ENGINE AND RADIATOR REPAIRS.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Some Useful Tips from Our Driver and Mechanic Readers.

TT IS quite likely that a number ot _Lour readers are acquainted with Simplex petrol locomotives. At any rate it will be sufficient for our purpose if they realize that these machines are similar to commercial motor vehicles, in that they burn petrol as fuel and have four-cylinder engines and radiators of the usual type. An ititeresting letter which we have from " G.W.," of Masham, concerns a difficulty which arose in connection with several of a fleet of these locomotives, for the care of which he was responsible. Overheating developed, becoming gradually worse until it was the rule for the circulating water to boil. Upon removing the radiator heads, it was found that quite a large number of the tubes were choked by a deposit of lime from the water which had to be used. At first it seemed as though it was going to be impossible to clean them, for any endeavour to persuade a wire to penetrate the deposit only resulted in the material being packed more tightly than before.

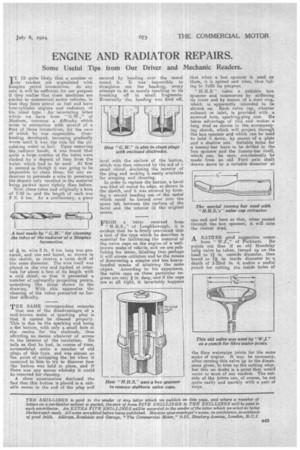

Now, these tubes had originally a bore of 7-32 in. and the length of each was 2 ft. 6 ins. As a preliminary, a, piece

of las in. wire 2 ft. 9 ins, long was procured, and one end bored, as shown in the sketch, to receive a twist drill of the same diameter. 'Che wire itself was placed in the vice and hacked at intervals for about a foot of its length with a cold chisel, so that it presented a number of outwardly projecting points, something like those shown in the drawing. With this apparatus the cleaning of the tubes presented no further difficulty.

THE SAME correspondent remarks that one of the disadvantages of a well-known make of sparking plug is that it cannot be cleaned properly. This is due to the sparking end being a flat button, with only a small hole in the centre for the electrode, thus affcrding no means whatever of access to the interior of the insulation. He tells us that he had, in course of time, accumulated quite a number of old plugs of this type, and was almost on the point of scrapping the lot when it occurred to him to try to discover how the button was held in place, and if there was any means whereby it could be removed for cleaning.

A close examination disclosed the fact that this button is placed in a suitable recess in the end of the plug and

secured by beading over the metal round it. It was impossible to straighten out the beading, every attempt to do so merely resulting in its breaking off in. small fragments. Eventually the beadiil was filed off, level with the surface of the button, which was then removed by the aid of z small chisel, disclosing the interior of the plug and making it, easily available for scraping and cleaning. In order to replace the button, a bevel was filed all round its edge, as shown in the sketch, and it was secured by forming a second beading out of the metal which could be turned over into the space left between the surface of the bevel and the interior of the original recess.

FROM a letter received from " H.H.S.," of Loughborough, it is evident that he is firmly convinced that a tool of the type which he describes is essential for facilitating the removal of the valve caps on the engine of a wellknown make of vehicle, and we are publishing his letter, thinking that perhaps it will arouse criticism and be the means of discovering a simpler and less heavyhanded means of attaining the same object. According to his experience, the valve caps on these particular engines are only in. deep, and if the caps are at all tight, it invariably happens

that when a box spanner is used on them, it is spread and rises, thus failing to fulfil its purpose.

" H.H.S." takes a suitable box spanner and commences by stiffening its lower end by means of a steel ring, which is apparently intended to be shrunk on. Each valve cap, whether exhaust or inlet, is provided with a sciewed hole, sparking-plug size. He takes advantage of this and makes a long stud as shown in the accompanying sketch, which will project through the box spanner and which can be used to hold it. down, by means of a plate and a shallow nut. Suitable holes for a tommy-bar have to be drilled in the box spanner and the tommy-bar itself, which can, he says, conveniently be made front an old Ford axle shaft drawn down to a suitable diameter at

one end and bent so that, when passed through the box spanner, it will miss the central stud.

A RATHER good suggestion comes

from " W.J,," of Peckham. He points out that if an old Maudsiay tulip valve be taken, turned up on the head to 11 in. outside diameter, then bored to Ili in, inside diameter to a depth of 3-32nd in. it makes a useful punch for cutting the inside holes of the fibre waterpipe joints for the same make of engine. It may be necessary, after turning this valve up to the dimensions given, to trim up the cutting edge, but this no doubt is a point that would occur to most of our readers. The outside of the joints can, of course, be cut quite easily and quickly with a pair of snips.