaporate

1,30911). of water per hour to swam of 800deg. Fahrenheit superheat. Taking the second hour of test, in order to eliminate any errors of consumption of the oil used in heating the generator, the evaporation per lb. of fuel was r4.21b., or r5.41b. per square foot of heating surface, the total heating surface of boiler being 85 square feet. The introduction of the live-steam feed-water heater shown in Fig. z considerably improved these results, as, after allowing for the fuel used for the initial heating of the generator, the evaporation per lb. of fuel rose to 18.51b., whilst the evaporation per square foot of heating surface increased to 2o.31b. Under this triple feed-water heating system, the feed water entered the generator coils at a temperature of 45odeg. Fahrenheit.

It will be seen, therefore, that, as with even small engines using highly superheated steam, the consumption can be reduced to 131b. of steam per h.p. per hour, it is particularly possible for the steam engine to compete successfully with the internal-combustion engine, using the same fuel. There has never been any attempt made to condense the steam on lorries, for the very simple reason that the water could not, with ordinary boilers, be used over again. The exhaust is generally taken into a flue, where it is superheated by the waste gases, and so passes invisibly into the atmosphere. It it doubtful whether a condenser of sufficient size to be of any value could be fitted to an ordinary lorry using wet steam. Superheated steam has one great advantage over wet steam, inasmuch as that it can be readily condensed. This fact can be easily understood, because if equal volumes of wet and superheated steam be taken, it will be found that the latter will,

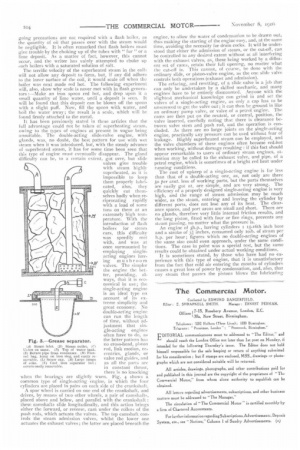

probably, only A weigh one quarter the former, and it can, therefore, be condensed easily in a condenser which could not possibly deal with the same volume of wet steam. To take advantage of the fact in the case of a lorry fitted with an ordinary boiler and superheater, it is necessary to obtain a trustworthy grease separaior. It is, by no means, an easy thing to find a suitable oil separator, as, when some of the best types are reduced in size sufficiently to make them applicable for small steam boil ers, they are inefFig. 2.—Live steam feed heater.

tea 1' isi

202,1 fective in opera(.1, 'Water outlet. (II} Water inlet. It) Live tion. steam inlet. /ID) Steam outlet. (E) Weldless Another g r ea t steel feed heating coil. tF) Cast steel feed

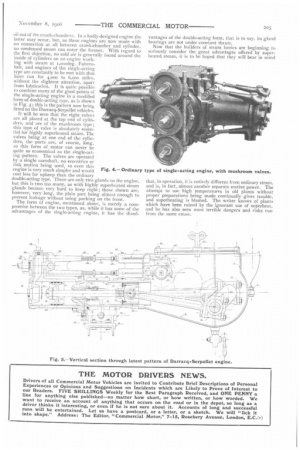

trouble is to get the drivers to clean the oil filter periodically. The writer tried every form of grease separator that could be adopted on steam cars with ordinary boilers, in order to remove the great drawback of incescessant replenishing of water by returning the condensed steam, but had to abandon the idea, as, sooner or later, priming occurred. The best results were obtained with Ow simple arrangement, shown in Fig. 3; this consisted of a box filled with large lumps of coke. The exhaust steam, on its way from engine to condenser, was passed through this box, whilst the return from condenser to tank was passed through a flannel bag hanging on the tank itself. The coke had to be renewed about twice a week, and a clean flannel bag was fitted on every other day. The fore going precautions are not required with a flash boiler, as the quantity of oil that passes over with the steam would be negligible. It is often remarked that flash boilers must give trouble by the choking up of the tubes with " fur" or a lime deposit. As a matter of fact, however, this cannot occur, and the writer has vainly attempted to choke up such boilers with a saturated solution of salt.

The terrific velocity of the superheated steam in the coils will not allow any deposit to form, but, if any did adhere to the inner surface of the coil, it would scale off when the boiler was next made red hot. The following experiment will, also, show why scale is never met with in flash generators :—Make an iron spoon red hot, and drop upon it a small quantity of lime water, until a deposit is seen. It will be found that this deposit can be blown off the spoon with a slight puff. Now, fill the spoon with water, and boil the water away ; the result is a scale, which will be found firmly attached to the metal.

It has been previously stated in these articles that the full advantage could not be taken of superheating steam, owing to the types of engines at present in vogue being unsuitable. The double-acting slide-valve engine, with glands, was, no doubt, the best pattern for use with wet steam when it was introduced, but, with the steady advance of superheated steam, it has for some time been seen that Ibis type of engine must eventually disappear. The gland difficulty can be, to a certain extent, got over, but slide valves give trouble with steam highly superheated, as it is impossible to keep them properly lubricated, also, they quickly cut themselves badly when reciprocating rapidly with a load of some tons on them at an extremely high temperature. With the introduction of flash boilers for steam cars, this difficulty was speedily met with, and was at once surmounted by employing singleacting engines having mushroom valves. The simpler the engine the better, providing, always, that it is economical in use ; the single-acting engine is an ideal type on account of its ex

2e5-3 treme simplicity and great economy. No double-acting engine can run the length of time, without adjustment that single-acting engines often have to do, as the latter pattern has no cross-head, piston rod, link motion, eccentrics, glands, or valve rod guides, and as all the parts are in constant thrust, there is no knocking when the bearings are slightly worn. Fig. 4 shows a common type of single-acting engine, in which the four cylinders are placed in pairs on each side of the crankshaft.

