EIGHT-LEGGER WEIGHS IN

Page 121

Page 122

Page 123

Page 124

If you've noticed an error in this article please click here to report it so we can fix it.

If kerbweight and price are less important to operators than handling and performance, M-B's latest tipper will carve a niche in Britain's tough eight-wheeler market

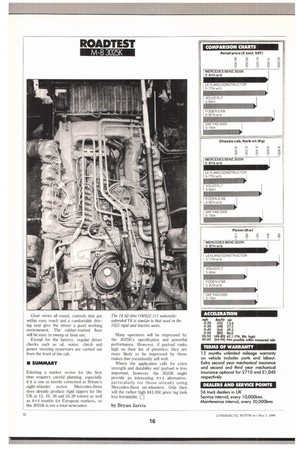

• Mercedes-Benz's new entry into the eight-wheeled tipper league, the 3025K, extends and completes its range of rigid tipping chassis. The 3025K allows the manufacturer to compete at 30.49 tonnes and complements its existing 13, 16.26, and 24.39 GVW models.

The new model has the performance and pedigree that will interest dedicated Mercedes-Benz operators who have the advantage of user experience, already ' stock M-B parts and enjoy single-service support. Whether it will attract uninitiated buyers remains to be seen.

Certainly, home manufacturers are already hard pressed to maintain a halfshare of the small but lucrative UK eightwheeler markeL Mercedes-Benz will take little comfort from the knowledge that operators of British-built or other imported chassis may be less inclined to change allegiance and risk complicating still further their back-up support.

Nevertheless, Mercedes-Benz confidently predicts it will take a 10 per cent share of an 8x4 market sector that increased in 1985 by 10.7 per cent over the previous year.

Sales of eight wheelers last year amounted to 2,033 units, with leaders Leyland and Volvo sharing just over half and Foden, Oaf, ERF and MAN taking 11, 9.7, 7.5 and 7.3 per cent respectively. Seddon-Atkinson and lveco also accounted for another five and 4.7 per cent. Mercedes-Benz will only find its 10 per cent share by taking it from these others. Certainly from the way it performed over our new tipper test route, the 3025K has all the credentials necessary to put it in with a shout.

Mercedes-Benz's eight-wheeler chassis originates from the nearest standard (6x4) specification possible from within the volume production at Daimler-Benz's Worth factory. It is then taken to its Arbon, Switzerland, conversion facility. There, the second steered axle and extra hydraulic steering pump are added before the vehicle returns to Worth for its completion.

In chassis cab form the 3025K maintains Mercedes-Benz's tradition of a sturdy but heavy design. It weighs in at 8,630kg — 570kg heavier than a comparable Foden S108 and 430kg more than the Leyland Constructor 8x4.

• PERFORMANCE

M-B expects considerable interest from users of its 6x4 tipping and mixer chassis where there is much common componentry. The 3025K has a driveline that is already familiar to British operators. Its 14.62-litre 0M422.111 naturally-aspirated diesel is similar to that used in the 1625 rigid drawbar and tractive unit and produces a net power output of 184kW (246hp) at 2,300rpm.

This gives it the high, 6.03kW/tonne (8.23hp/ton) power-to-weight ratio required at the 30.49 tonnes gross vehicle limit as well as a smooth on-road performance, particularly on motorways.

There is a choice of transmission, with the standard Mercedes-Benz G4/95-7/11 seven-speed box or the optional 2F 16S112GP Ecosplit unit as fitted on the test vehicle. Both gearboxes are synchro mesh, but we prefer the latter which is well matched to the 3025K. It is not only smooth with easy gear selection, it also gives a wider choice of ratios than the seven-speeder to suit all terrains and conditions.

With the standard 4.3:1 final-drive ratio and 11R 22.5 tyres, the Ecosplit's direct top gear gives a maximum geared speed of 1021on/h. However, its range of ratios seems compatible with the torque characteristics of Mercedes-Benz's big V8, and when running on A roads between the 40 and 50mph limits the engine revs sit comfortably in the middle of the green segment of the rev counter for optimum economy.

Moving away from rest on level ground requires very few changes. Beginning with fourth, through the double-H range change to sixth, seventh and eighth, the high split is needed only on eighth. Slightly steeper starts mean taking off either in third direct or, at worst, second high.

