High Performancc an Oil-engined Ambulance

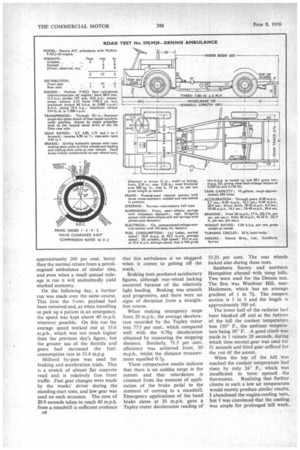

Page 60

Page 61

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

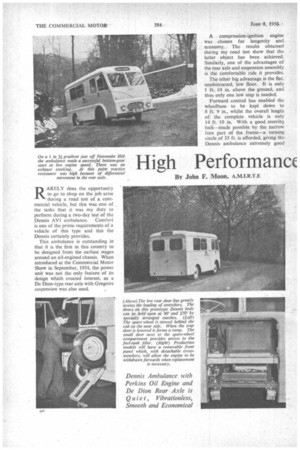

By John F. Moon, A.M.T.R.T.E RARELY does the opportunity to go to sleep on the job arise during a road test of a commercial vehicle, but this was one of the tasks that it was my duty to

perform during a two-day test of the Dennis AV1 ambulance. Comfort is one of the prime requirements of a vehicle of this type and this the Dennis certainly provides.

This ambulance is outstanding in that it is the first in this country to be designed from the earliest stages around an oil-engined chassis. When introduced at the Commercial Motor

Show in September, 1954, the power unit was not the only feature of its design which created interest, as a De Dion-type rear axle with Gregoire suspension was also used. A compression-ignition engine was chosen for longevity and economy. The results obtained during my road test show that the latter object has been achieved. Similarly, one of the advantages of the rear axle and suspension assembly is the comfortable ride it provides.

The other big advantage is the flat, unobstructed, low floor. It is only 1 ft. 10 in. above the ground, and thus only one low step is needed.

Forward control has enabled the wheelbase to be kept down to 8 ft. 9 in., whilst the overall length of the complete vehicle is only 14 ft. 10 in. With a good steering lock—made possible by the narrow fore part of the frame—a turning circle of 35 ft. is afforded, giving the Dennis ambulance extremely good manceuvrability. This is of great 'importance under emergency conditions.

Although a few ambulance departments in this country are using oilengined chassis in limited numbers, there is still prejudice against them. This arises mainly through fear that noise and vibration will disturb critically ill patients, and that acceleration and maximum speed will not be high. None of these remarks can be applied to the Dennis design.

The engine is a Perkins P.4 (C), as used in private cars and taxis. It is appreciably quieter than the P.4 (V) engine, currently fitted in commercial vehicles, mainly because the injection pressure has been reduced from 120 atmospheres to 100 atmospheres.

Its governed speed is 3,000 r.p.m. (as opposed to 2,400 r.p.m.), at which speed it develops 60 b.h.p., and when used with a 4.55 to 1 ratio axle gives a maximum road speed of 58-59 m.p.h. This is fast enough for normal ambulange work in Great Britain.

Engine suspension has been the subject of exhaustive development work by the Dennis engineers, with the result that it would be hard to find better insulation between power unit and chassis. Even when the engine is idling it is difficult to detect the slightest vibration in the driving compartment, and there is certainly none to be felt in the rear of the body.

Good acceleration is afforded by the 134 lb.-ft. torque available at 1,500 r.p.m. and the quick gear change possible through the medium of an efficient synchromesh and a smooth gear-change linkage.

As supplied for test, the chassis was fitted with a Dennis ambulance body, the vehicle having been used over the past few months for demonstration. The body had been designed to give a pleasant appearance with clean lines and comfort able accommodation for either two stretcher cases or one stretcher and five sitting cases, with an attendant seated at the front.