A spur wheel is carried on one end of the crankshaft, and drives, by means of two other wheels, a pair of camshafts, placed above and below, and parallel with the crankshaft : these camshafts slide longitudinally, and this action brings either the forward, or reverse, cam under the rollers of the push rods, which actuate the valves. The top camshaft controls the steam admission valves, whilst the lower one actuates the exhaust valves ; the latter are placed beneath the

Fig. 3.—Grease separator.

(.4) Steam inlet. (B) Stettin outlet. (1) th.ion on same. (7)) Top of water tank. (E) Return pipe from condenser. (H) Flan• nd bn, hung on iron ring, rind easily re. movable. (Li Screw cap. (M) Large lumps of coke. (N) Cast iron separator box ; covers easily removable. engine, to allow the water of condensation to be drawn out, thus making the starting of the engine easy, and, at the same time, avoiding the necessity for drain cocks. It will be understood that either the admission of steam, or the cut-off, can be controlled to any desired extent without at all interfering with the exhaust valves, as, these being worked by a different set of cants, retain their full opening, no matter what the cut-off is. This cannot, of course, be done with the ordinary slide, or piston-valve engine, as the one slide valve controls both operations (exhaust and admission). The refacing, and resetting, of a slide valve is a job that can only be undertaken by a skilled mechanic, and many engines have to be entirely dismounted. Anyone with the slightest mechanical knowledge can grind in and set the valves of a single-acting engine, as only a cap has to be unscrewed to get the valve out; it can then be ground in like an ordinary pump valve, or valve of a petrol engine. The cams are then put on the neutral, or central, position, the valve inserted, carefully noting that there is clearance between valve stem and push rod, and the operation is concluded. As there are no large joints on the single-acting engine, practically sny pressure can be used without fear of leakage. Highly superheated steam can be employed, and the valve chambers of these engines often become red-hot when working, without damage resulting : if this fact should appear remarkable to users of ordinary steam engines, attention may be called to the exhaust valve, and pipe, of a petrol engine, which is sometimes of a bright red heat under running conditions.

The cost of upkeep of a single-acting engine is far less than that of a double-acting one, as, not only are there so per cent. less of working parts, but the parts themselves are easily got at, are simple, and are very strong. The efficiency of a properly designed single-acting engine is very high, and the range of steam admission may be much wider, as the steam, entering and leaving the cylinder by different ports, does not lose any of its heat. The clearance spaces, and port areas are small and short. There are no glands, therefore very little internal friction results, and the long piston, fitted with four or five rings, prevents any steam passing, no matter what the pressure is. An engine of sh.p., having cylinders r is-16th inch bore and a stroke of 31 inches, consumed only to:b. of steam per h.p. per hour; figures which no double-acting engines of the same size could even approach, under the same conditions. The case in point was a special test, but the same results could be obtained under actual working conditions. It is sometimes stated, by those who have had no experience with this type of engine, that it is unsatisfactory from the fact that cold air entering the mouths of cylinders causes a great loss of power by condensation, and, also, that any steam that passes the pistons blows the lubricating

oil out of the crank-chambers. In a badly-designed engine the latter may occur, but, as these engines are now made with no connection at all between crank-chamber and cylinder, no condensed steam can enter the former. With regard to the first objection, no cold air is generally found around the inside of cylinders on an engine working with steam at 1,000deg. Fahrenheit, and engines of the single-acting type are constantly to be met with that have run for 4,000 to 6,000 without the slightest attention, apart from lubrication. It is quite possible to combine many of the good points of the single-acting engine in a modified form of double-acting type, as is shown in Fig. 5; this is the pattern now being fitted on the Darracq-Serj)ollet vehicles. It will be seen that the eight valves are all placed at [he top end of cylinders, and are of the mushroom type ; this type of valve is absolutely essential for highly superheated steam. The valves being at one end of the cylinders, the ports are, of course, long, so this form of motor can never be quite so economical as the single-acting pattern. The valves are operated by a single camshaft, no eccentrics or link motion being used, so even this engine is very much simpler and would cost less for upkeep than the ordinary double-acting type. There are only two glands on the engine, but this is two too many, as with highly superheated steam glands become very hard to keep right; those shown are, however, very long, the plain part being almost enough to prevent leakage without using packing on the front.

The form of engine, mentioned above, is merely a compromise between the two types, as, while it has some of the advantages of the single-acting engine, it has the disad

Fig. 4.— Ordinary vantages of the double-acting form, that is to say, its gland bearings are not under constant thrust. Now that the builders of steam lorries are beginning to seriously consider the great advantages offered by superheated steam, it is to be hoped that they will bear in mind that, in operation, it is entirely different from ordinary steam, and is, in fact, almost another separate motive power. The attempt to use high temperatures in old plants without proper preparations being made continually gives trouble, and superheating is blamed. The writer knows of plants which have been ruined by the ignorant use of superheat, and he has also seen most terrible dangers and risks run from the same cause.