Packing them in at Torbay

Page 57

Page 58

Page 59

Page 60

Page 63

Page 64

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

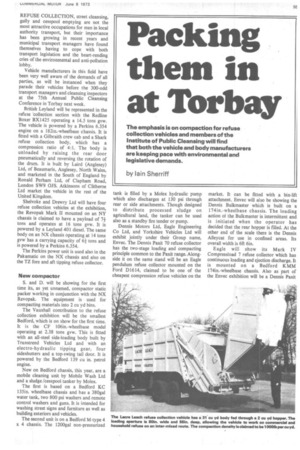

The emphasis is on compaction for refuse collection vehicles and members of the Institute of Public Cleansing will find that both the vehicle and body manufacturers are keeping pace with environmental and legislative demands.

by lain Sherriff

REFUSE COLLECTION, street cleansing, gully and cesspool emptying are not the most attractive occupations for men in local authority transport, but their importance has been growing in recent years and municipal transport managers have found themselves having to cope with both transport legislation and the heart-rending cries of the environmental and anti-pollution lobby.

Vehicle manufacturers in this field have been very well aware of the demands of all parties, as will be instanced when they parade their vehicles before the 300-odd transport managers and cleansing inspectors at the 75th Annual Public Cleansing Conference in Torbay next week.

British Leyland will be represented in the refuse Collection section with the Redline Boxer BX1425 operating a 14.5 tons gvw. The vehicle is powered by a Perkins 6.354 engine on a 182in.-wheelbase chassis. It is fitted with a Gilbraith crew cab and a Shark refuse collection body, which has a compression ratio of 4:1. The body is unloaded by raising the rear door pneumatically and reversing the rotation of the drum. It is built by Laird (Anglesey) Ltd, of Beaumaris, Anglesey, North Wales, and marketed in the South of England by Ronald Perham Ltd, of Clapham Road, London SW9 WS. Atkinsons of Clitheroe Ltd market the vehicle in the rest of the United Kingdom.

Shelvoke and Drewry Ltd will have four refuse collection vehicles at the exhibition, the Revopak Mark II mounted on an NY chassis is claimed to have a payload of 7+ tons and operates at 16 tons gvw. It is powered by a Leyland 401 diesel. The same body on an NX chassis operating at 14 tons gvw has a carrying capacity of 6+ tons and is powered by a Perkins 6.354.

The Perkins power unit is used also in the Pakamatic on the NX chassis and also on the TZ fore and aft tipping refuse collector.

New compactor S. and D. will be showing for the first tune its, as yet unnamed, compactor static packer working in conjunction with the NX Revopak. The equipment is used for compacting materials into 2 cu yd bins.

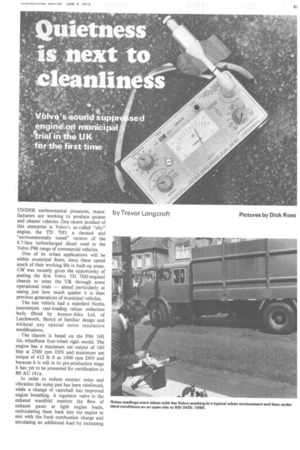

The Vauxhall contribution to the refuse collection exhibition will be the smallest Bedford, which is on show for the first time. It is the CF 106in.-wheelbase model operating at 2.38 tons gvw. This is fitted with an all-steel side-loading body built by Transtrend Vehicles Ltd and with an electro-hydraulic tipping gear, four sideshutters and a top-swing tail door. It is powered by the Bedford 139 cu in. petrol engine.

New on Bedford chassis, this year, are a mobile cleaning unit by Mobile Wash Ltd and a sludge/cesspool tanker by Molex.

The first is based on a Bedford KC 135in. wheelbase chassis and has a 380ga1 water tank, two 800 psi washers and remote control washers and guns. It is intended for washing street signs and furniture as well as building exteriors and vehicles.

