Atkinson/Dyson 30-ton-gross artic

Page 52

Page 53

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

TT is seldom that I have encountered a vehicle with two such distinctly different sides to its character as the Atkinson T3046C/Dyson 30-ton-gross artic which I have just tested.

On normal roads the performance was as one would expect from a vehicle of this weight and length—over 40 ft.; somewhat difficult to put around the bends on country roads but, as a result of the use of a Cummins 212 b.h.p. engine, endowed with plenty of power.

The Atkinson was quite docile, rather than sparkling, in traffic. As soon as it got onto the motorway, however, it seemed to shake itself, put its head down and get on with the job. If ever a vehicle was a natural for motorway operation I would say this is it. The test vehicle seemed to confirm its pleasure at being on the motorway by returning the excellent figure of 8.9 m.p.g. at an average speed of 42.8 m.p.h. (the maximum speed was 62 m.p.h.) compared with 7.2 m.p.g. for normal-road running at up to 40 m.p.h., this also being a good result. Braking performance was found to be excellent, the figures obtained being better than any vehicle I have previously tested at a similar gross weight. Also, the times obtained for acceleration would not have disgraced a vehicle running at the previous maximum gross weight of 24 tons.

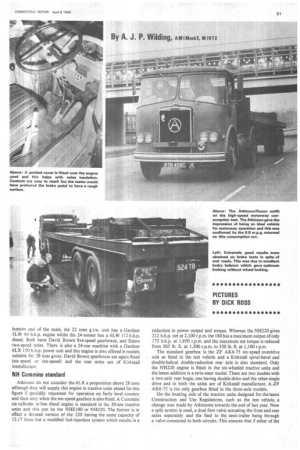

The Atkinson T3046C tested comes from the company's Silver Knight range of tractive units which include fourand six-wheel models for gross weight ratings of from 22 tons to 32 tons. At the bottom end of the scale, the 22 tons g.t.w. unit has a Gardner 5LW 94 b.h.p. engine whilst the 24-tonner has a 6LW 112 b.h.p. diesel. Both have David Brown five-speed gearboxes, and Eaton two-speed axles. There is also a 24-ton machine with a Gardner 6LX 150 b.h.p. power unit and this engine is also offered in models suitable for 28 tons gross. David Brown gearboxes are again fitted (six-speed or ten-speed) and the rear axles are of Kirkstall manufacture.

NH Cummins standard

Atkinson do not consider the 6LX a proposition above 28 tons although they will supply this engine in tractive units plated for this figure if specially requested for operation on fairly level country and then only when the ten-speed gearbox is also fitted. A Cummins six-cylinder in-line diesel engine is standard in the 30-ton tractive units and this can be the NHE180 or NH220. The former is in effect a derated version of the 220 having the same capacity of 12.17 litres but a modified fuel-injection system which results in a reduction in power output and torque. Whereas the NH220 gives 212 b.h.p. net at 2,100 r.p.m. the 180 has a maximum output of only 173 b.h.p. at 1,950 r.p.m. and the maximum net torque is reduced from 585 lb. ft. at 1,300 r.p.m. to 520 lb. ft. at 1,100 r.p.m.

The standard gearbox is the ZF AK6-75 six-speed overdrive unit as fitted in the test vehicle and a Kirkstall spiral-bevel and double-helical double-reduction rear axle . is also standard. Only the NH220 engine is fitted in the six-wheeled tractive units and the latest addition is a twin-steer model. There are two models with a two-axle rear bogie, one having double-drive and the other single drive and in both the axles are of Kirkstall manufacture. A IF AK6-75 is the only gearbox fitted in the three-axle models.

On the braking side of the tractive units designed for the latest Construction and Use Regulations, such as the test vehicle, a change was made by Atkinsons towards the end of last year. Now a split system is used, a dual foot valve actuating the front and rear axles separately and the feed to the semi-trailer being through a valve connected to both circuits. This ensures that if either of the circuits becomes defective the braking is still applied to the semitrailer and the undamaged circuit. The secondary side of dual diaphragm brake chambers at the front axle and the "auxiliary" semi-trailer connection are pressurized through a hand-control valve on the steering column to provide the secondary brake system required and the multi-pull handbrake is a purely mechanical unit.

