NEW X-TON MODEL IN 16 VERSIONS

Page 76

Page 77

Page 78

Page 79

Page 80

If you've noticed an error in this article please click here to report it so we can fix it.

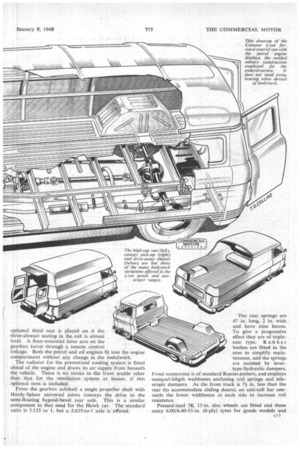

ALTHOUGH a late entrant for the 15-cwt. forwardcontrol van stakes, the range of 1-ton models announced today by Commer Cars, Ltd., has many features which should ensure success. They are the first British contenders in this class to be offered with petrol or oil engines as standard. The petrol engine is the four-cylindered 1.494-litre o.h.v. unit similar to that fitted in current Hillman cars, and identical to the one used in the Commer Express delivery van, The Perkins Four 99 1.621-litre oil engine is the option, available at an extra cost of £112. It produces 40.5 b.h.p. (net) at 3,600 r.p.m. against the petrol engine's 49 b.h.p. (net) at 4,500 r.p.m. '

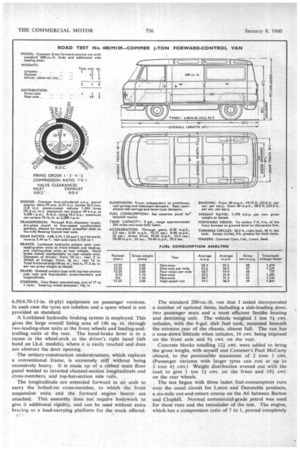

I carried out a road test of a petrol-engined van from the range, and found that it possessed a lively performance' combined with a fuel consumption rate of 28.4 m.p.g. at an average speed of 29.2 m.p,h. The van was running at its maximum permitted gross weight of 2 tons 1 cwt.,

which allowed a -151-cwt. load including the driver and passenger.

Through an impressive arrangement with four bodybuilders and their own associates Rootes, Ltd., Maidstone, Commer offer 16 bodywork variations on the basic model, which can also be supplied in chassis-only and chassis-andcab form. Goods models available include a pick-up, bottle float, gown van, drop-sider, baker's van (in light alloy and plastics with standard internal racking), and high-top van. Passenger versions comprise a light bus, contractor's bus and a model built to public-service-vehicle requirements. There are also a station wagon (on which purchase tax is payable), two and four-berth caravans, ambulance and mobile shop.

Hinged or Sliding Doors

The standard all-steel van body, which provides 200 Cu. ft. of loading space, is offered with hinged or sliding cab doors, and the option of a side-loading door on hingeddoor versions only. The double rear doors fitted have positive, hand-operated retainers and incorporate large windows. A hinged-door 4-ton van was the subject of my road test.

An 8-in.-diameter clutch with hydraulic actuation is used with both engines, and the four-speed gearbox (which is shared with the Express) is unaltered for both applications. It has synchromesh on second, third and top gears, and is mounted in unit with the engine.

The front of the engine-gearbox unit is approximately level with the leading edge of the cab seats, and is mounted on the cross-member carrying the independent front suspension units through a V-shaped rubber sandwich. At the rear the unit is suspended on rubber cone mountings attached to a bracket outrigged from the tailshaft of the gearbox.

The cowl covering the engine is low, so that when an b.12 optional third seat is placed on it the three-abreast seating in the cab is almost level. A floor-mounted lever acts on the gearbox turret through a remote control linkage. Both the petrol and oil engines fit into the engine compartment without any change in the metalwork.

The radiator for the pressurized cooling system is fitted ahead of the engine and draws its air supply from beneath the vehicle. There is no intake in the 'front scuttle other than that for the ventilation system or heater, if this optional item is included. • From the gearbox tailshaft a single propeller shaft with Hardy-Spicer universal joints Conveys the drive to the semi-floating hypoid-bevel rear axle. This is a similar component to that used for the Hawk car. The standard ratio is 5.125 to 1. but a.5.625-to-1 axle is offered.