The second unit is on a Bedford M-type 4 x 4 chassis. The 1200gal non-pressurized tank is filled by a Molex hydraulic pump which also discharges at 130 psi through rear or side attachments. Though designed to distribute processed sludge on agricultural land, the tanker can be used also as a standby fire tender or pump.

Dennis Motors Ltd, Eagle Engineering Co Ltd, and Yorkshire Vehicles Ltd will exhibit jointly under their Group name, Envec. The Dennis Paxit 70 refuse collector has the two-stage loading and compacting principle common to the Paxit range. Alongside it on the same stand will be an Eagle pendulum refuse collector mounted on the Ford D1614, claimed to be one of the cheapest compression refuse vehicles on the market. It can be fitted with a bin-lift attachment. Envec will also be showing the Dennis Bulkmaster which is built on a 174in.-wheelbase chassis. The loading action of the Bulkmaster is intermittent and is initiated when the operator has decided that the rear hopper is filled. At the other end of the scale there is the Dennis Alleycat for use in confined areas. Its overall width is 6ft 6in.

Eagle will show its Mark IV Compressload 7 refuse collector which has continuous loading and ejection discharge. It is mounted on a Bedford KMM 174in.-wheelbase chassis. Also as part of the Envec exhibition will be a Dennis Paxit Major IIIC refuse collector which is powered by the Perkins 6.354.

The Ford Motor Co Ltd is to display the S. and D. Revopak refuse collector on the DT2014 178in.-wheelbase chassis which is powered by the six-litre turbocharged 140 bhp diesel. The 22 cu yd body has a carrying capacity of 10 tons. On a Transit 115 Ford has mounted the Transtrend refuse collector. This is built by Transtrend Vehicles Ltd of Richmond, Surrey.

Using the D1210 156in.-wheelbase Ford is also to exhibit a Glover, Webb and Liversidge Musketeer 19 which has 19 cu yd of air space and a compacting capacity of about 60 cu yd. It is powered by the Ford six-litre diesel and has a seven-man Reliant-built glassfibre crew-cab.

Chrysler (UK) Ltd will be strongly represented on the Glover, Webb and Liversidge stand, where a Musketeer Mark II continuous loading body is fitted to a Karrier VC 8 with a 162in. wheelbase. The body has 19 cu yd air space and is constructed of aluminium alloy sheets and steel pillars. The vehicle has a gross weight of 13 tons and the carrying capacity is in excess of 6 tons. Stepping down one place in the range, the Karrier VC 7 with a 141in. wheelbase is demonstrated with a Musketeer 15/45 continuous loading refuse collector. This is fitted with a single impellor in the 15yd body. This type of vehicle is particularly suited for sack collection; its gross weight is 12 tons and it will carry 5+ tons. It has a turning circle of 494-ft.

G.W.L. produced a dual tip gravity pack refuse collector back in 1954 and has been doing so ever since. The vehicle on show this year is fitted with an 18 cu yd body with a packer plate and is mounted on a Karrier WC 4 with a 141in. wheelbase and a six-man crew-cab.

Chrysler will also be in evidence on the stand of Johnston Brothers (Engineering) Ltd, of Dorking. This company will show a junior suction sweeper based on a Bantam FB3 98in. wheelbase chassis. It has a 3 cu yd capacity tipping body witla rear doors. The water tank has a capacity of 90gals and is equipped with a filter on the suction side, a low-water warning device and a pressure relief valve. The 16in. brush has a speed range of 30-180 rpm. Arenco-Alite Ltd is to exhibit three bodies on five separate chassis. The KI5 is the intermittent loading type body with a packer plate and has a loading potential of 70 cu yd. It will appear at Torbay on the Dodge K10 50 with a 186in. wheelbase. It is also fitted to the Seddon 13/4 with a 176in. wheelbase. Both of these vehicles are powered by the Perkins 6.354. There is also a Ford D 1614 model with a 179in. wheelbase, which is fitted with a Reliant seven-man crew-cab. The K15 operates on all three vehicles at 16 tons gvw.