Dyson semi-trailer The Dyson semi-trailer used for the tests was a standard 32 ft. 6 in. long platform model from the Newloader range having the DNR four-spring suspension. This was introduced about two years ago and a report of evaluation tests with an unladen semitrailer was published in COMMERCIAL MOTOR (March 27, 1964).

The effectiveness of the design in eliminating wheel hop and spring chatter was demonstrated adequately on these tests and this is the result of the incorporation of two brake-torque cancelling systems. The rear ends of the springs are inter-connected on each side by non-reaction-type linkages and each axle is located axially by radius rods, two below each axle under the springs and one above at the centre. The axles are tubular and have S-cam brakes, in the case of the test unit, 15.5 in. diameter by 7 in. wide. Brake actuation is by dual-diaphragm brake chambers all round to provide for the service and secondary brake systems.

The output was a little overloaded for the test, gross weight coming out at 30 tons 17.75 cwt. when two people were in the cab. The actual load carried was 20 tons 4.25 cwt. so keeping to the legal limit would allow a payload of just about 19.5 tons to be carried. First tests carried out were on braking in spite of the day being a very wet one but there was no indication that the weather would get any better, quite the reverse in fact. An airfield that Atkinson now use for braking testing was the scene for the tests and although the runway surfaces were wet, extremely good stopping distances for all the max imum-pressure tests were obtained.

Excellent brake balance .

This was entirely due to the excellent brake balance on the outfit which resulted in very good retardation being possible without wheel locking. The tractive unit wheels never locked and only on one or two occasions was there any locking of the semi-trailer wheels, this being only slight. The way in which Atkinson have obtained the correct brake balance is by making the effort at the front wheels sufficiently high for these brakes to do their fair share of work. This was confirmed in tests of the secondary system in which the outer axles are braked.

It was not noticeable that there was any appreciable delay in application although this can be so with these types of system. But as the Atkinson had an adequate front-brake effort there was a strong feeling of braking immediately the treadle was applied, even though there must have been some delay in the air getting from the tractive unit to the semi-trailer brakes. There could not have been much thoUgh, because the outfit stopped in 118 ft. from 30 m.p.h.—Atkinson had fixed up' the brake test equipment to be actuated by operation of the hand-valve—and the actual efficiency of 26 per cent that this represents compares favourably with the maximum retardation of 41 per cent obtained with the Tapley meter.

No figure for efficiency could be recorded for the mechanical handbrake because it did not reach the minimum on the Tapley meter, which does not register below 10 per cent. This was not unexpected by the Atkinson personnel accompanying me on the test who said that the important thing was that the unit would hold the vehicle on a required incline. This was checked on Parbold Hill (as dealt with later in this report) and found to be the case.

Later, when the road surface was drier repeat service-brake tests were carried out without any change in the performance being evident and Tapley meter readings for maximum deceleration were still the same at 70 per cent from 20 m.p.h. and 68 per cent from 30 m.p.h.

Fuel consumption tests Initial fuel consumption tests were carried out on a run from Preston southwards on poor class roads with many steep hills and difficult bends. The Atkinson was definitely not intended for this sort of terrain and due to a considerable amount of low-gear work it was not surprising that a fuel consumption of just under 6 m.p.g. was obtained. After the excellent consumption of 8.9 m.p.g. had been returned on the M6 motorway test—out and return between A5329 and Bamber Bridge—a normal-speed consumption run on a road more typical of British trunk roads and more similar to the type of route normally used for COMMERCIAL MOTOR road tests was seen to be even more desirable.

