Contributions from Drivers and Mechanics.

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY for the Best Communication Received, and One Penny a Line of ten words for any thing else published.

Drivers of commercial-motor vehic es and tractors, and mechanics and foremen of garages or shops, are invited to send short co rtributions on any subject which is likely to prove of interest to oar readers. Workshop tips and smart repairs ; long and successful runs ; interesting photographs : all are suitable subiects. Send a post-card, or a letter, or a sketch to us—no matter how short, Or how wriden,or how worded. We will knock it into shape" and prepare sketches, where necessary, before publication. The absence of a sketch des not disqualify for a prize. Wizen writing use one side of the paper only and men ion your employer's name as a guarantee of bona fides. Neither your own nor your employer's name will be disclosed. Payment will be made imme. diatelv after publication. Address your letters to The Editor, THE COMMERCIAL MOTOR, 7-15. Rosebery Avenue., London. E.C.

That Exhaust Whistle.

[884] " W.W.H." (Devon) writes :—" I shall be glad if you can find room in the columns of your paper for me to answer letter No. 876 from 'J.K.' (Cornwall), in which he criticised my letter No. 862. You may remember that this dealt with an exhaust whistle. Your correspondent says that he was almost sure that I got the idea from another depot. I should like to state, in answer to his letter, that I have never even seen an exhaust whistle made out of an old oil cap before I made mine. If J. K.' can prove otherwise, I will gladly forfeit my 10s. prize, also 10s. on the top of it to him. I can only say that it is a great pity that J. K.' did not see fit to send his own invention to THE COMMERCIAL MOTOR. Probably, then, he might not be in such a hurry to accuse others of using his ideas. I quite agree with him that the whistle cannot be worked when the engine is stopped. Perhaps J.K.' can tell us the reason why."

The Repair and Refitting of Valves for Petrol Engines.

The sender of the following communication has been awarded the 10s. prize this week.

[885] " A.C." (Peckham) writes :—" My present letter largely deals with the repair and maintenance of internal-combustion-engine valves, and I believe that a short article on this subject, from the point of view of the man who has to repair and to adjust petrol engines, will be of considerable interest to your readers. " Many an engine cannot be made to run satisfacfa.c.torily or to pick up at an well, because of wear that has taken place on the valve stems or in the guides. This condition allows additional air to be sucked up where it is not wanted and so, as a rule, causes derangement of the mixture. If new valves and guides can readily be bought, it is then quite a simple matter to put things in order ; but if, for example, the expense of such replacing is a serious consideration, or if the guides have to be east in one with the cylinders, other means must be adopted. When new valves alone will not cure the trouble, other valves stouter in the stem must be procured and the guides must be made to suit. Such a job, however, is rather a handful, and many men would therefore be inclined to put off the evil day when it must be done. There is, however, no particular difficulty about it, if the workman goet about the thing in the proper way.

" Fir.t of all the valve guides must be reamered out true, and this is best done with a fluted reamer. If one. of these is not handy. however, a ' D ' bit will do quite as well. If the valve guides are cast in one with the cylinders, then the whole casting must be bolted down on to the table of the drilling machine, so that the cutter can be put through the guide in position. It is as well, as I have found, when this method is being employed, to use a simple form of universal joint between the cutter and the spindle, in order to ensure that the cutter shall run true.

This can easily be made from a plain piece of mild steel and a short length of tube. The mild-steel end must be of a suitable size to go in the chuck, and the three parts should be joined by split pins with what is known as a sloppy fit.'

" A valve cutter should be made to recut the valve seat, and this, I have found, can be made very conveniently as I have shown in the sketch [All the sketches in this letter have been redrawn by us.— ED.]. The cutter spindle should be made out of good mild-steel, whilst the cutter itself can be either Ubas

or good ease-hardened mild steel ; the teeth need not be spaded equally, but I have found that on the average size cutter from le to 23 teeth give the cleanest cut. The cutter is revolved by a tap wrench which fits on the square at the end of the spindle. If it is found that sufficient pressure cannot be put on by hand, the bottom of the cutter stem can be screwed to take a nut. A flat surface should be filed on to the screwed p,ortion so that a ' washer may he fitted. The cutter should he made considerably larger than the valve seat, so as to remove the well which develops with wear. If the cutter be too large to be inserted through the valve cap it can be pushed up through the cylinder—assuming of course that the cylinders are removed from the engine case, and it can then be dropped on to the valve seat. The stem may then easily be inserted and tightened up by a bent pin or spanner, the business ends of which fit two drilled holes in the cutter head.

"Let us suppose now that new valves are required; these can be turned from stampings in the usual way, or sometimes old valves of a larger size can be found. These, as a rule, are better than new ones, as it may be fairly well assumed that there is little danger of their having hidden flaws. If old ones be used, there is, as a rule, but little metal to be removed from the stems. They must be centred quite true for turning, and if no steady rest be at hand, one should be made out of a piece of 5-16-in. plate, which should be drilled to take three brass screws. The steady-rest should be held in the sliderest, and the valve should be chucked true by the projection on the head. The valve may then be centred with a square centre in the usual way.

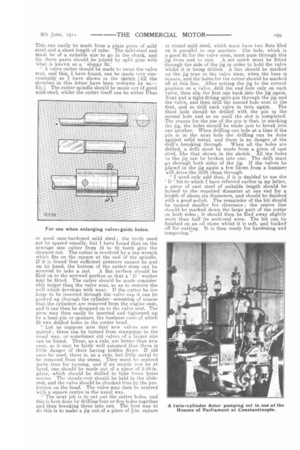

" The next job is to Ind out the cotter holes, and this is best done by drilling four or five holes together and then breaking these into one., The hest way to do this is to make a jig out of a piece of fin. square

or round mild steel, which must have two flats filed on it parallel to one another. The hole, which is a good fit for the valve stem, must pass through this jig from end to end. A set screw must be fitted through the side of the jig in order to hold the valve whilst it is being drilled. A line should be marked on the jig true to the valve stem, when the base is square, and the holes for the cotter should be marked oft at this line. After setting the jig to the correct position on a valve, drill the end hole only on each valve, then slip the first one back into the jig again. Next put a tight-fitting split-pin through the jig and the valve, and then drill the second hole next to the first, and so drill each valve in turn again. The third hole should be drilled with the pin in the second hole and so on until the slot is completed. The reason for the use of the pin is that, in marking the jig, the holes should be made just to break into one another. When drilling one hole at a time if the pin is in the next hole the drilling can be done against solid metal, and there is no danger of the drill's breaking through. When all the holes are drilled, a, drift must be made from a piece of cast steel, like that shown in the sketch. All the holes in the jig can be broken into one. The drift must go through both sides of the jig. If the valves be placed in the jig again a few blows from a hammer will drive the drift clean through.

" I need only add that, if it is decided to use the I) ' hit to which I have referred earlier in my letter, a piece of east steel of suitable length should be turned to the required diameter at one end for a length of about six diameters, and should be finished with a good polish. The remainder of the bit should be turned smaller for clearance ; the centre line should be marked down the large part of the cotter on both sides ; it should then be filed away slightly more than half its sectiqnal area. The bit can be finished on an oil stone whilst it is soft, and backed off for cutting. It is then ready for hardening and tempering!'