The driving compartment has ample room for a driver and attendant, and, as the engine and radiator are set back from the front of the frame, the driving seat can be reached from both sides of the vehicle. Deep windscreen panels and large windows in and to the rear of the cab doors give the driver a glasshouse view.

Iron weights totalling 5 cwt. had been placed in the rear of the body and with the Dennis driver, myself, test equipment and cans of fuel added, the total imposed load was 10 cwt. This brought the gross weight up to 2 tons 171 cwt., which is the recommended rating. Axle-loading checks on the weighbridge showed the front axle to be carrying 8+ cwt. more than the rear axle.

A fuel consumption run was tackled first. It was conducted over a 13-mile stretch of the Guildford Horsham road, one run being made in each direction. This route is not particularly favourable for consumption tests, as it passes through several villages which demand a reduction in speed. It is hilly and, because it is mainly narrow, traffic' delays may occur, but it was not necessary to use the intermediate gear ratios.

The run was made at a comfortable cruising speed with the speedometer needle near the " 35 " mark for most of the time. The average speed for the complete journey was 32.2 m.p.h. and the consumption rate was 35.9 m.p.g. This figure is approximately 200 per cent. better than the normal return from a petrolengined ambulance of similar size, and even when a small annual mileage is run it will undoubtedly yield marked economy.

On the following day, a further " run was made over the same course. This time the 5-cwt. payload had been removed and, as when travelling to pick up a patient in an emergency, the speed was kept above 40 m.p.h. wherever possible. On this run the average speed worked out at 35.6 m.p.h., which was not much higher than the previous day's figure, but the greater use of the throttle and gears had increased the fuelconsumption rate to 33.4 m.p.g.

Milford by-pass was used for braking and acceleration trials. This is a stretch of almost flat concrete road and is relatively free from traffic. Fast gear changes were made by the works' driver during the standing-start tests, and low gear was used on each occasion. The time of 20.9 seconds taken to reach 40 m.p.h. from a standstill is sufficient evidence D8 that this ambulance is no sluggard when it comes to getting off the mark.

Braking tests produced satisfactory figures, although rear-wheel locking occurred because of the relatively light loading. Braking was smooth and progressive, and there were no signs of deviation from a straightline course.

When making emergency stops from 20 m.p.h., the average deceleration recorded by the Tapley meter was 77.5 per cent.. which compared well with the 0.79g deceleration obtained by measuring the stopping distance. Similarly, 71.5 per cent. efficiency was achieved from 30 m.p.h., whilst the distance measurement equalled 0.7g.

These comparative results indicate that there is no sudden surge in the system and that retardation is constant from the moment of application of the brake pedal to the moment of coming to a standstill. Emergency applications of the hand brake alone at 20 m.p.h. gave a Tapley-meter deceleration reading of 33.25. per cent. The rear wheels locked also during these tests.

Southern Surrey and northern Hampshire abound with steep hills. Two were used for the Dennis test. The first was Woolmer Hill, near Haslemere, which has an average gradient of 1 in 7-i. The steepest section is 1 in 5 and the length is approximately 500 yd.

The lower half of the radiator had been blanked off and at the bottom of the hill the coolant temperature was 130° F., the ambient temperature being 38° F. A good climb was made in 1 minute 20 seconds, during which time second gear was used for 31 seconds and third gear sufficed for the rest of the ascent.

When the top of the hill was reached the coolant temperature had risen by only 24° F., which was insufficient to have opened the thermostat. Realizing that further climbs in such a low air temperature would merely produce similar results, I abandoned the engine-cooling tests, but I was convinced that the cooling was ample for prolonged hill work.

A descent of Woolmer Hill was made in neutral and the foot brake was used to keep the speed down to 20 m.p.h. At the bottom of the hill an emergency foot-brake application was made from this speed and a Tapley-meter reading of 68 per cent. was recorded. This showed a reduction in efficiency of only 3.5 per cent. when compared with the original braking tests, and there was no smell, smoke, fade, or increased pedal travel. The time taken by the descent was 1 minute 25 seconds.