Such a route was found and this consisted of a 16.2 mile outand-return trip on the A6 north of Preston. There was a good turn-round point at the north end and the A6 here is of a gently undulating character with only one or two short and sharp inclines. I would expect the figure of 7.2 m.p.g. returned with the outfit to be obtainable on most types of trunk roads.

Performance has not been sacrificed on the Atkinson to obtain good fuel consumption and this was confirmed not only by the general "feel" of the vehicle on normal running but also by the good times obtained for acceleration. Both through-the-gears and direct-drive times would not have disgraced many a 24-tongross outfit and were better than the times obtained on previous tests of 30-ton artics by COMMERCIAL MOTOR. One of the reasons for the good acceleration times on the through-the-gears runs was the admirable matching of the gearbox to the engine. Maximum speeds in the intermediate gears were 7, 11, 18, 28 and 45 m.p.h. whilst the maximum in overdrive was 62 m.p.h. These figures take into account a speedometer inaccuracy on the test vehicle of 2 per cent fast at 30 m.p.h. and 6 per cent fast at 60 m.p.h.

A good performance was also put up by the Atkinson on the hill-climbing tests -which took place on Parbold Hill which is 0.75 mile long and has an average gradient of 1 in 12 with the maximum 1 in 6.5 on one stretch. Only 4 mm. 35 sec. was required for a full-power ascent and the minimum speed on the climb was 8 m.p.h. The lowest gear used was second and the time spent in it was 1 min. 28 sec. As the Atkinson engine-coolant system incorporates a header tank it was not possible to take direct readings of the rise in temperature but a dash-mounted gauge showed that this had gone up from 76°C (168°F) to 82°C (180°F) in an ambient temperature of .5°C (35°F).

Brake-fade resistance Brake-fade resistance was checked on a run down the hill at 20 m.p.h. with direct-drive engaged. The normal practice is to make the run in neutral but this is not considered safe when grossing 30 tons, primarily because insufficient air will be provided when the engine is ticking over to keep the reservoir at a high enough pressure. At the bottom of the hill, a maximum pressure stop from 20 m.p.h. produced the Tapley-meter reading of 63 per cent which shows that there should be no problem with fade.

Restart tests on the steepest section of the hill were completed successfully, in first when facing up and in reverse when facing down the slope. It was not possible to start in second up the hill; in spite of deliberate clutch slip the outfit could not be induced to pick up speed. The handbrake was also checked on the steepest section and here the claims made by the Atkinson people at the time of the series of brake tests were confirmed—but only just! It was possible to hold the vehicle on the handbrake both facing up and facing down only with the help of the footbrake. It was completely impossible to stop the vehicle from rolling back by applying the handbrake without this help.

During all the tests of the Atkinson a slight amount of smoke was present in the exhaust. It varied during the time I was with the vehicle from being just noticeable to fairly dark during the hill-climb tests. This is the only complaint that can be levelled at the design from a mechanical point of view and the fact that the Cummins engine is prone to smoke has probably led Atkinson to fit a transverse silencer and exhaust outlet ahead of the front wheels on current production. The vertical unit behind the cab as on the test vehicle would blow smoke into the upper deck of buses.

Although not up to the standard on many vehicles now in production in Britain, the Atkinson cab is fairly roomy and comfort able and gives reasonably good visibility. Heating and demisting equipment fitted in the test vehicle was quite adequate on the cold and wet days that the test took place; the conditions did not lend themselves to assessment of the ventilation characteristics but these appear to be about standard.

Easy to drive My main impression of the test vehicle was that it is an easy vehicle to drive and the light and responsive steering and good braking was certainly a help in this. The design of the arms on which the rear-view mirrors are mounted is good and prevented vibration but the fact that they are rigid could give rise to damage if a driver is manoeuvring in tight corners. The mirror heads were of a good size on the test vehicle but I would have preferred a slightly convex glass instead of the plane-surface ones used, as the field of vision particularly from the nearside mirror was somewhat limited.