The tipper was able to take the 16.5 per cent (1 in 6) Edge Hill climb on the A422 west of Banbury in third direct with plenty of power in hand.

Indeed, under rainy, blustery conditions the eight-wheeler returned its best fuel economy of 40.3lit/1(101an at 52.54 km/h (7.01mpg at 32.68mph) around the A-road section.

As could be expected, however, motorway work took its toll of the fuel. Here the 3025K's fuel consumption increased to 46.091it/100km (6.13mpg), but at the much faster average speed of 78.58km/h (48.88mph).

This gave an overall return for the entire route of 42.481it/100kin at an average speed of 6 0.2 3km/h (6.6 5mpg at 37.46mph), figures which will achieve more significance in the months ahead as more tippers are subjected to our new test route.

• BRAKING

Eight-wheelers are notoriously tough on their brakes and here the 3025K, with its full-air sytem, had mixed fortunes. Rolling road brake test figures showed efficiencies that are not among the best, while a full pressure stop at 68km/h on a damp patchy surface had the second steering axle brakes locking on fairly early.

On checking this at M-B's Waketield workshop after the test, the linkage for the load sensing valves was found to be sticking over-centre, preventing it from operating consistently.

Around the route however, the brakes performed quite well. The pedal required plenty of firm pressure but pulled the vehicle up straight every time without fuss. To Mercedes-Benz's credit, the 1/8 is fitted with a most efficient exhaust brake system as standard. The device, which comprises of a flap valve at the rear of the exhaust manifold on each bank, is most welcome on long downhill runs. In addition, it conserves fuel by returning the Bosch injection pump rack towards the nodelivery position.

It also doubles as the engine stop, the only drawback being an extra noise penalty, but a few decibels is a small sacrifice for such effectiveness.

• HANDLING On the main roads the 3025K's suspension behaves superbly, whether on sharp bends, roundabouts or extreme cambers. Mercedes-Benz fits straight-beam front axles and hub-reduction axles with a standard interlock at the rear. With the brake chambers mounted above the 'flattened' differential casings and out of harm's way, a high 354mm (14in) ground clearance is achieved. This is an important factor which makes working over rough ground less risky.

Around MIRA's ride and handling circuit the 3025K's parabolic front springs and two-spring bogie coped extremely well, helped by the anti-roil bar.

On the quarry site, too, the eight-legger showed that it is capable of working well over rough ground, articulating well under full load but without excessive body roll.

Extra power assistance for the two steered axles is provided by a second pump, mounted on the rear of the ZF gearbox. This supplements the enginemounted pump and ensures hydraulic assistance should the engine fail on the move. Both are ZF units.

The 3025K Mercedes-Benz recirculat

ing ball steering with integral power assistance operates easily enough, aided by the traditionally over-large wheel, although on low engine revs a slight hesitancy is noticeable within the system.

A kerb-to-kerb turning circle of 24.87m (Sift Sin) is, however, probably the largest of any eight-wheeler we have ever tested.

This is 1, lm (3ft 7in) greater than those of the Daf and Foden models tested last year (CM May 11) and 3.1m (10ft 2in) greater than that of the Leyland Scammell Constructor tested live years ago (CM May30, 1981).

• CAB COMFORT Any extra time spent manoeuvring is barely noticeable in a well-trimmed day cab Lhat has been carefully arranged for driver convenience and high safety standards. Clear views all round, controls that are within easy reach and a comfortable driving seat give the driver a good working environment. The rubber-matted floor will be easy to sweep or hose out.

Except for the battery, regular driver checks such as oil, water, clutch and power steering reservoirs are carried out from the front of the cab.

• SUMMARY

Entering a market sector for the first time requires careful planning, especially if it is one as keenly contested as Britain's eight-wheeler sector. Mercedes-Benz does already produce rigid tippers for the UK at 13, 16, 26 and 24.39 tonnes as well as 8x4 models for European markets, so the 3025K is not a total newcomer. Many operators will be impressed by the 3025K's specification and powerful performance. However, if payload ranks high on their list of priorities, they are more likely to be impressed by those makes that consistently sell well.

Where the application calls for extra strength and durability and payload is less important, however, the 3025K might provide an interesting 8x4 alternative, particularly for those already using Mercedes-Benz six-wheelers. Only then will the rather high £41,050 price tag look less formidable.

by Bryan Jarvis