The rear springs are 47 in. long, 2 in. wide and have nine leaves. To give a progressive effect they are of triplerate type. Rubber bushes are fitted in the eyes to simplify maintenance, and the springs are assisted by levertype hydraulic dampers. Front suspension is of standard Rootes pattern, and employs unequal-lehgth wishbones enclosing coil springs and telescopic dampers. As the front track is 71 in. less than the rear (to accommodate sliding doors), an anti-roll bar connects the lower wishbones at each side to increase roll resistance.

Pressed-steel 5K 15-in, disc wheels are fitted and these carry 6.00/6.40-15-in. (6-ply) tyres for goods models and E!3 6.50/6.7045-in. (6-ply) equipment on passenger versions. In each case the tyres are tubeless and a spare wheel is not provided as standard.

A Lockheed hydraulic braking system is employed. This gives the large overall lining area of 146 sq. in. through two-leading-shoe units at the front wheels and leading-andtrailing units at the rear. The hand-brake lever is in a recess in the wheel-arch at the driver's right hand (left hand on 1.h.d. models), where it is easily reached and does not obstruct the door opening.

The unitary-construction understructure, which replaces a conventional frame, is extremely stiff without being excessively heavy. It is made up of a ribbed main floor panel welded to inverted channel-section longitudinals and cross-members, and top-hat-section side rails.

The longitudinals are extended forward in an arch to carry the bolted-on cross-member, to which the front suspension units and the forward engine bearer are attached. This assembly does not require bodywork to give it additional rigidity, and can be used without extra bracing as a load-carrying platform for the truck offered. The standard 200-cu.-ft. van that I tested incorporated a number of optional items, including a side-loading door, two passenger seats and a most efficient Smiths heating and demisting unit. The vehicle weighed 1 ton 5+ cwt. unladen, with the 9-gal. slab fuel tank, mounted beneath the extreme rear of the chassis, almost full. The van has a nose-down attitude when unladen, 16 cwt. being imposed on the front axle and 9+ cwt. on the rear.

Concrete blocks totalling 12+ cwt. were added to bring the gross weight, with myself and Commer's Paul McCarty aboard, to the permissible maximum of 2 tons 1 cwt. (Passenger variants with larger tyres can run at up to 2 tons 41 cwt.) Weight distribution evened out with the load to give 1 ton 1-1,cwt. on •the front and 19+ cwt. on the rear wheels.

The test began with three laden fuel-consumption runs over the usual circuit for Luton and Dunstable products, a six-mile out-and-return course on the A6 between Barton and Clophill. Normal commercial-grade petrol was used for these runs and the remainder of the test. The engine, which has a compression ratio of 7 to 1, proved completely tractable on this fuel, and " pinking " was noticed on only one occasion during the 200 or more miles covered—a sign of good combustion-chamber design.

During the non-stop run, the vehicle was driven at 33-35 m.p.h. to return an average speed of 29.2 m.p.h. and a fuel-consumption rate of 28.4 m.p.g. Five stops during the six-mile circuit increased consumption to 23.2 m.p.g., whilst 23 stops raised it to 18.7 m.p.g. Following usual practice, the engine was idled for 15 seconds at each halt.

The test vehicle had the standard 5.125-to-1 ratio rear axle which permitted it to be started in second gear on the level, and was later found to give adequate top-gear flexibility and excellent gradient ability. Because of this, I cannot think of many occasions when the optional 5.625to-1 axle would be desirable, provided that the vehicle was not overloaded.

Two further non-stop runs were made over the test course on the following day. With half the load removed, the first was completed at an average speed of 31 m.p.h., and the fuel-consumption rate was 29.5 m.p.g. Unladen, consumption improved by 1.2 m.p.g. and the speed increased by 0.3 m.p.h. The difference between the fully laden and unladen non-stop runs was only 2.3 m.p.g., with an improvement of 2.1 m.p.h. in the average speed. This is probably an indication of good gearing.