Insulation against noise was found to be reasonably effective although I have driven in quieter machines in this class and one point I would like to see attended to is the fitting of a brake treadle with a rough surface. My foot slipped off the smooth treadle on one of the brake tests and although I know there is no need to press hard as only a valve is being opened, it is a natural reaction to do so when trying to stop in the shortest distance.

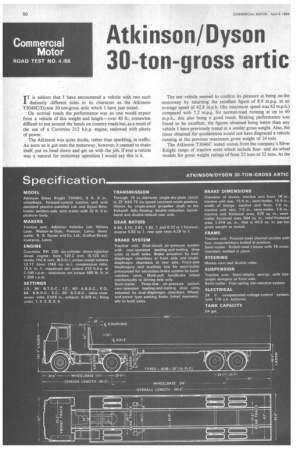

ATKINSON/DYSON 30-TON-GROSS ARTIC

Specification

MODEL Atkinson Silver Knight T3046C, 9 ft. 6 in.wheelbase. forward-control tractive unit with standard plastics-panelled cab and Dyson New. loader tandem-axle semi-trailer with 32 ft. 6 in, platform body.

MAKERS Tractive unit: Atkinson Vehicles Ltd., Winery Lane, Walton-le-Dale, Preston, Lancs. Semitrailer : R. A. Dyson and Co. Ltd., Grafton Street. Liverpool, Lancs.

ENGINE Cummins NH 220 six cylinder direct injection diesel engine; bore 130.2 mm. 15.125 in.): stroke 152.4 mm. (6.0 in.); piston-swept volume 12.17 litres (743 cu. in.); compression ratio, 15.5 to 1; maximum net output 212 b.h.p. at 2,100 r.p.m.; maximum net torque 585 lb. ft. at 1,300 r.p.m.

SETTINGS

1.0., 36-' B.T.D.C.; IC., 40^ A.B.D.C.; EQ., 64 B.B.D.C.: E.C., 26A.T,D.C.: valve clearances, inlet, 0,016 in., exhaust, 0.029 in.: firing order, 1. 5.3. 6. 2.4.

TRANSMISSION Through 18 in.-diameter single-dry-plate clutch to ZF AK6-75 six-speed constant-mesh gearbox, thence by single-piece propeller shaft to the Kirkstall fully floating double-reduction (spiralbevel and double-helical) rear axle.

GEAR RATIOS 6.44, 4.10, 2.61, 1,62, 1 and 0.72 to 1 forward; reverse 5.92 to 1, rear axle ratio 6.28 to 1.

BRAKE SYSTEM Tractive unit: Dual-circuit air-pressure system with cam-operated leading-and-trailing shoe units at both axles. Brake actuation by dualdiaphragm chambers at front axle and singlediaphragm chambers at rear axle. Front-axle diaphragms and auxiliary line for semi-trailer pressurized for secondary-brake system by hand. reaction valve. Multi-pull handbrake linked mechanically to driving axle only.

Semi-trailer: Three line air-pressure system cam-operated leading-and-trailing shoe units actuated by dual diaphragm chambers. Wheeland-screw type parking brake linked mechanic. ally to both axles. BRAKE DIMENSIONS Diameter of drums, tractive unit front, 16 in., tractive unit rear, 15.5 in., semi-trailer, '15.5 in.; width of linings, tractive unit front, 5.0 in., tractive unit rear, 7.0 in., semi-trailer, 7.0 in.; tractive unit frictional area, 570 sq. in., semitrailer frictional area, 844 sq. in., total frictional area, 1,414 sq. in., that is 45.9 sq. in. per ton gross weight as tested.

FRAME Tractive unit: Pressed-steel channel-section with four crossmembers bolted in position. Semi-trailer: Rolled-steel I-beam with 16 crossmembers welded in place.

STEERING Marles cam and double roller.

SUSPENSION Tractive unit: Semi-elliptic springs with telescopic dampers at front axle.

Semi-trailer: Four spring non-reactive system.

ELECTRICAL 24 V. compensated-voltage-control system, with 110 a.h. batteries.

TANK CAPACITY 54 gal.