SIMPLE MECHANICS

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

The compression ignition engine, 1

IN 1892 German engineer Dr Rudolf Diesel, took out a patent for an engine which relied on the heat generated during compression to ignite the fuel. Two years earlier a British engineer, Herbert Ackroyd Stuart, patented an engine where air was compressed in the cylinder and liquid fuel injected into it by means of a pump.

Which of these should receive the credit for inventing the compression ignition engine is questionable but there is no doubt that the term "diesel engine" is the one in common use today.

The compression ignition engine is similar in many ways, in its general construction, to the petrol engine. The main difference is in the way the fuel is introduced into the cylinder and the manner in which it is ignited. Most diesel engines operate on the four-stroke cycle, although the two-stroke type, dealt with later, received a fillip with the introduction by Bedford of the GM two-stroke diesel in its TM trucks.

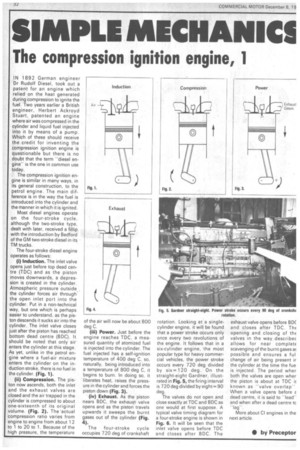

The four-stroke diesel engine operates as follows: (i) Induction. The inlet valve opens just before top dead cen tre (TDC) and as the piston moves downwards, a depression is created in the cylinder.

Atmospheric pressure outside.

the cylinder forces air through' the open inlet port into the cylinder. Put in a non-technical way, but one which is perhaps easier to understand, as the pis ton descends it sucks air into the cylinder. The inlet valve closes just after the piston has reached bottom dead centre (BDC). It should be noted that only air enters the cylinder at this stage. As yet, unlike in the petrol engine where a fuel-air mixture enters the cylinder on the induction stroke, there is no fuel in the cylinder. (Fig. 1).

(ii) Compression. The piston now ascends, both the inlet and the exhaust valves are closed and the air trapped in the cylinder is compressed to about one-sixteenth of its original volume. (Fig. 2). The actual compression ratio varies from engine to engine from about 12 to 1 to 20 to 1. Because of the high pressure, the temperature

of the air will now be about 800 deg C.

(iii) Power. Just before the engine reaches TDC, a measured quantity of atomized fuel is injected into the cylinder. The fuel injected has a self-ignition temperature of 400 deg C, so, naturally, being introduced into a temperature of 800 deg C, it begins to burn. In doing so, it liberates heat, raises the pressure in the cylinder and forces the piston down (Fig. 3).

(iv) Exhaust. As the piston nears BDC, the exhaust valve opens and as the piston travels upwards it sweeps the burnt gases out of the cylinder (Fig. 4).

The four-stroke cycle occupies 720 deg of crankshaft rotation. Looking at a singlecylinder engine, it will be found that a power stroke occurs only once every two revolutions of the engine. It follows that in a six-cylinder engine, the most popular type for heavy commercial vehicles, the power stroke occurs every 720 deg divided by six= 120 deg. On the straight-eight Gardner, illustrated in Fig. 5, the firing interval is 720 deg divided by eight= 90 deg.

The valves do not open and close exactly at TDC and BDC as one would at first suppose. A typical valve timing diagram for a four-stroke engine is shown in Fig. 6. It will be seen that the inlet valve opens before TDC and closes after BDC. The exhaust valve opens before BD( and closes after TDC. ThE opening and closing of thE valves in the way. describe( allows for near completE scavenging of the burnt gases aE possible and ensures a ful change of air being present ir the cylinder at the time the fue is injected. The period wher both the valves are open wher the piston is about at TDC iE known as "valve overlap" When a valve opens before e dead centre, it is said to "lead"' and when after a dead centre tc "lag".

More about Cl engines in the next article,

• by Preceptor