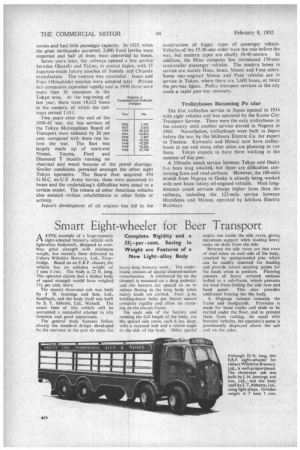

Smart Eight-wheeler for Beer Transport

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

Complete Rigidity and a 331-per-cent. Saving in Weight are Features of a New Light-alloy Body

A FINE example of a large-capacity eight-wheeled brewer's vehicle with light-alloy bodywork, designed to combine great strength with minimum weight, has recently been delivered to Ushers Wiltshire Brewery, Ltd., Trowbridge. Based on an ELF, chassis, the vehicle has an 'unladen weight of 7 tons I cwt. The body is 22 ft. long. The operator claims that a timber body of equal strength would have weighed, 33i per cent. more.

The special three-seat cab was built by .1 H. Jennings and Son, Ltd., Sandbach, and the body itself was built by S. T. Abbotts, Ltd., Walsall. The smart lines of this vehicle will be accounted a successful attempt to ally function and good appearance.

The general body features follow closely the standard design developed by the operator in the past six years for

heavy-duty brewery work. 1-he underframe consists of special channel-section cross-hearers. A reinforced lip on the channel is mounted on a deep pedestal, and the bearers arc spaced so as to reduce flexing in thc long body when heavy loads are carried. Four -A-in. holding-down bolts per bearer ensure complete rigidity and allow no creeping on the chassis frame.

On each side of the bearers and running the full length of the body, are the special side raves, each 6 ins, deep, with a recessed web and a return angle to the side of the body. Other special angles run inside the side raves, giving maximum support when loading heavy casks on skids from the side.

Between the side raves are two rows of steel tubes on each side of the body, attached by spring-loaded pins which can be readily removed for loading and provide lateral securing points for the loads when in position. Flooring consists of heavy serrated sections bolted to a sub-frame, which prevents the load from fouling the side rave and head panel. This also provides additional bracing for the body.

A 10-gauge valance conceals the frame and mudguards. Provision is made for hand trucks and skids to be carried under the floor, and to prevent them from rattling. As usual with brewers' vehicles, the operator's name is prominently displayed above the cab and on the sides.