Karrier and Seddon will be exhibited fitted with the Norba Screw compaction. The Karrier has a loading potential of 50 cu yd on a VC8 chassis with a 162in. wheelbase and operates at 13 tons gvw. The Seddon is carrying a 70 cu yd body on a 176in. wheelbase and operates at 16 tons gvw. Ailsa Trucks Ltd is to show for the first time the Volvo F86 with a 193in. wheelbase carrying the Norba intermittent rear-loading refuse collection body which CM had on operational trial last month (see page 62 this issue).

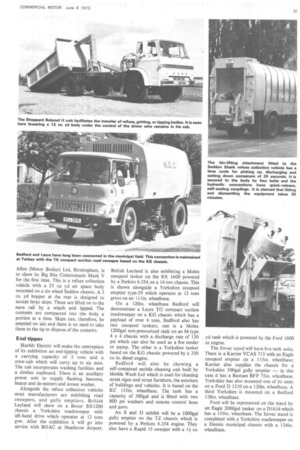

As well as its complete range of Colectomatic refuse collection vehicles, Jack Allen (Motor Bodies) Ltd, Birmingham, is to show its Big Bite Colectomatic Mark V for the first time This is a refuse collection vehicle with a 25 cu yd air space body mounted on a six-wheel Seddon chassis. A 3 cu yd hopper at the rear is designed to accept large skips. These are lifted on to the nave rail by a winch and tipped. The contents are compacted into the body a portion at a time. Skips can, therefore, be emptied on site and there is no need to take them to the tip to dispose of the contents.

End tipper

Harbilt Electric will make the centrepiece of its exhibition an end-tipping vehicle with a carrying capacity of 3 tons and a crew-cab which will carry up to six men. The cab incorporates washing facilities and a clothes cupboard. There is an auxiliary power unit to supply flashing beacons, heater and de-misters and screen washer.

Alongside the refuse collection vehicles most manufacturers are exhibiting road sweepers, and gully emptiers. British Leyland will show on a Boxer BX1200 chassis a Yorkshire roadsweeper with left-hand drive which operates at 12 tons gvw. After the exhibition it will go into service with BOAC at Heathrow Airport. British Leyland is also exhibiting a Molex cesspool tanker on the BX 1600 powered by a Perkins 6.354 on a 16-ton chassis. This is shown alongside a Yorkshire cesspool emptier type-59 which operates at 12 tons gross on an 111in. wheelbase.

On a 120in. wheelbase Bedford will demonstrate a Lacre TG compact suction roadsweeper on a KG chassis which has a payload of over 6 tons. Bedford also has two cesspool tankers, one is a Molex 1200gal non-pressurized tank on an M-type 4 x 4 chassis with a discharge rate of 130 psi which can also be used as a fire tender or pump. The other is a Yorkshire tanker based on the KG chassis powered by a 330 cu in. diesel engine.

Bedford will also be showing a self-contained mobile cleaning unit built by Mobile Wash Ltd which is used for cleaning street signs and street furniture, the exteriors of buildings and liehicles. It is based on the KC 135 in. wheelbase. The tank has a capacity of 380ga1 and is fitted with two 800 psi washers and remote control hose and guns.

An S and D exhibit will be a 1000gal gully emptier on the TZ chassis which is powered by a Perkins 6.354 engine. They also have a Rapid 15 sweeper with a I+ Cu yd tank which is powered by the Ford 1600 cc engine.

The Envec stand will have five tank units. There is a Karrier VCAS 715 with an Eagle cesspool emptier on a 115in. wheelbase; Karrier also supplies the chassis for a Yorkshire 500gal gully emptier — in this case it has a Bantam BFF 75in. wheelbase. Yorkshire has also mounted one of its units on a Ford D 1210 on a 120in. wheelbase. A third Yorkshire is mounted on a Bedford 138in. wheelbase.

