For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

Lamps Alight.

On Saturday, July 12th, light your lamps at 9.42 in London, 10.54 in Edinburgh, 10.11 in Newcastle, 10.7 in Liverpool, 9.56 in Birmingham, 9.52 in Bristol, and 10.55 in Dublin.

Re-threading Forged Rear Axle Ends.

The sender of the following emnInunication has been awarded the 10s. prize this week.

[1992] " F.N." (Guildford) writes :—" Everybody who has had any experience of the behaviour of subsidy type vehicles overseas will be aware of the frequency with which the thread on the end of solid forged double-banjo type rear axles have to be repaired. They were usually too fine and rapidly wore.

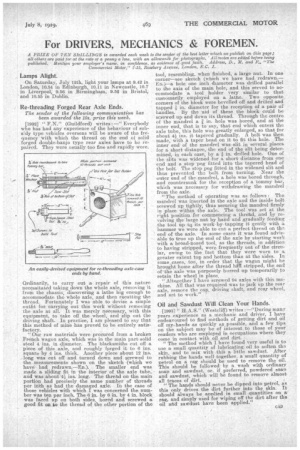

Ordinarily, to carry out a repair of this nature necessitated taking down the whole axle, removing it from the chassis, discovering a lathe big enough to accommodate the whole axle, and then recutting the thread. Fortunately I was able to devise a. simple outfit for carrying out this work without removing the axle at all. It was merely necessary, with this equipment, to take off the wheel, and slip out the driving shaft. In practice, I am pleased to say that this method of mine has proverd to be entirely satisfactory.

"Our raw materials were procured from a broken French wagon axle, which was in the Main part solid steel 4 ins, in diameter. The blacksmiths cut off a piece •of this axle, and roughly forged it to 6 ins. square by 4 ins. thick. Another piece about 12 ins. -long was cut off and turned down and screwed to the measure-ments shown on the sketch (which we have had redrawn.—En.). The smaller end was made a sliding fit in the interior of the axle tube, and was about 4:1 ins. long. The thread on the me,in portion had precisely the same nurnber of threads per inch as had the damaged axle. In the case of those vehicles with which I was concerted the number was ten per inch. The.6 in. by 6 in. by 4 in. block was faced up on both sides, bored and screwed a good fit on. to the thread of the other portion of the tool, resembling, when finished, a large nut. In one corner—see sketch (which we have had redrawn. ED.)—a hole one inch diameter was drilled parallel to the axis of the main hole, and this served to accommodate a tool holder very similar to that• customarily employed on a lathe. Two opposite corners of the block were bevelled off and drilled and tapped in, diameter for the reception of a pair of handles. By the aid of these the block could be screwed up and down its thread. Through the centre of the mandrel a in. hole was bored, and at the inner end, that is to say, that end which enters the axle tulle, this hole was greatly enlarged, so that for about 4 ins, it tapered gradually. A bolt was then made, with ,a taper head on it to fit this hole. The inner end of the mandrel was slit in several places for a short distance, the end of the slit being determined, in each case, by a in, drilled hole. One of the slits was widened for a short distance from one end and a stop peg fitted into the tapered head of the bolt. The stop peg fitted in the widened slit and thus prevented the bolt from turning. Near the outer end of the.mandrel, a, hole was bored through, and countersunk for the reception of a tomrny bar, which was necessary for withdrawing the mandrel from the axle.

"The method of operating was as follows : The mandrel was inserted in the axle and the inside bolt screwed up tightly, thus securing the mandrel firmly in place within the axle. The tool was set at the right position for commencing a threid, and by revolving the large nut by hand and gradually feeding the tool up ta its work by tapping it gently with a, hammer we were able to cut a perfect thread on the end of the axle. In some eases it was found advisable to true up the end of the axle by starting work with a broad-nosed tool, as the threads, in addition to having stripped, were frequently out of the circular, owing •to the fact that they were worn to a greater extent top and bottom than at the sides. In some cases, too, in order that the wagon might be brought home after the thread IAA stripped, the end of•the axle was purposely burred up temporarily to retain the wheel in place,

"Altogether I have screwed 94 axles with this machine. All that was required was to jack hp the rear axle, remove the cap, (Hying shaft, and rear wheel, and set to work."

Oil and Sawdust Will Clean Your Hands.

[1993] " A.S." (Westeliff) writes : —"During many years experience as a mechanic and driver, I have endeavoured to find methods of getting dirt and oil off myehands as quickly as possible, and a few tips on the subject may be of interest to those of your readers who are employed in occupations where they come in contact with oil and dirt.

"The method which I have found very useful is to use a small quantity of lubricating oil to soften the skin, and to mix with thi's a little sawdust. After rubbing the hands well together. a small quantity of petrol on a rag should be used to remove the oil. This should be followed by a wash with ordinary soar, and sawdust, or. if preferred, powdered soap and sawdust, which will be found to remo,ve almost all traces of dirt.

"The hands should never be dipped into petrol, as this only drives the dirt further into the skin. It should always be applied in small quantities on a rag, and simply used for wiping off the dirt after the oil and sawdust have been applied."