roskold gets prize For keeping so cool

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

RAVEN TASKER (Sheffield) Ltd has won a Design Council ward with its Taskold semi-trailer, as adapted for the Danish icon industry, writes BILL BROCK.

Denmark exports more than )0,000 tons of bacon each ..ar in specially built refrigerted vans. Prior to 1976, ngle-axle ten-ton capacity ailers were operated. Devepment of thermal insulation 'id construction techniques, sing unconventional matrials in some instances, Bowed production of 16-ton apacity trailers increasing the ayload/tare ratio from 2.65 to to 3 to 1.

At the same time this cornlied with the UK overall limit of 32 tons and giving a rollon /roll-off capability needed for land and sea transportation.

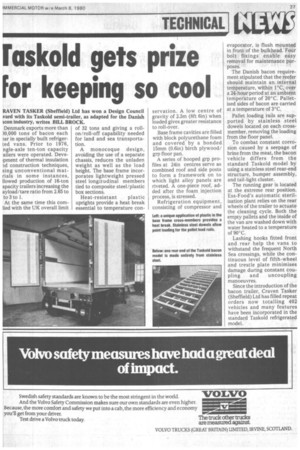

A monocoque design, avoiding the use of a separate chassis, reduces the unladen weight as well as the load height. The base frame incorporates lightweight pressed steel longitudinal members tied to composite steel/plastic box sections.

Heat-resistant plastic uprights provide a heat break essential to temperature con servation. A low centre of gravity of 2.5m (8ft 6in) when loaded gives greater resistance to roll-over.

Base frame cavities are filled with block polyurethane foam and covered by a bonded 15mm (0.6in) birch plywood/ grp floor pan.

A series of hooped grp profiles at 24in centres serve as combined roof and side posts to form a framework on to which light alloy panels are riveted. A one-piece roof, added after the foam injection process, is stressed.

Refrigeration equipment, consisting of compressor and evaporator, is flush mounted in front of the bulkhead. Four bolt fixings enable easy removal for maintenance purposes.

The Danish bacon requirement stipulated that the reefer should maintain an internal temperature, within 1°C, over a 24-hour period at an ambient temperature of 20°C. Palletised sides of bacon are carried at a temperature of 3°C.

Pallet loading rails are supported by stainless steel dowels located on each crossmember, removing the loading from the floor panel.

To combat constant corrosion caused by a seepage of brine from the meat, the bacon vehicle differs from the standard Taskold model by using a stainless steel rear-end structure, bumper assembly, and tail-light cluster.

The running gear is located at the extreme rear position. Ess-Food's automatic sterilisation plant relies on the rear wheels of the trailer to actuate the cleaning cycle. Both the empty pallets and the inside of the van are washed down with water heated to a temperature of 90°C.

Lashing hooks fitted front and rear help the vans to withstand the frequent North Sea crossings, while the continuous level of fifth-wheel and trestle plate minimises damage during constant coupling and uncoupling manoeuvres.

Since the introduction of the bacon trailer, Craven Tasker (Sheffield) Ltd has filled repeat orders now totalling 402 vehicles and many features have been incorporated in the standard Taskold refrigerated model.