Ford will be represented on the stand by an Eagle 2000gal tanker on a D1614 which has a 159in. wheelbase. The Envec stand is completed with a Yorkshire roadsweeper on a Dennis municipal chassis with a 124in. wheelbase. The Multilift stand will be exhibiting a Dodge KT 900 with a Multilift AOA 760 installed. This equipment has a 16-ton lifting capacity. Multilift will also be showing an AOA 400 which has a lifting capacity of 8 tons; this equipment is installed on a Ford 1311 with a 156in. wheelbase.

Skip loader Sheppard Meiller is to be demonstrated on a Ford D 1614 with a 147in. wheelbase. The skip loader can be replaced with either road gritters or tankers to be used in conjunction with the Rolonof Two bulk gritters from the Charrold range will be on display; they have 44 cu yd bodies and are mounted on a Bedford RL 4 x 4 and a Commer VC 7.

Rolba Ltd is to demonstrate its R 200 which is built on a special chassis complete with purpose-built cab and powered by a 66 hp air-cooled VW petrol engine.

Smiths Electric Vehicles Ltd will have four Cabacs on display, all of them due to go into service immediately after the exhibition. The one for the London Borough of Harringey is powered by a 30-cell battery of 329 Ah. The body is a flat platform covered with a canopy with hinged doors at the rear which are tippable. A 34 cu yd Cabac 75 destined for Redbridge has a five-man crew cab. It is designed for side loading and end tipping and is powered by a 24-cell 319 amp battery.

Bin carrier Glasgow will take delivery of the third vehicle, a Cabac bin carrier with a similar power unit to the Redbridge vehicle. It also is a bin carrier capable of carrying 15 glassfibre bins which measure 24ft x 20ft x 24ft. Its 24-cell battery gives 376 Ah.

A side loading, end tipping body is mounted on a Cabac 65 for delivery to Sunderland. It is powered by a 30-cell battery producing 292 Ah.

Among the tipping vehicles British Leyland's Guy Big J6 6 x 4 tipper operates at 24 tons gross. The body is an Edbro bucket loader fitted with the Edbro ELB3 gear and has a carrying capacity of 14 Cu yd.

Edbro has also been favoured with Ford and has a three-way 14ft 6in.-long bolted alloy body mounted on a D 1614. This is a 147in. wheelbase and the Ford is powered by a 140 hp six-litre turbocharged diesel.

One general-purpose vehicle which will be shown is the Glover, Webb and Liversidge salvage van mounted on a Bantam 122in. wheelbase. It can be used as a salvage vehicle or a refuse collector in emergencies. It has a 25 cu yd body and a rear-end tipping gear, together with a three-man crew cab.

Making its first public appearance is the Powell Duffryn Engineering Ltd's Packslave II static packer. This new model has an integral power pack but many of the components are interchangeable with Packslave I.

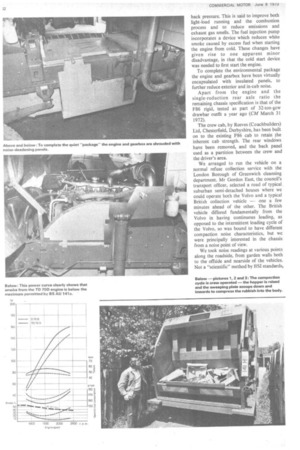

Waste is tipped into the charging box through a 56in. by 42in. top opening. A reciprocating plate then forces it into a container. In each cycle 2.2 cu yd is displaced in 30sec. UNDER environmental pressures, manufacturers are working to produce quieter and cleaner vehicles. One recent product of this enterprise is Volvo's so-called "city" engine, the TD 70D, a derated and "environmentally tuned" version of the 6.7-litre turbocharged diesel used in the Volvo F86 range of commercial vehicles.

One of its urban applications will be within municipal fleets, since these spend much of their working life in built-up areas. CM was recently given the opportunity of putting the first Volvo TD 70D-engined chassis to enter the UK through some operational trials — aimed particularly at seeing just how much quieter it is than previous generations of municipal vehicles.

