IDEAL FOR BULK TRANSPORT OF LIQUIDS.

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

The Easy Riding of the Six-wheeler an Important Factor with Liquids that Should Not be Churned. Tar Transport in Large Quantities.

1/ ULK transport has unquestionably been given a great impetus by the introduction of the sixwheeler, and particularly of the rigid-frame type, because a substantial load may be carried on a vehicle of a moderate overall length. There are certain liquids that can be transported in bulk with considerable gain in economy, such as milk, beer, tar, etc., and where it is thought undesirable that the liquid should be churned or subjected to a surging action, the rigid-frame sixwheeler is not to be equalled, for the support of the extra axle is such that many pot-holes and depressions in the road surface are completely bridged and the jolting received by the axles through road inequalities are not transmitted to the frame or to the load.

In the transport of tar the rigid-frame six-wheeler has thus been a distinct accession, and in the same work the steam vehicle offers certain advantages, mainly because of the availability of the heat from the boiler at all times.

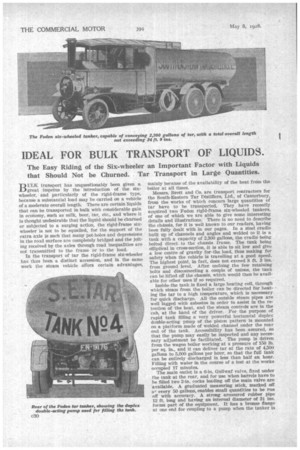

Messrs. Brett and Co. are transport contractors for the South-Eastern Tar Distillers, Ltd., of Canterbury, from the works of which concern large quantities of tar have to be transported. They have recently acquired two Foden rigid-frame six-wheeled tankers, of one of which we are able to give some interesting details and illustrations. There is no need to describe the chassis, for it is well known to our readers, having been fully dealt with in our pages. In a steel cradle built up of channels and angles and welded to it is a tank with a capacity of 2,300 gallons, the cradle being bolted direct to the chassis frame. The tank being elliptical in cross-section, it is able to sit low and give a low centre of gravity for.the load, thus making for safety when the vehicle is travelling at a good speed. The highest point, in fact, does not exceed 8 ft. 3 ins. from ground level. After undoing the few retaining bolts and disconnecting a couple of unions, the tank can be lifted off the chassis, which would then be available for other uses if so required.

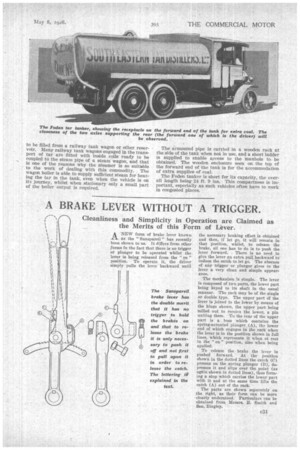

Inside, the tank is fixed a large heating coil, through which steam from the boiler can be directed for heating the tar to a high temperature, which is necessary for quick discharge. All the outside steam pipes are well lagged with asbestos in order to assist in the retention of the heat, and the steam controls are in the cab, at the hand of the driver. For the purpose of rapid tank filling a very powerful horizontal duplex double-acting pump of the piston pattern Is mounted on a platform made of welded channel under the rear end of the tank. Accessibility has been assured, so that the pump may easily be inspected and any necessary adjustment be facilitated. The pump is driven from the wagon boiler working at a pressure of 150 lb. per sq. in., and it can deliver tar at the rate of 4,500 gallons to 5,000 gallons per hour, so that the full tank can be entirely discharged in less than half an hour. Filling with water in the course of a test at the works occupied 17 minutes.

The main outlet is a 6-in. Gullwaf valvs, fixed under the tank at the rear, and for use when barrels have to be filled two 2-in, cocks leading off the main valve are available. A graduated measuring stick, marked off at every 50 gallons, enables small quantities to be run off with accuracy. A strong armoured rubber pipe 12 ft. long and having an internal diameter of 2i ins. forms part of the equipment. It has a bronze flange at one end for coupling to a pump when the tanker is to be filled from a railway tank wagon or other reservoir. Many railway tank wagons engaged in the transport of tar are fitted with inside coils ready to be coupled to the steam pipe of a steanf wagon, and that is one of the reasons why the steamer is so suitable to the work of dealing with this commodity. The wagon boiler is able to supply sufficient steam for heating the tar in the tank, even when the vehicle is on its journey, whilst when stationary only a small part of the boiler output is required. The armoured pipe is carried in a wooden rack at the side of the tank when not in use, and a short ladder is supplied to enable access to the manhole to be obtained. The wooden enclosure seen on the top of the forward end of the tank is for the accommodation of extra supplies of coal.

The Foclen tanker is short for its capacity, the overall length being 24 ft. 9 ins. This compactness is important, especially as such vehicles often have to work in congested places.