THE USE OF INGENUITY.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Practical Experiences Recounted by Our Driver and Mechanic Readers.

WITHDRAWING ball races from rear-axle sleeves is sometiAs difficult without a special puller, but "WI?.," of Alloa, suggests a design which can be made at home.

. First take a mild-steel collar, about a in. thick, and turn it to a driving lit in the bore of the ball race to be handled. Next . bore a tapered hole .through the collar—a 30-degree taper will do. A tapered -ping is next made to fit the collar and one end of this plug is welded to a -1-in, bar, the end opposite to the taper being screwed. This bar should be long enough to reach right through the axle sleeve. The collar is finally split on one side by means of a hacksaw and is slightly ex

panded with a cold chisel. • In operation the collar is driven • through the ball race, the large end of the taper being farthest from the direction of the pull. The 1-in, bar is then introduced through the sleeve and collar, a washer is slipped over its end and a nut run dawn the thread. The tapered plug is pulled bard up against the collar as the nut is turned, thus expanding the collar and 'pulling the ball race with it. The greater the pull the greater the pressure on the inner nee.

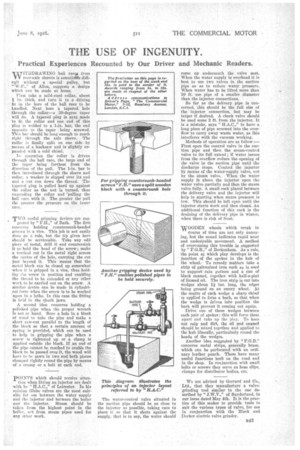

TWO useful gripping devices are sug

gested by " of Bath. The first concerns holding countersunk-headed screws in a vice. This job is not easily done as a rule, but the tip given here should be serviceable. Take any odd piece of metal, drill it and countersink it to 'hold the head of the screw; make a vertical cut in the metal right across the centre of the hole, carrying the cut just beyond it. This means that the metal block Can be closed up somewhat when it is gripped in a vice, thus holding the screw in position and enabling the thread to be extended or any other work to be carried out on the. screw. A similar device can be made in cylindrical form when the screw is to be worked upon in a lathe. In this case the fitting is held in the c_huek jaws.

A second idea concerns holding a polished pipe when the proper wrench ts not at hand. Bore a hole in a block of wood to take the pipe and make a short saw-cut parallel to the length of the block so that a certain amount of spring is provided, which can be used to help in gripping the pipe when a screw is tightened up or a clamp is applied outside the block. If an end of the pipe cannot be reached to enable the block to be passed over it, the wood will have to he sawn in two and both pieces clamped tightly round the pipe by means of a cramp or a. bolt at each end.

• poucTs which should receive tittention when fitting an injector are dealt with by " H.A.C.," of Leicester. in his opinion Globe valves are the most suitable for use between the water supply and the injector and between the boiler and the injector. Steam should be taken from the highest point in the boiler, net from steam pipes used for any other work.

The water-control valve situated in the suction pipe should be as close to the injector as possible, taking care to placeit so that it shuts against the supply, that is to saY, the water should Came• up underneath the valve seat. When the water supply is overhead it is best to use two valves in the suction pipe so as to reduce water pressure., When water has to be lifted more than 10 ft. use pipe of a smaller diameter than the injector connections.

So far as the delivery, pipe is. concerned, this should be the full size of the injector connection, but may be larger if desired. A check valve should be used some 2 ft. from the injector. It is a mistake, says " H.A.C.," to have a long piece of pipe screwed into the overflow"to carry away waste water, as this interferes with the vacuum working.

Methods of operation are as follow:— First open the control valve in the suction pipe and then the steam-control valve to its full extent ; if water issues from the overflow reduce the opening of the valve in the suction pipe until the discharge stops. Control the injector bY means of the water-supply valve, not by the steam valve. When the water supply is above the injector open the water valve partially and then the steam valve fully. A small cock placed between the delivery valve and the injector will help in starting when steam pressure is low. This should be left open until the injector starts work and then closed. An additional function of this cock is the draining of the delivery pipe in winter, when there is risk of frost.

WOODEN wheels which creak in course of time are net only annoying, but the sound indicates rapid wear and undesirable movement. A method of overcoming this trouble is suggested by " F.G.B.," of Beckenham. As a rule, the point at which play develops is the junction of the spokes in the hub of the wheel.To remedy matters take a strip of galVanized iron such as is used to supportrain gutters and a can of Mack enamel, together with half-a-pint of linseed oil. The iron strip is cut into wedges about n ins, long, the edges being ground on an emery wheel. At the centre of each wedge a sharp chisel is applied to form a barb, so that when the wedge is driven into position the barb will prevent it coming out again. Drive one of these wedges between each pair of spokes; this will force them apart and take up the play. To keen out rain and dirt, the oil and :enamel should be mixed together and applied to the hub liberally, particularly round the heads of the wedges.

Another idea suggested by " F.O.B." concerns metal strips, generally, brass, which can be perforated with an ordinary leather punch. These have many useful functions both on the road and in the shop. In conjunction with small bolts or screws they serve as hose clips, chimps for distributor bodies, etc.

We are advised by Gerrard and Co., Ltd., that they manufacture a valvegrinding tool similar to the one described by " J.W.V.," of Sunderland, in our issue dated May 4th. It is the practice of this maker to provide tools to suit the various types of valve, for use in conjunction with the Black and Decker electric valve grinder.