The test vehicle had a standard Norba intermittent rear-loading refuse collection body (fitted by Arenco-Alite Ltd, of Letchworth, Herts) of familiar design and without any special noise insulation modifications.

The chassis is based on the F86 16ft lin.-wheelbase four-wheel rigid model. The engine has a maximum net output of 160 bhp at 2500 rpm DIN and maximum net torque of 412 lb ft at 1400 rpm DIN and because it is still in its pre-production stage it has yet to be presented for certification to BS AU 141a.

In order to reduce exterior noise and vibration the sump pan has been reinforced, while a change of camshaft has improved engine breathing. A regulator valve in the exhaust manifold restricts the flow of exhaust gases at light engine loads, recirculating them back into the engine to mix with the fresh combustion charge and simulating an additional load by increasing back pressure. This is said to improve both light-load running and the combustion process and to reduce emissions and exhaust gas smells. The fuel injection pump incorporates a device which reduces white smoke caused by excess fuel when starting the engine from cold. These changes have given rise to one apparent minor disadvantage, in that the cold start device was needed to first start the engine.

To complete the environmental package the engine and gearbox have been virtually encapsulated with insulated panels, to further reduce exterior and in-cab noise.

Apart from the engine and the single-reduction rear axle ratio the remaining chassis specification is that of the F86 rigid, tested as part of 32-ton-gcw drawbar outfit a year ago (CM March 31 1972). The crew cab, by Reeves (Coachbuilders) Ltd, Chesterfield, Derbyshire, has been built on to the existing F86 cab to retain the inherent cab strength. The rear windows have been removed, and the back panel used as a partition between the crew and the driver's area.

We arranged to run the vehicle on a normal refuse collection service with the London Borough of Greenwich cleansing department. Mr Gordon East, the council's transport officer, selected a road of typical. suburban semi-detached houses where we could operate both the Volvo and a typical British collection vehicle — one a few minutes ahead of the other. The British vehicle differed fundamentally from the Volvo in having continuous loading, as opposed to the intermittent loading cycle of the Volvo, so was bound to have different compaction noise characteristics, but we were principally interested in the chassis from a noise point of view. We took noise readings at various points along the roadside, from garden walls both io the offside and nearside of the vehicles. Not a "scientific" method by BSI standards, because it was difficult to totally exclude background noise, but sufficient to show the actual noise levels experienced by the people concerned.

The Volvo /Norba had a distinct advantage from an overall noise standpoint, because the intermittent-compaction body was working at roughly 10-minute intervals and otherwise the general exterior noise was that generated by the chassis only (a characteristic of all intermittent loaders), whereas the British vehicle with continuous loading returned consistently higher noise readings.

Typical readings achieved during the operational trial with the noise meter placed directly opposite to the stationary vehicle at a distance of about 12ft, first on one side and then the other, returned readings of 68 'dBA from the Volvo without the loading mechanism in operation. But each time the mechanism operated, peak readings up to 74 dBA were recorded. Readings from the British vehicle were consistently around 76 dBA from each side, 2 dBA greater than the peak recorded from the Norba body and up to 8 dBA noisier than the Volvo chassis-only reading. Also, as a matter of interest, comparable figures obtained with a 1965-registered continuous-loading vehicle in a different area were 89 dBA nearside and 86 dBA offside. This vehicle is about to be replaced, but it suggests that noise levels rise considerably with age. (Decibel readings are logarithmic and a 3 dBA increase represents a doubling of noise level.) Immediately the two newer vehicles had left the area cf our Greenwich trial we interviewed 15 householders, asking if they had observed any differences, and learned that four had noticed that the Volvo was quieter. Although this may seem a small response, my impression is that the refuse collection vehicle is accepted as part of the urban scene, and as such people take little if any notice of it. Consequently, while most of the people we interviewed had recognized visually that one was new, that was the extent of their immediate reaction.

