WAYS AND . MEANS.

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

Interesting Contributions from Our Driver and Mechanic Readers.

A Simple Method of Aligning Pistons.

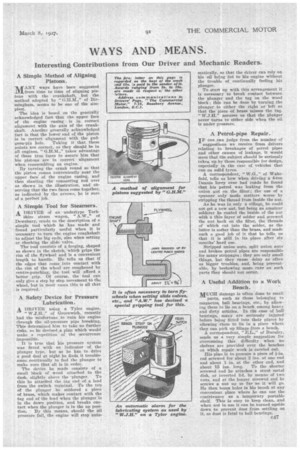

IVITANY ways have been suggested It &from time to time of aligning pistons with the crankshaft, but the method adopted by " G.U.M.," of Birmingham, seems to be one of the simplest.

The idea is based on the generally acknowledged fact that the upper face of the engine easing is in correct alignment with the axis of the crankshaft. Another generally acknowledged fact is that the lower end of the piston is in correct alignment with the gud geon-pin hole. Taking it that these points are correct, as they should be in all engines, " G.H.M.," takes advantage of these true faces to assure him that his pistons are in correct alignment when reassembling an engine.

By turning the crank round so that the piston comes conveniently near the upper face' of the engine casing, and then slanting the connecting rod over SIN shown in the illustration, and observing that the two faces come together, as indicated by the arrows, he is sure of a perfect job.

A Simple Tool for Steamers. A DRIVER of an .undertype York

shire steam wagon, " A.W.," of Dewsbury, Fends us the description of a simple tool which he has made and found particularly useful when it is necessary to turn the engine crankshaft to adjust the big ends, also when setting or checking the slide valve.

The tool eonsists of a forging, shaped as shown in the sketch, which grips the rim of the flywheel and is a convenient length to handle. He tells us that if the edges that come into contact with the rim of the wheel are roughened by centre-punching, the tool will afford a better grip. Of course, the tool can only give a step by step movement to the wheel, but in most cases this is all that is required.

A Safety Device for Pressure Lubrication.

A. DRIVER using a Tyler engine,

" of Greenwich, recently had the misfortune to ruin his engine through the oil-pressure pipe breaking. This determined him to take no further risks, so he devised a plan which would make a repetition of the occurrence impossible.

It is true that his pressure system was fitted with an indicator of the plunger type, but as he has to drive a good deal at night he finds it troublesome_continnally to feel the plunger to make sure that all is in order.

The device he made consists of a small block of wood attached to the dash, slightly above the -plunger. To this he attacked the tag end of a lead from the switch terminal. To the top of the plunger he soldered a piece of brass, which makes contact with the tag end of the lead when the plunger is in the down position, and breaks Cantact when the plunger is in the up posi

tion: By this means, should the oil pressure fail, the engine will stop auto

matically, so that the driver can rely on his oil being fed to his engine without the trouble of continually feeling his plunger.

To start up with this arrangement it is necessary to break contact between the plunger and the tag on the wood block ; this can be done by turning the plunger to either the right or left so that the piece of brass misses the tag.

" assures us that the plunger never turns to either side when the oil is under pressure.

A Petrol-pipe Repair.

IF one can judge from the number of suggestions we receive from drivers relating to breakages of petrol pipes and other causes of leakage, it would seem that the subject should be seriously taken up by those responsible for design, especially in the case of vehicles that run on solid tyres.

A correspondent, " W.G.," of Wakefield, tells us how when driving a 4-ton Dennis lorry over bad roads he found that his petrol was leaking from the union nut on the filter ; the use of a spanner only made matters worse by stripping the thread from inside the nut.

As he was in only a village, he could not get a new nut, but being an amateur solderer he coated the inside of the nut with a thin layer of solder and_ screwed the nut back on the filter, the threads of which cut into the solder, as the latter is softer than the brass, and made such a good job of it that he tells us that it is still in its place after six months' hard use.

Stripped union nuts, split union nuts and .broken petrol pipes are responsible for many stoppages ; they are only small things, but they cause delay as often as bigger troubles, and, being preventable, by bestowing more care on such parts they should not occur.

'A Useful Addition to a Work Bench.

MUCH damage is often done to small parts, such as those belonging to magnetos, ball bearings, etc., by allowing them to lie on a bench among heavy and dirty articles. In the case of ball bearings, many are seriously injured before being fitted into their places by allowing them to lie in a place where they can pick up filings from a bench.

A correspondent, "E.L„" of Burnley, sends us a very simple suggestion for overcoming this difficulty when no shelves are provided over the benches on which repair work is carried out.

His plan is to procure a piece of fin. rod screwed for about 2 ins, at one end and about 1 in. at the other end, and

about 15 ins. long. To the shorter screwed end he attaches a stout metal dish, or inverted lid, by means of two nuts, and at the longer screwed end he screws a nut up so far as it will go. He then bores holes in his bench at any Convenient place where he can use the contrivance as a temporary portable shelf. This is easy to keep clean, and when not in use it can be turned upside down to prevent dust from settling on It, as dust is fatal to ball bearings.