Starting on 1 in 31

The ambulance was then taken to Nutcombe Hill to test engine power and hand-brake efficiency. Halfway up the hill there is a right-hand turn into a side road, which has a steep camber and a maximum gradient of '1 in 31. A smooth start was made from this point in low ratio, despite the increased tractive resistance caused by the differential action.

There was no smoke visible in the exhaust during this test and only part throttle was used. There was no difficulty in preventing the vehicle from running backwards by applying the hand brake.

It was during the return from Nutcombe Hill to the Dennis works at Guildford that I travelled in the back of the ambulance, lying on the left-hand stretcher bed. The warmth from the efficient body heater, the almost complete absence of noise and the extremely smooth, sway-free suspension contributed towards the restfulness of the position and within a short time I was fast asleep.

Easy to Drive

Several times during the test I drove the ambulance and found it to be one of the easiest vehicles that it has ever been my duty to handle. The controls were light and well placed, gear changing being particularly easy and smooth, and the all-round visibility could hardly be bettered.

Maintenance tasks were carried out in the dispatch shop at the Dennis works. All the greasingwith the exception of the rear hubs—was done from a pit and the 21 points were attended to in 5 minutes. Rubber bushes in the spring and shackle eyes eliminate the need for attention at these points.

While in the pit, the rear-axle oil level was checked in 1 minute 20 seconds. There is a combined filler and level plug in the rear casing of the differential housing and, as there was no trap in the floor of the body, it was impossible to reach this other than by using a pit. Returning to ground level, I changed the near-side, rear wheel in 9 minutes. This task was greatly simplified by the Smith's Jackall built-in jacking system, the control for which is located under the front floorboards of the cab. A selector valve in the system enables either the rear or front wheels to be jacked up separately or simultaneously.

The spare wheel is housed behind the main bulkhead and was reached through a large trap in the near side of the body. When this trap is lowered it forms a convenient ramp for the removal or replacement of the wheel. The wheel itself is retained by a detachable screw clamp.

The built-in jacks were used also for brake adjustments and the total time taken for this job was 31 minutes. This was divided into 50 seconds for jacking up all four wheels, 1 minute 15 seconds for adjusting the front brakes, 50 seconds for adjusting the rear brakes and 20 seconds for releasing the jacks. With the help of a works fitter, the braking system was bled in

10 minutes.

Bonnet Quickly Removed

Raising the near-side bonnet section took 13 seconds, whilst the off-side portion, which is secured by four Dzus fasteners, was detached in 8 seconds. With these covers removed it was possible to check the water level in 12 seconds and the engine oil level in 30 seconds.

I then removed No. 1 injector in 1 minute 6 seconds and replaced it in 1 minute 33 seconds. As all the injectors are equally well placed for maintenance there was no point in attending to all four, and the job was done while standing at the cab door.

The air-cleaner cover was removed in 1 minute 20 seconds in order to check the oil level, and replacement occupied a further 1 minute 10 seconds. The task is prolonged by the need first to detach the air channel between the inlet manifold and the cleaner itself.

Tappet adjustments occupied 16 minutes. One fitter sat in the mate's seat and checked and adjusted the clearances while another assistant turned the engine over from below. There is no provision for the use of a starting-handle from the front of the vehicle.

Fluid Level Checked The level in the Girling brake reservoir was checked in 11 minutes. The reservoir is beneath the radiator air duct and is reached by swinging back a trap in the tread plates. The, reservoir for the Jackall system is below the near-side windscreen panel andthe level of the fluid in it was tested in 7 seconds. The last levelcheck concerned the gearbox, on which 3 minutes was spent.

The dipstick is fitted in the box and a hinged trap provided in the rear of the engine cowl, but this is prevented from being opened by the position of the spare wheel, which has first to be removed. In future designs the shape of the trap is to be modified to avoid this necessity. Access to the trap is gained by removing a panel in the front bulkhead of the body.