With a vehicle capable of over 60 m.p.h. and the M1 so close, I decided to carry out a near-full-throttle laden fun on the motorway. For this test the graduated fuel tank was dispensed with and the consumption was assessed by filling up the main tank at the beginning of the run, and refilling it with a measured quantity of fuel at the end. Starting from Commer's Luton factory, the motorway was joined at the A505 junction, three miles and 71 min. later. I drove north for 28 miles, turned round at the A508 flyover without stopping, and returned to Luton.

Total mileage, including six miles driving to and from the new road, was 62. The run occupied 1 hour 19 minutes, giving an average speed of 46.96 m.p.h. at the surprisingly low consumption rate of 19.1 m.p.g. The 56 miles of motorway were covered at an average speed of 52.4 m.p.h.

Motorway Speed

The van has a maximum speed of about 64 m.p.h. but was cruised at just below 60 m.p.h. most of the time Speed did not drop below 50 m.p.h. on the motorway. It is interesting to note that the time-load-mileage factor of 1,831 is higher than that achieved on the slower six-mile laden run.

Excellent synchromesh on second, third and top gears is provided by the gearbox. Fast gear-changing is hampered slightly by the remote-control linkage between the gearbox turret and the floor-mounted lever. This is not as precise as it might be, but is still a fairly good example of this type of mechanism. That it does work quite well was proved by the standing-start acceleration figures. Starting in first gear, 20 m.p.h. was reached in 5.5 seconds, 30 m.p.h. in 10.75 seconds and 40 m.p.h. in 22 seconds. Each figure is the mean of runs in both directions to eliminate wind and gradient effects.

It took me a little time to get used to the accelerator and the hydraulically actuated clutch. Both have a rather long travel before they become effective. In the case of the accelerator, this obviously results from the roundthe-houses linkage which has to be employed because the carburetter is mounted on the side of the engine opposite to the pedal. The clutch, which otherwise provided a smooth take-up, could, 1 think, be adjusted to provide earlier engagement.

Direct-drive acceleration proved to be smooth, and the vehicle would proceed on the level at about 8 m.p.h. in top gear, accelerating from this speed steadily without pre detonation from the engine or transmission judder.

With 71.2 sq. in. of brake lining for each ton of gross weight, the Commer should possess exceptional braking performance. Although the braking figures recorded were quite satisfactory, the manner in which they were achieved left something to be desired. Stops from both 20 m.p.h. and 30 m.p.h. on an almost dry road resulted in the back wheels lifting because of transference of weight to the front wheels.

As the vehicle was already front-heavy when static, the powerful• two-leading-shoe front brakes, which appeared to take full effect after those on the rear wheels, caused the front of the vehicle to dip some 7 in. under maximum deceleration. Although the rear wheels marked the road, the actual braking effect obtained from them must have been slight. A pressure-limiting device for the frontwheel cylinders might reduce this dipping but impair the braking performance. Although the rear wheels were completely clear of the ground for an instant during two of the stops, the van pulled up in a straight line without steering correction at all times. •

Longer Lever

The hand brake is well positioned below the driver's right hand and gave an average Tapley-meter reading of 33 per cent. when applied from 20. m.p.h. Although this figure is satisfactory, it could be improved if the lever itself were longer to allow better purchase to be obtained.

Hill-climbing, tests took place on the fmile-long Bison Hill, near Whipsnade, which has an average gradient of 1 in 12. The ambient temperature was 48°F. and the coolant temperature before the climb was 172° F. A fast ascent was made in 2 minutes 40 seconds with 45 seconds Id second gear and 13.5 seconds in the lowest ratio: The water temperature, when checked at the top of the hill, was found to have risen by only 60. F., indicating the adequacy of the cooling arrangements.