Since the Greenwich trial involved only one other vehicle as a comparison with the Volvo, we decided to run three different British makes of refuse collection vehicle through the British Standards Institution test, plus the Volvo, to discover the more general noise level for current refuse collectors. Manufacturers provided the vehicles, which had three different types of continuous-loading body and the tests were conducted to BSI requirements on a flat, open site at the East and South London Group Training Association at Catford Stadium.

As with the operational trial, the Volvo chassis proved to be the quietest. Using fifth gear and accelerating from three-quarters of the engine speed at which maximum power occurs (as BSI requires) we recorded a maximum exterior noise level of 82 dBA, the same figure being obtained from both sides of the vehicle. The British vehicles without any special quiet-running modifications returned an overall average reading of 87 dBA; a maximum reading of 89 dBA was recorded from one vehicle.

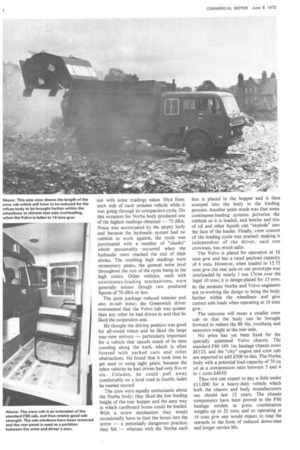

Finally, we conducted our own stationary test with noise readings taken lOyd from each side of each unladen vehicle while it was going through its compaction cycle. On this occasion the Norba body produced one of the highest readings obtained — 75 dBA. Noise was accentuated by the empty body and because the hydraulic system had no rubbish to work against, the cycle was punctuated with a number of "clunks" which presumably occurred when the hydraulic rams reached the end of their stroke. The resulting high readings were momentary peaks, the general noise level throughout the rest of the cycle being in the high sixties. Other vehicles, each with continuous-loading mechanisms, were generally noisier though two produced figures of 70 dBA or less.

The quiet package reduced exterior and also in-cab noise; the Greenwich driver commented that the Volvo cab was quieter than any other he had driven in and that he liked the suspension seat.

He thought the driving position was good for all-round vision and he liked the large rear-view mirrors — particularly important for a vehicle that spends much of its time crawling along the kerb, which is often littered with parked cars and other obstructions. He found that it took time to get used to using eight gears, because the other vehicles he had driven had only five or six. Unladen, he could pull away comfortably on a level road in fourth; laden he needed second.

The crew were equally enthusiastic about the Norba body; they liked the low loading height of the rear hopper and the easy way in which cardboard boxes could be loaded. With a screw mechanism they would occasionally have to feed the boxes into the screw — a potentially dangerous practice, they felt — whereas with the Norba each box is placed in the hopper and is then scooped into the body in the loading process. Another point made was that some continuous-loading systems pulverize the rubbish as it is loaded, and bottles and tins of oil and other liquids can "explode" into the face of the loader. Finally, crew control of the loading cycle was praised; making it independent of the driver, said one crewman, was much safer.

The Volvo is plated for operation at 16 tons gvw and has a rated payload capacity of 6 tons. However, when loaded to 15.75 tons gvw the rear axle on our prototype was overloaded by nearly 1 ton 17cwt over the legal 10 tons; it is design-plated for 13 tons.

At the moment Norba and Volvo engineers are re-working the design to bring the body farther within the wheelbase and give correct axle loads when operating at 16 tons gvw. The outcome will mean a smaller crew cab so that the body can be brought forward to reduce the Bft 6in. overhang and excessive weight at the rear axle.

No price has yet been fixed for the specially quietened Volvo chassis. The standard F86 16ft lin. haulage chassis costs £6123, and the "city" engine and crew cab are expected to add £500 to this. The Norba body with a potential load capacity of '70 Cu yd at a compression ratio between 3 and 4 to 1 costs 14650.

Thus one can expect to pay a little under £11,000 for a heavy-duty vehicle which both the chassis and body manufacturers say should last 12 years. The chassis components have been proved in the F86 haulage models at gross combination weights up to 32 tons, and so operating at 16 tons gvw one would expect to reap the rewards in the form of reduced down-time and longer service life.