I turned the van round and drove it down the hill out of gear, using the foot brake to keep' the speed at 20 m.p.h. Top gear was engaged towards the bottom and full throttle applied against the brake to maintain the same speed on the decreasing gradient. This occupied 45 seconds, and the total time for the descent was 2 minutes 29 seconds. A full-pressure brake application from 20 m.p.h. following this pulled the vehicle up in a straightline on the extremely wet road, and gave a reading on the Tapley meter of 83 per cent As it was raining heavily at the time, this was inconclusive as a fade test because water cooled the brake drums. In fact, the meter reading was only 2 per cent. different from that recorded earlier from the same speed under good conditions. However, the Tapley readings were of doubtful value because of the forward pitching during braking. Even though definite conclusions cannot be made from this test, I feel sure that the Commer, with its large area of moulded lining, would not be prone to any great degree of fade.

As it had surmounted the 1-in-61 section of Bison Hill with ease, I took the vehicle to White Hill, Bovingdon, to get a true assessment of the maximum gradient on which it would restart. On the I-in-41 incline it got away with some clutch slip in first gear and would have restarted, facing downwards, in the lower reverse ratio, although I did not try this. The hand brake held easily on this slope.

The suspension gave a comfortable ride under normal conditions. Some roll could be induced by really fast cornering, and this was accompanied by a good deal of noise from the tyres, and a tendency to run wide which could be corrected by opening the throttle. At lower speeds, the anti-roll bar connecting the independent front suspension units effectively checked this tendency. The triple-rate rear springs worked well and gave a good ride even when the vehicle was unladen.

Although the front-axle loading was high, the steering did not become heavy at low speeds. -There was some lost motion in the cam-and-peg gear, but this did not hamper accurate steering, even when a fairly strong cross-wind was encountered on the motorway at speed. I liked the driving position provided by the adjustable bucket seat mounted on the wheel-arch. It has an unusual adjustment mechanism which gives three fore-and-aft positions and alters the height of the seat base slightly at the same time.

The driver's seat, like that for the passenger, tips forward to give access to the engine compartment. The pedals are well positioned, but rubbers are not fitted to them as standard equipment although offered as options. As the metal pedal plates are grooved only vertically, I found that my feet tended to slip forward on them; not a dangerous fault but an annoying one.

The start and choke controls are mounted on the engine cover low down on the driver's left. This is a reasonable position for the rarely used choke, but the starter, which is cable-operated and has a stiff action, is difficult to use and would be almost impossible for someone wearing gloves or having really cold hands. Solenoid starter operation from the dashboard would be much better.

Standard Mirrors Two circular exterior mirrors are fitted as standard, but an interior mirror would be of advantage to make full use of the two windows in the rear doors. The side • loading door on the van had hinges projecting outside the body. These could, I feel, come to grief on kerbside obstructions.

Both the engine and body of the van were quiet, the only obtrusive noise being,sundry squeaks from the rubber bushes in the front-suspension units when running in dry weather. • ' Operators will find the engine in the 1-tonner easy to maintain. There is a surprising amount of space in the engine compartment, and two detachable panels, each secured by seven set-screws, expose the sides of the unit when removed. The main engine -cover is hinged at the front and held down by two rubber toggles. For routine maintenance it is hinged forward and held by a check wire, but can be removed completely after pulling out the hinge pins. With the cover hinged forward, free access is given to the radiator cap, sump dipstick,, sparking plugs, contact breaker, carburetter, oil filter, coil and dynamo-adjustment bracket.

The oil-bath air cleaner lies directly under the near-side panel which, when removed, allows the dynamo to be reached. The starter, which is mounted on this side of the engine, can be worked on more easily from beneath the vehicle. The petrol filter and the distributor are on the off side of the engine and are exposed by removal of the panel above them.

A circular trap in the front of the van floor gives access to the gearbox dipstick, work on the gearbox necessitating removal of the unit. The rear axle has a combined filler and level plug.

Brake adjustment is simple by means of screw-headed snail cams reached through apertures in the wheel discs. Tubular jacking points are provided at each wheel, and a special jack is included in the standard, sparse, toolkit.

The standard van with hinged doors costs £499 with a petrol engine, or -£611 in oil-engined form. Models with sliding cab doors cost an extra £5. A side-loading door (suitable only for vans with hinged cab doors) costs £16, and painting in any oneof five standard finishes is also £16.